Anodized Titanium Screws

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

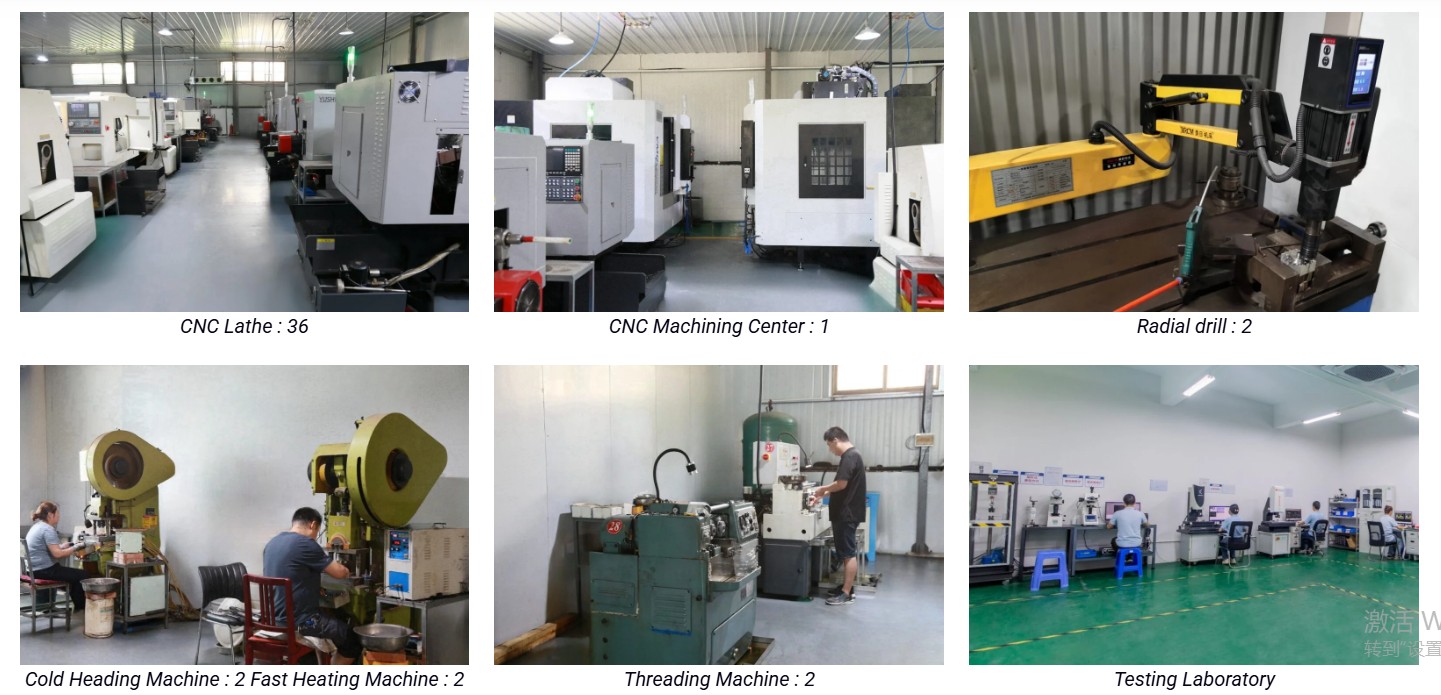

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| Moq | In stock:50pcs Custom-made:500pcs |

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Wstitanium Custom Anodized Titanium Screws – In-house Service

Wstitanium in-house anodized titanium screws add a bright and durable surface to your titanium fasteners. Precisely control the parameters of anodizing voltage, current, electrolyte concentration and temperature, and provide 45 options such as blue, purple, gold, green, black, etc. Covering the entire anodized titanium series – let your titanium screws stand out while maintaining high strength and weight advantages.

Advantages of Anodized Titanium Screws

Strong corrosion resistance: The oxide film formed by anodizing has good chemical stability, effectively blocking the external corrosive medium from contacting the titanium screw matrix, greatly improving the corrosion resistance of the screws in various harsh environments, such as in the ocean, chemical industry, etc.

Good wear resistance: The oxide film has a high hardness, which can enhance the wear resistance of the titanium screw surface, reduce the wear caused by friction during use, and increase the service life of the screw, especially for occasions where disassembly and installation are often required.

Beautiful appearance: Get rich and diverse colors to meet the requirements of different users for appearance, making the product more decorative, in some fields with high requirements for appearance, such as electronic products, high-end furniture, jewelry, etc.

Improved high temperature resistance: The oxide film can improve the high temperature resistance of titanium screws to a certain extent, so that it can better maintain its own mechanical properties and shape stability in high temperature environments, and is suitable for some high temperature working environments, such as aerospace, automobile engines and other fields.

Application

Aerospace: Titanium screws are light in weight, high in strength, and have good corrosion resistance. After anodizing, they can not only meet the strict performance requirements of aerospace components, but also can be marked and distinguished by oxide films of different colors. Different parts, but also help to improve the appearance quality and weather resistance of the parts.

Electronic field: In some high-end electronic products, such as laptops, mobile phones, tablets, etc., they are used to fix internal parts. Anodized titanium screws can not only provide reliable connections, but also improve the overall quality and grade of the product due to their beautiful appearance and good corrosion resistance.

Automobile: It can be used for the connection of parts in automobile engines, chassis, body and other parts. Its lightweight characteristics help to reduce the weight of the car and improve fuel economy. At the same time, the screws after anodizing have good corrosion resistance and wear resistance, and can adapt to the complex use environment of the car.

Marine field: In marine projects such as ships and offshore oil platforms, it is used to connect and fix various metal structural parts. The seawater corrosion resistance of titanium screws and the protective performance after anodizing can effectively prevent the screws from rusting and corroding in the marine environment, ensuring the safety and stability of the structure.

Building decoration: In the decoration projects of some high-end buildings, such as curtain walls, doors and windows, interior decoration, etc., it is used to connect and fix decorative parts. The beautiful color and good corrosion resistance of anodized titanium screws can make architectural decoration more beautiful and durable.

Sports equipment field: Such as bicycles, golf clubs, mountaineering equipment, etc., the lightweight and high-strength characteristics of titanium screws can improve the performance of sports equipment, and the appearance after anodizing can also meet consumers’ requirements for product aesthetics.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Burnt Titanium Wheel Bolt

-

Titanium Fasteners

Rainbow Titanium Bolt For Cars