Customized MMO Titanium Anodes

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

MMO titanium anode, also known as a dimensionally stable anode (DSA), is based on a pure titanium (TA1/TA2) substrate. Using precision technology, a catalytic layer of metal oxides, such as ruthenium, iridium, tantalum, and platinum, is applied to the surface. This creates a perfect blend of the corrosion resistance of the titanium substrate and the high catalytic activity of the oxide coating.

Compared to traditional graphite and lead anodes, MMO titanium anodes achieve several performance improvements: Their service life can reach years or even decades, more than 10 times that of graphite anodes. Furthermore, they improve the overall energy efficiency of electrolysis systems by 15%-25%. They completely eliminate the problem of electrolyte contamination caused by dissolution of conventional anodes. From ion-exchange membrane electrolyzers in the chlor-alkali industry to cathodic protection systems in marine engineering, and from advanced treatment of printing and dyeing wastewater to precision electroplating, MMO titanium anodes have become an indispensable core component in modern industrial electrochemistry.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Manufacturing MMO Titanium Anodes

The custom manufacturing of MMO titanium anodes involves a multidisciplinary approach, encompassing three core steps: substrate preparation, coating formulation development, and coating. The precision of each step directly determines the final electrode performance.

(I) Selecting Titanium Substrate

The quality of the titanium substrate (plate, mesh, wire, or tube) is essential for ensuring coating adhesion and electrode life.

Gr1/Gr2 grade titanium with a titanium content ≥99.7% is preferred. For high current density applications, titanium with a tensile strength ≥345 MPa is required.

(II) Forming

The titanium substrate is formed into a shape consistent with the design using CNC machining, laser cutting, water jet cutting, and other techniques.

(III) Cleaning the Titanium Substrate

A three-stage treatment process of “alkaline degreasing – acid rust removal – pure water cleaning” is used to remove surface grease, scale, and contaminants. Customized cleaning requires controlled acid concentration (a mixture of hydrofluoric acid and nitric acid in a ratio of 1:3-1:5) and treatment time (3-10 minutes).

(IV) Activation and Roughening

Electrochemical etching or sandblasting creates a microscopically rough surface to increase the coating contact area. For mesh anodes, alumina grit is sandblasted at a pressure of 0.3-0.5 MPa to achieve a surface roughness Ra of 1.5-3.0 μm. For precision rod anodes, electrochemical etching is used to create a uniform microporous structure, ensuring uniform coating adhesion.

(V) Customized Coating Formulation

The coating is the core function of the MMO titanium anode. Customized formulations must be precisely designed based on the electrolysis target (chlorine evolution, oxygen evolution, specialty catalysis) and the medium environment:

Chlorine Evolution System Formulation: For applications such as the chlor-alkali industry and seawater chlorination, a RuO₂-IrO₂-TiO₂ composite coating system is used. The chlorine evolution overpotential can be controlled to ≤1.36 V (vs. SHE) and can withstand high chlorine concentrations exceeding 300 g/L. By adjusting the molar ratio of Ru to Ir (typically 3:1-4:1), a balance between catalytic activity and coating stability can be achieved.

Oxygen Evolution System Formulations: Targeting applications such as hydrometallurgy and water electrolysis, we have developed IrO₂-Ta₂O₅ mixed oxide coatings, which reduce oxygen evolution overpotential by over 30% and achieve current efficiencies exceeding 90%. In acidic media, the Ta₂O₅ content should be increased to 40%-50% to enhance the coating’s acid corrosion resistance.

Specialty Functional Formulations: Targeting environmentally friendly wastewater treatment, we have adopted PbO₂-MnO₂-doped coatings to enhance hydroxyl radical generation and improve the removal rate of recalcitrant organic matter. For high-precision electroplating applications, we have selected platinum-group metal modified coatings to ensure coating thickness uniformity within ±3%.

(VI) Coating and Sintering

Coating directly affects coating uniformity and adhesion. Customized manufacturing requires a multi-step control process:

Coating Method: Planar electrodes are coated using dip coating, with a coating thickness tolerance controlled within ±0.5μm. Mesh electrodes are sprayed, ensuring uniform coverage within pores by adjusting the spray gun distance (15-20cm) and movement speed (5-8cm/s). Electrophoretic deposition is used for complex-shaped electrodes to achieve uniform coating.

Multi-layer Sintering Control: A “coating-drying-sintering” cycle is used, with each layer sintered at a temperature of 450-550°C and a holding time of 10-15 minutes. The cumulative coating thickness can be customized to 5-20μm. The sintering atmosphere must be oxidizing to prevent the reduction of metal oxides in the coating, which may affect catalytic performance.

Quality Inspection: Custom manufacturing requires additional quality control procedures, including coating adhesion testing (cross-hatch test ≥ 5B), coating thickness testing (multi-point measurement with an eddy current thickness gauge), and electrochemical performance testing (overpotential determination by linear sweep voltammetry) to ensure that each batch of products meets custom requirements.

Customization Types of MMO Titanium Anodes

Depending on the structural morphology, coating system, and application scenario, MMO titanium anodes can be customized into the following four types:

Mesh Anodes

Utilizing a porous weave, these anodes can have a customizable porosity of 60%-80%. Their surface area is 3-5 times greater than that of flat electrodes, making them suitable for electrolysis applications requiring efficient mass transfer. Typical specifications include a mesh size of 0.5-5mm and a titanium wire diameter of 0.3-2.0mm. Custom cutting can be performed to suit the size of the electrolytic cell. They are widely used in the chlor-alkali industry and electroplating wastewater treatment.

Rod Anodes

The base is a solid titanium rod with a diameter of 3.2-25mm and customizable lengths up to 1220mm or longer. The coating is primarily an IrO₂-Ta₂O₅ system. In seawater environments, a 12.7mm diameter rod anode can achieve a rated output current of up to 19.4A/m and a service life of up to 20 years, making it particularly suitable for cathodic protection of offshore wind turbine foundations.

Strip Anodes

Widths range from 6.35-25mm, thicknesses from 0.635-1.2mm, and lengths customizable up to 1000m. The surface is engraved with micron-scale grooves 0.1-0.3mm deep, increasing the specific surface area by three times. Customized versions with built-in composite conductive cores offer conductivity up to three times that of pure titanium, making them suitable for cathodic protection of tank floors and long-distance pipelines.

Special-Shaped Anodes

Customizable to suit equipment structures, these anodes can be designed in various shapes, including tubular, plate, and curved, utilizing 3D modeling to ensure a perfect fit. For applications such as protecting LNG storage tanks and reactor interiors, these special-shaped anodes provide 360° protection.

Ruthenium Anodes

Using RuO₂ as the core active ingredient and additives such as IrO₂ and TiO₂, these anodes offer superior chlorine evolution performance, achieving chlorine purity up to 99.98%. These anodes are specifically designed for the chlor-alkali industry.

Iridium Anodes

Using IrO₂ as the primary active ingredient and Ta₂O₅ for enhanced stability and a low oxygen evolution overpotential, these anodes are suitable for applications such as sulfate electrolysis and freshwater cathodic protection. Their coating loss rate is only 1-6 mg/A·a.

Platinum Anodes

The platinum coating has enhanced catalytic activity, making it suitable for high-end customized applications such as gold plating of precision electronic equipment and semiconductor cleaning, increasing the yield rate by 80%.

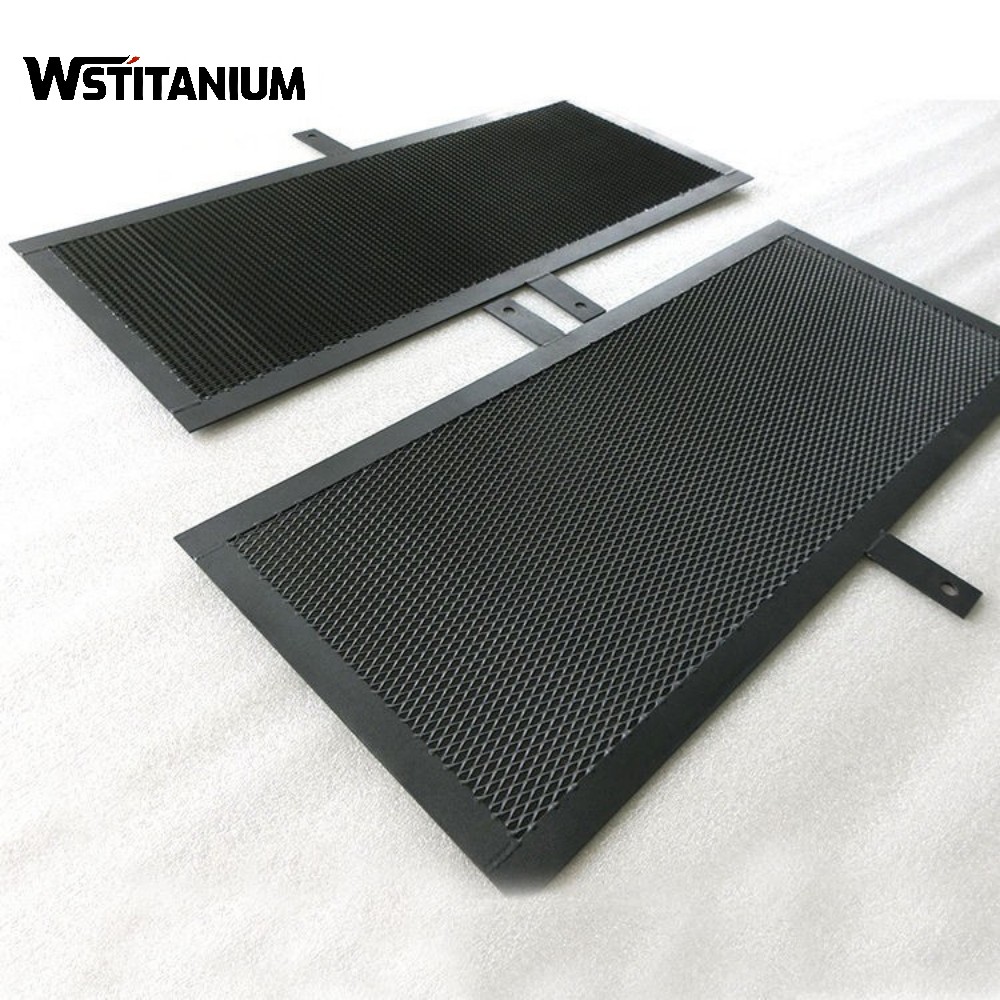

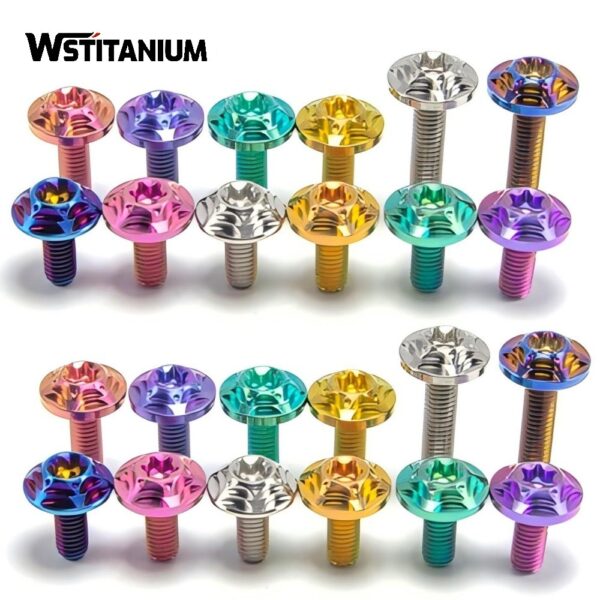

Related products

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt