Custom Manufacturing Titanium Screws

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a basic and key fastening part, the performance and quality of titanium screws have a vital impact on the reliability of various products and projects. Titanium screws are widely used in many high-end fields such as aerospace, medical equipment, automotive industry, high-end electronic products, motorcycles, etc. due to their high strength, low density, excellent corrosion resistance, good biocompatibility and other characteristics.For Wstitanium, the customized titanium screw business is not only an important measure to meet the diversified needs of the market, but also a key way to demonstrate its own technical strength and service capabilities.

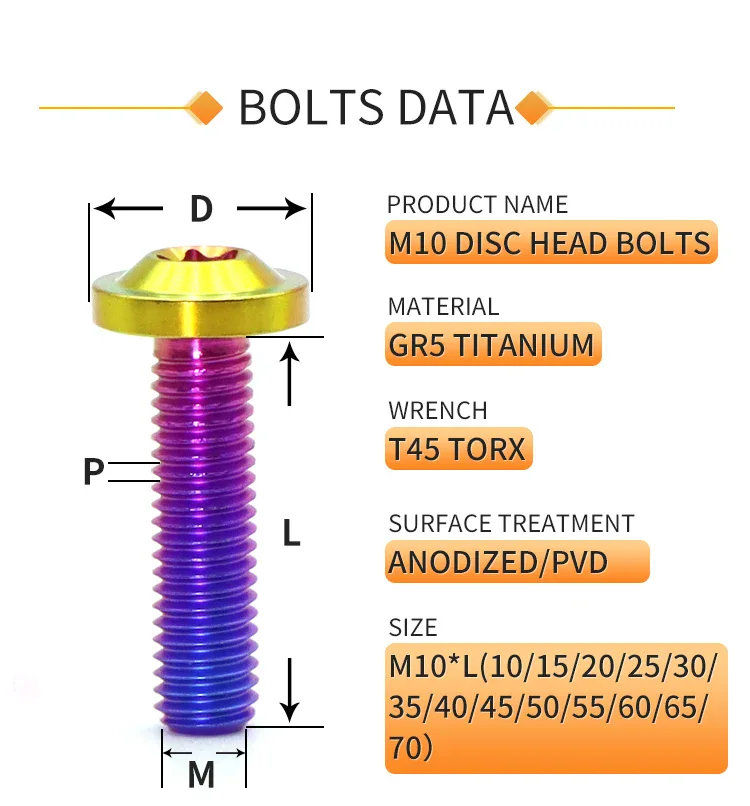

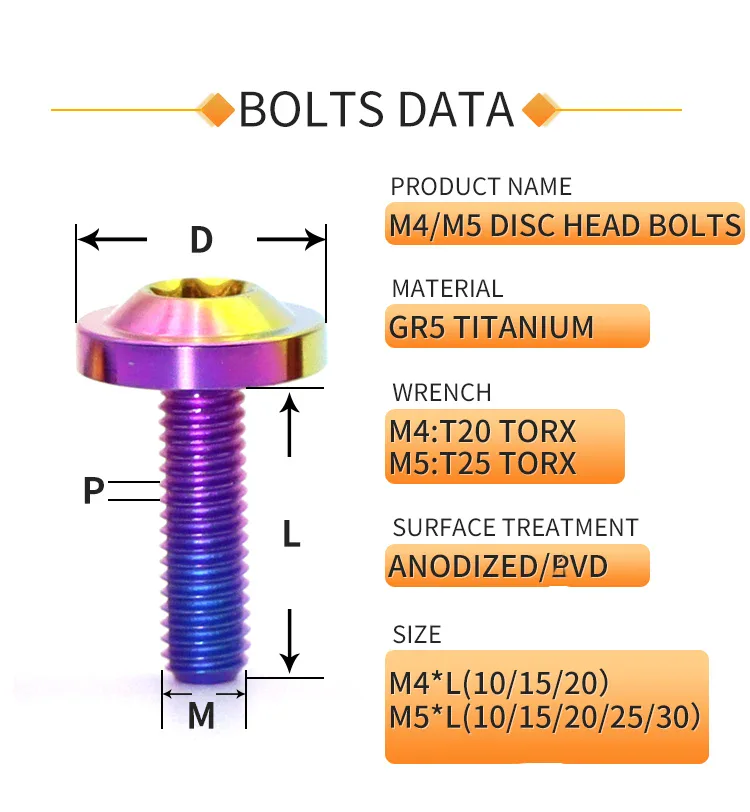

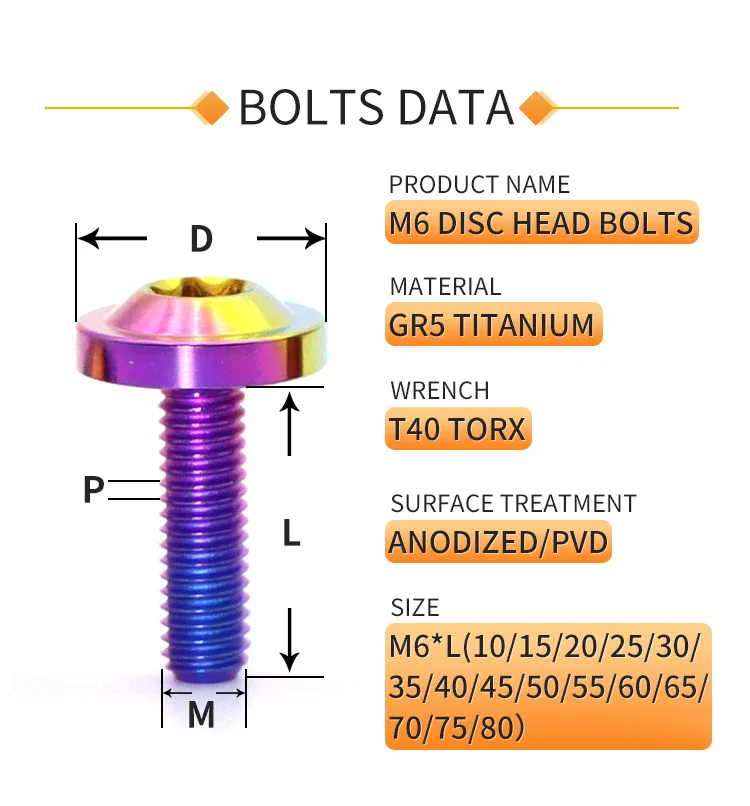

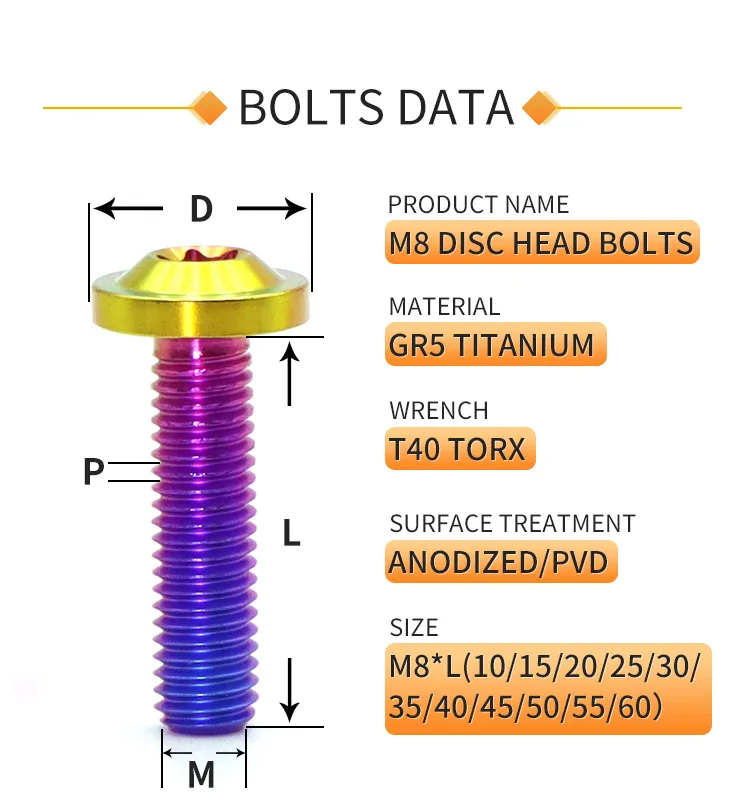

| Product | Custom Titanium Screws | Head Type | Flat/Hex/Pan/Hexagonal etc |

| Size | M2-M30,or Customized | Thread | UNC |

| Material | GR5 titanium | Color | Anodized various colors, optional |

| Standard | GB, DIN, ISO, ANSI/ASTM, JIS etc | Material | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 Titanium |

| Non-standards | OEM is available, according to drawing or samples | Application | Aerospace, medical, chemical, automobile, motorcycle, bicycle |

| Finish | Polishing+Anodizing | Mark | Customer’s requirement |

| Package | Polybag packing+carton packing or according to requirement | Application | Aerospace, medical, chemical, automobile, motorcycle, bicycle |

Pan Head: The head of the pan head titanium screw is round and has a more beautiful appearance. This shape makes the surface of the screw smoother after tightening, which is suitable for some occasions with high requirements for appearance and do not need to withstand large torque, such as the fastening of the shell of electronic products and the connection of furniture decorative parts. The arc design of its head can avoid scratching the operator or other parts during use.

Flat Head: The head of the flat head titanium screw is flat. When the screw is screwed into the material, the head can be flush with the surface of the material, making the entire connection surface relatively flat. It is often used in occasions where a flat surface is required, such as some equipment that needs to install a panel. The panel is fixed to the main body of the equipment through a flat head screw, which will not affect the flatness and beauty of the panel. It is widely used in industries such as building decoration and instrument manufacturing.

Countersunk Head: The head of the countersunk titanium screw is conical. When the screw is screwed into the material, the head will sink below the surface of the material, making the connection surface completely flat. This type of screw is suitable for occasions with extremely high requirements for surface flatness, such as the assembly of some precision parts in the aerospace field, where it is necessary to avoid surface protrusions to reduce air resistance or ensure a close fit between parts; in high-end furniture manufacturing, it is also often used in places where the screw head needs to be hidden to improve the overall aesthetics.

Hex Head: Hex head titanium screws have a distinct hexagonal head, which is convenient for tightening and loosening with tools such as wrenches. It can withstand large torques and is suitable for occasions that require high-strength fastening, such as the assembly of mechanical equipment and the connection of building structures. In industrial production, hex head screws are one of the most common types because they are easy to operate and have strong fastening force.

Socket Head: The head of the hex head titanium screw is a hexagonal groove inside, and a hex wrench is required for operation. Compared with the external hex head screw, its head size is relatively small and the appearance is more compact. It is often used in places where space is limited but high fastening strength is required, such as the compact structure inside electronic equipment, or some mechanical products with more delicate appearance requirements.

Unified Thread: Unified threads are still widely used in some specific industries and regions, especially in aerospace, automotive industry and other fields. The pitch and tooth angle of the unified thread are different from those of the metric thread, and its dimensioning is also in imperial units. Wstitanium can customize titanium screws with unified threads according to customer needs.

Self-tapping Thread: The thread of the self-tapping titanium screw has a special design, and its tooth profile is sharper, which can tap out threads and fasten on some softer materials (such as plastics, thin metal plates, etc.). This type of screw is widely used in electronic product housing assembly, furniture assembly and other situations where quick installation is required and the material is relatively soft. It does not require pre-drilling, which improves installation efficiency.

Related products

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs