Colored Titanium Springs

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a high-performance elastic element, titanium springs have broken through the application limitations of traditional steel springs in high-end fields with their core advantages of corrosion resistance, lightweight, high fatigue life, wide temperature range adaptability and excellent biocompatibility. They have become an indispensable key component in industries such as aerospace, marine engineering, medical care, chemical industry, and new energy.

| Product Name | Custom Titanium Springs |

| Finishing | Anodized, Burnt, Polished, PVD, etc. |

| Dimension | Customized, Follow Drawings |

| Material | Grade 5 Titanium |

| Standard | ASTM B265, ASTM B337, EN 13819, EN ISO 14704 |

| MOQ | 100pcs |

| Color | Natural,Gold,Black,Customized Colors Available. |

| Service | Customized OEM/ODM Service |

| Sample | Available |

| Features | Light Weight,Excellent Resistance,Anti – Corrosion,Excellent Mechanical Strength etc. |

| Quality Inspection | 1.ISO 9001:2015 |

| 2. Mechanical properties test. | |

| 3. Inspection ensure the materials meet destructive and non – destructive test according to industry and customer specification. | |

| Applications | Bicycle, Motorcycle, Automobile, Shipbuilding, Chemical Industry. |

Advantages of Titanium Springs

Compared to traditional steel and stainless steel springs, titanium springs offer significant advantages in material properties and performance. These advantages enable them to adapt to more complex and demanding working environments, which can be summarized as follows:

(I) Excellent Corrosion Resistance

In seawater environments, steel springs typically show noticeable rust within a few months. However, titanium springs can withstand long-term immersion in seawater (years or even decades) without corrosion. Therefore, they are widely used in marine engineering applications, such as subsea probes and offshore platform connectors. In the Chemical Industry, titanium springs offer far superior corrosion resistance to strong acids and bases like sulfuric acid, hydrochloric acid, and nitric acid, ensuring long-term stable operation of equipment in harsh chemical environments. Furthermore, titanium springs effectively resist corrosion in environments such as humid industrial atmospheres and sweat (as seen in medical implants), extending their service life.

(2) Balancing Lightweight and High Strength

Titanium has a density of only 4.5g/cm³, far lower than steel (7.85g/cm³) and copper (8.96g/cm³). However, titanium alloys (such as TC4 titanium alloy) can achieve a tensile strength exceeding 900MPa, comparable to high-strength steel. This “low density, high strength” characteristic allows titanium springs to weigh only 50%-60% of steel springs for the same load capacity.

(3) Excellent Fatigue Life

Fatigue failure is one of the main causes of spring failure, especially under long-term, repeated load conditions. Springs are prone to fracture due to the initiation and propagation of fatigue cracks. Titanium and its alloys possess excellent toughness and fatigue resistance. Their fatigue strength to tensile strength ratio (fatigue ratio) is high, typically between 0.4-0.5, superior to that of ordinary steel (approximately 0.3-0.4).

(4) Good High and Low Temperature Adaptability

Titanium and its alloys have a wide operating temperature range, maintaining stable mechanical properties from -253°C (liquid nitrogen temperature) to 600°C. At low temperatures, titanium springs maintain excellent elasticity and strength; at high temperatures, they resist oxidation and creep.

(5) Excellent Biocompatibility

Pure titanium and some titanium alloys (such as TC4 titanium alloy) possess excellent biocompatibility. The oxide film on their surfaces forms a stable bond with human tissue, preventing absorption or the generation of harmful ions. Therefore, titanium springs are widely used in medical implants, such as cushioning springs for artificial joints, elastic components for orthopedic fixation devices, and traction springs for dental braces.

Wstitanium’s Strong Manufacturing Capabilities

Quality Inspection

After manufacturing, titanium springs undergo rigorous quality inspection to ensure they meet custom specifications. Inspection items primarily include:

Dimensional Inspection: Calipers, micrometers, projectors, and other equipment are used to inspect dimensional parameters such as wire diameter, outer diameter, inner diameter, free length, and number of turns to ensure compliance with tolerances. For complex, special-shaped springs, three-dimensional scanning is performed using a coordinate measuring machine to fully verify shape accuracy.

Mechanical Property Testing

Using a spring stiffness testing machine, a specific load is applied and deformation is measured to calculate the spring stiffness and verify compliance with design requirements.

Fatigue Life Testing: Testing is performed on a fatigue testing machine using the designed alternating load and number of cycles to observe for cracks or fractures and ensure that fatigue life meets the specified requirements.

Static Load Testing: A static load of 1.5 times the working load is applied for 10-30 minutes. After unloading, the permanent deformation of the spring is measured. Permanent deformation is typically required to be ≤0.5% of the free length to prevent permanent failure during use.

Surface Quality Inspection: Observe the spring surface visually and microscopically (magnification 10-50x) to check for defects such as cracks, scratches, and coating loss. For medical springs, sterility testing and biocompatibility testing (such as cytotoxicity and hemolysis tests) are required.

Material Re-inspection: Randomly sample samples for chemical composition analysis and metallographic observation to ensure the correct material grade and that the metallographic structure after heat treatment (such as the distribution of secondary phases after aging) meets requirements, ensuring stable mechanical properties.

Related products

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

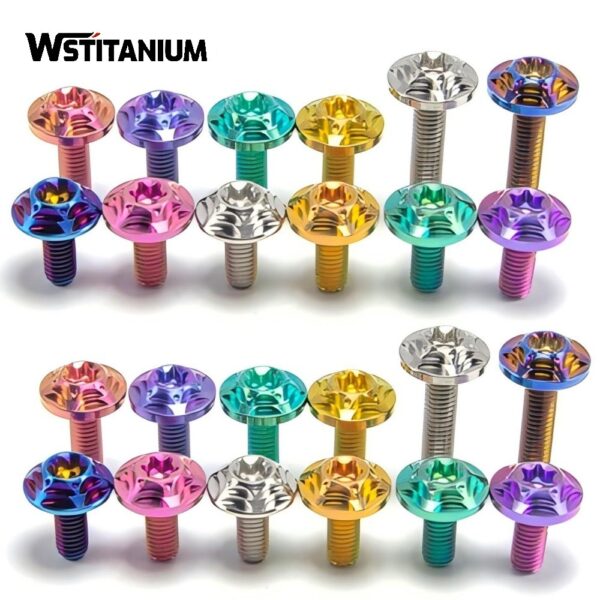

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Burnt Titanium Wheel Bolt

-

Titanium Fasteners

Rainbow Titanium Bolt For Cars