Gr5 Titanium Wheel Bolts

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Wheel bolts, as core load-bearing components connecting wheels to axles, have a direct impact on vehicle safety, handling, and stability. While traditional steel wheel bolts offer lower costs, they suffer from inherent drawbacks such as high density, susceptibility to corrosion, and limited fatigue life. These limitations make them difficult to meet the stringent requirements for lightweight, high-strength, and long-life components in high-end automobiles, racing cars, and specialized vehicles. Gr5 titanium wheel bolts, with their perfect balance of high strength and low density, exceptional corrosion resistance, and superior fatigue strength, have proven their reliability in the aerospace industry and are now being gradually introduced into the automotive, motorcycle, and bicycle markets.

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

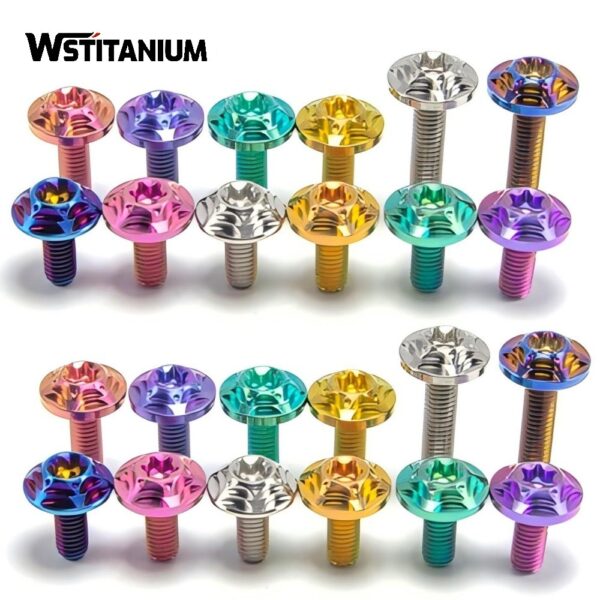

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Surface Treatment

Gr5 titanium inherently has excellent corrosion resistance, but surface treatment can further enhance its scratch and salt spray resistance while also meeting individual needs. Common surface treatments include:

Anodizing: The bolt acts as the anode and is placed in an electrolyte solution (such as sulfuric acid or oxalic acid). A direct current is applied to the bolt surface, forming an oxide film with a thickness of 5-20μm. This anodic oxide film not only enhances corrosion resistance but also allows for color control by adjusting the voltage (10-50V). For example, 10V produces silver, 30V produces blue, and 50V produces gold, meeting the personalized needs of the aftermarket.

Sandblasting: Diamond abrasive (80-120 mesh) is sprayed onto the bolt surface using a high-pressure airflow (0.5-0.8MPa) to create a uniform matte finish. Sandblasting removes scale and minor defects from the bolt surface, improving surface roughness (Ra 1.6-3.2μm), enhancing friction with the wheel hub, and preventing loosening after installation.

Passivation: For bolts that don’t require a colored appearance, nitric acid passivation can be used. This involves immersing the bolts in a 20%-30% nitric acid solution for 10-15 minutes to form a denser oxide film on the surface. This passivation treatment further improves the bolts’ salt spray resistance, allowing them to withstand over 1,000 hours in a salt spray test (neutral salt spray, GB/T 10125-2021), far exceeding the approximately 200 hours for steel bolts.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts