ICCP MMO Linear Anodes

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

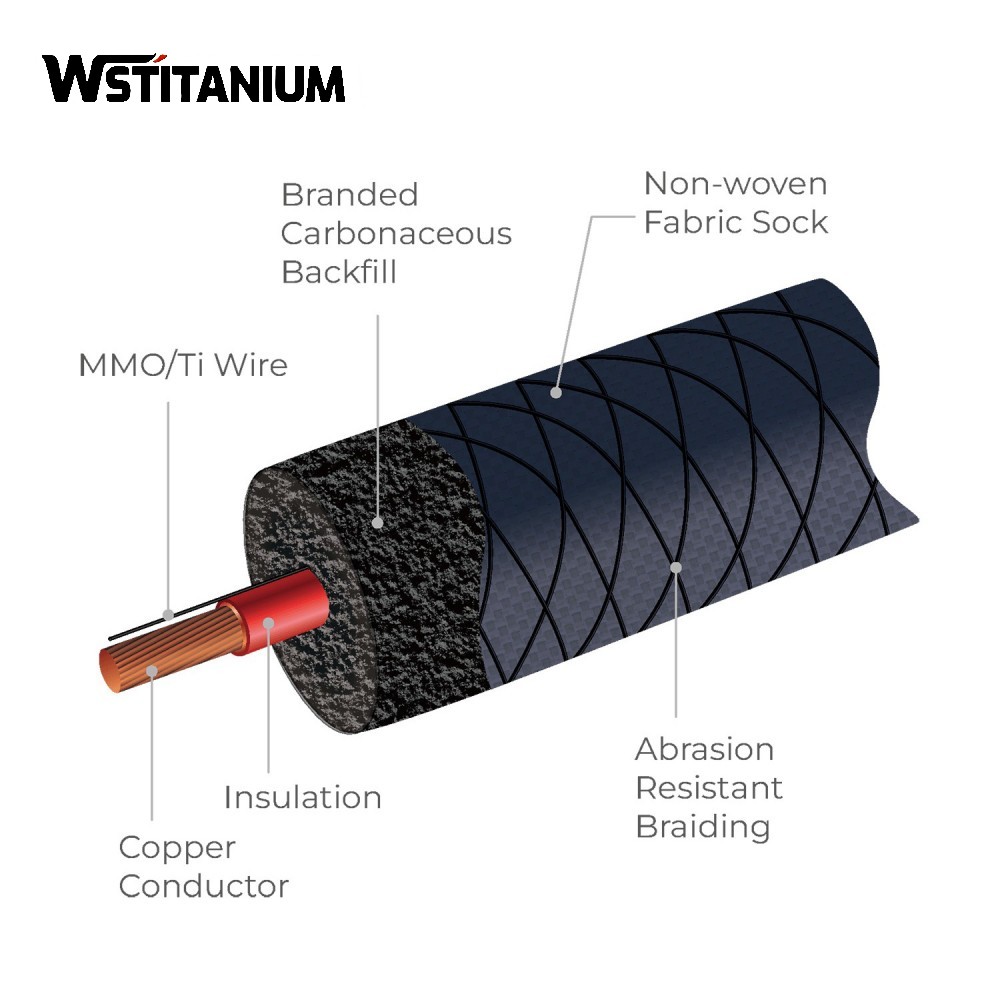

MMO linear anodes (flexible anodes) are ideal for applications requiring low-current, uniformly distributed cathodic protection systems. The anode core is a high-quality titanium wire (Gr1 or Gr2) coated with an Ir-Ta mixed metal oxide catalyst. The titanium wire is pre-wound in a porous non-woven fabric “sleeve.” The sleeve is filled with highly conductive calcined petroleum coke powder, enhancing the anode’s abrasion resistance and damage resistance. The power supply cable is 6 AWG stranded copper wire. The insulation layer uses high molecular weight polyethylene (HMWPE).

| Category | Core Content | Key Indicators / Core Information |

| Components | Core Conductor | Material: Gr1/Gr2 pure titanium (wire/tape); Diameter: 0.8-2.5mm (wire), 3-10mm (tape width); Surface roughening treatment. |

| MMO Coating | System: IrO₂-Ta₂O₅ (abrasion-resistant environment), RuO₂-TiO₂ (high catalytic activity); Thickness: 20-50μm; Consumption rate ≤ 0.01g/A·a | |

| Insulation Sheath | Main material: HMWPE; Breakdown voltage ≥20kV/mm; Temperature resistance: -40℃~80℃ (regular), ≤120℃ (high-temperature modified) | |

| Technical Parameters | Connection Components | Material: Titanium alloy (silver-plated/gold-plated); Connection method: Crimping/welding/threading; Contact resistance ≤5mΩ |

| Electrical Performance | Working current density: 10-50A/m² (maximum 100A/m²); Polarization rate ≤100mV/A·m; Grounding resistance: 1-10Ω·m | |

| Mechanical Performance | Tensile strength ≥300MPa; Minimum bending radius ≤50mm; Sheath abrasion loss ≤0.5g (1000 revolutions) | |

| Dimension Specifications | Diameter: 1.0-3.0mm (circular), 3-10mm (tape width); Standard length: 50/100/200m (customizable up to 500m) | |

| Manufacturing Technology | Key Processes | Conductor pretreatment: Pickling + activation; Coating preparation: Thermal decomposition (3-5 times repeated coating); Sheath forming: Extrusion molding; Finished product inspection: Comprehensive electrical/mechanical/insulation testing |

| Main Applications | Buried Pipeline | Laying method: Single/double parallel laying (0.5-1.5m from pipeline); Current demand: 10-20A/km; Backfill material: Graphite powder + bentonite |

| Tank Bottom Plate | Laying method: Circular + radial/mesh; Current demand: 20-30A/100m²; Backfill material: Coke powder | |

| Marine Engineering | Adaptable medium: Seawater/intertidal zone/submarine sediment; Coating selection: Iridium series; Sheath: Modified HDPE/fluoroplastic | |

| Industrial Equipment | Adaptable medium: Strong acid/strong alkali/high-chlorine wastewater; Installation method: Suspended/built-in/wall-mounted |

In the field of metal corrosion protection, cathodic protection technology, due to its high efficiency and durability, has become a core solution for addressing corrosion problems of metal structures in complex environments such as soil, seawater, and industrial media. Impressed current cathodic protection systems, as an important branch of cathodic protection technology, provide a continuous protective current to the protected metal structure through an external power source, forming a stable cathodic polarization zone on its surface, thereby inhibiting corrosion reactions. In this system, the anode, as the key component for current output, directly determines the stability of the protective effect, its service life, and the engineering economy.

MMO (Mixed Metal Oxide) linear anodes are the core anode type in impressed current cathodic protection systems. With their excellent electrocatalytic activity, extremely low loss rate, good chemical stability, and flexible installation methods, they have gradually replaced traditional graphite anodes, high-silicon cast iron anodes, etc. MMO linear anodes have become the preferred anode material for metal corrosion protection projects such as long-distance pipelines, large storage tank bottom plates, and underground structures. Compared to other anodes, MMO linear anodes not only maintain stable current output in complex geological environments but also effectively reduce the footprint of the anode bed, lowering construction difficulty and subsequent maintenance costs. They are particularly suitable for critical infrastructure with high corrosion resistance requirements and long service lives.

1. Core Conductor.

The core conductor is the current carrier in the MMO linear anode. Its function is to uniformly conduct the current supplied by the external power source to the MMO coating surface, while also providing mechanical support for the coating. The performance of the core conductor directly affects the conductivity, mechanical strength, and service life of the anode; therefore, strict requirements are placed on material selection and structural design.

Currently, titanium wire or titanium strip is mainly used as the core conductor for MMO linear anodes. Commonly used materials are Gr1 or Gr2. Titanium is the preferred core conductor primarily due to its three advantages: First, excellent corrosion resistance; titanium can form a dense oxide film in environments such as soil, seawater, and acidic or alkaline media, preventing itself from corroding. Second, good conductivity; although titanium’s conductivity is not as high as copper or aluminum, it maintains stable conductivity during long-term service and has excellent adhesion to the MMO coating. Third, high strength and flexibility; titanium wire/strip can be processed into different diameters and lengths according to requirements, facilitating bending and laying, while also withstanding mechanical stress during construction and service.

The structural design of the core conductor must balance conductivity uniformity and mechanical stability. For linear anodes, the core conductor is typically made of round wire (1.0-3.0 mm in diameter) or flat strip (3-10 mm wide, 0.5-1.5 mm thick). Some products undergo surface roughening treatment (such as sandblasting or acid etching) to enhance adhesion to the MMO coating and prevent coating peeling. Furthermore, the ends of the core conductor undergo special treatment (such as tin plating or crimping terminals) to ensure reliable connection to external cables and reduce contact resistance.

2. MMO Coating

The MMO coating is the core functional layer of the impressed current linear anode, playing a crucial role in converting electrical energy into chemical energy and achieving uniform current release. Its performance is a key factor determining the overall quality of the anode. The MMO coating is made by mixing noble metal oxides (such as IrO₂, RuO₂) and transition metal oxides (such as TiO₂, Ta₂O₅) in a specific ratio, and coated onto the surface of the titanium alloy core conductor using a special technique to form a uniform and dense functional film.

Coating Composition Design: The composition ratio of the MMO coating directly affects its electrocatalytic activity, stability, and lifespan. Currently, the mainstream coating systems are “iridium-based” and “ruthenium-based.” Iridium-based coatings (such as IrO₂-Ta₂O₅) exhibit higher chemical stability and resistance to degradation, making them suitable for harsh environments such as seawater and strong acids. Ruthenium-based coatings (such as RuO₂-TiO₂) possess superior electrocatalytic activity and lower polarization, making them suitable for conventional environments such as soil and freshwater. Furthermore, some MMO products incorporate precious metals such as Pd and Pt, or oxides such as SnO₂ and Sb₂O₅, to further optimize the overall performance of the coating.

Coating Structural Characteristics: MMO coatings have a porous structure, with a porosity typically between 20% and 40%. This structure not only increases the contact area between the coating and the electrolyte, improving current output efficiency, but also promotes the removal of reaction products (such as oxygen and chlorine), reducing polarization. The coating thickness is generally controlled between 20-50 μm. Too thin a coating leads to easy wear and a shortened lifespan, while too thick a coating increases contact resistance and affects conductivity.

Core Function: The core function of the MMO coating is to catalyze the oxidation reaction of the electrolyte under energized conditions (e.g., the oxidation reaction of water in soil: 2H₂O – 4e⁻ → O₂↑ + 4H⁺), achieving stable current release. Compared to traditional anode coatings, the MMO coating has an extremely low consumption rate (typically less than 0.01 g/A・a), which is almost negligible. Therefore, the anode’s lifespan is mainly determined by the lifespan of the core conductor and the insulating sheath.

3. Insulating Sheath

The insulating sheath is the protective layer of the MMO linear anode. Its main function is to prevent direct contact between the anode and the protected metal structure, causing a short circuit, while protecting the MMO coating and core conductor from mechanical damage, chemical corrosion, and contamination from soil impurities. The performance of the insulating sheath directly affects the anode’s installation safety and service stability. The selection of materials and structural design must be specifically optimized based on the application environment (such as soil type, temperature, humidity, and chemical media).

Commonly used insulating sheath materials include high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), and polyvinyl chloride (PVC). HDPE is the most widely used material due to its excellent corrosion resistance, abrasion resistance, aging resistance, and mechanical strength. Modified polyethylene or fluoroplastics (such as PTFE) are used as insulating sheath materials in some special environments (such as high temperature, strong acid and alkali media).

The structural design of the insulating sheath must meet the following requirements: First, excellent insulation performance, with a breakdown voltage of not less than 20kV/mm, ensuring no leakage current occurs under the rated operating voltage; second, high mechanical strength, able to withstand dragging, squeezing, and soil stress during construction, preventing sheath breakage; third, good flexibility, facilitating anode bending and laying, adapting to complex construction paths; and fourth, strong compatibility with the core coating, not reacting chemically with the MMO coating, and ensuring strong adhesion. In addition, the insulating sheath is usually designed in a corrugated or smooth shape. The corrugated structure enhances the sheath’s tensile and bending resistance, while the smooth structure facilitates the anode’s installation in the soil.

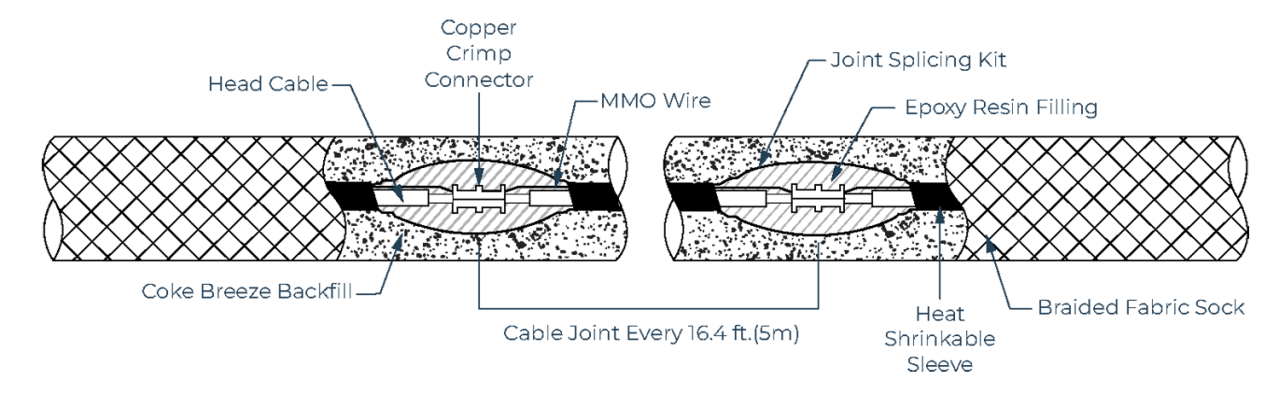

4. Connecting Components

Connecting components are key components for connecting the MMO linear anode to the external power supply and between the anode and the mains conductor. Their performance directly affects the conductivity continuity and stability of the entire cathodic protection system. The core requirements for connecting components are low contact resistance, strong connection, and high corrosion resistance.

Anode Connector: Used to connect multiple MMO linear anode segments, typically made of titanium alloy (the same material as the core conductor). The surface is silver-plated or gold-plated to reduce contact resistance. The structural design of the anode connector must ensure a tight fit with the anode core conductor. Common connection methods include crimping, welding, and threading.

Cable Connector: Used to connect the MMO linear anode to the external power cable, typically composed of titanium alloy terminals, an insulating sealing sleeve, and a corrosion-resistant protective sleeve. After the terminal block is connected to the anode core conductor, it must be sealed with an insulating sleeve to prevent moisture and electrolyte from entering and causing corrosion. An external anti-corrosion protective sleeve is then added to further enhance the protective effect. The insulation performance of the cable joint must be consistent with the anode insulating sleeve to ensure the overall insulation reliability.

5. Auxiliary Components

Auxiliary components are supporting parts for the installation and operation of the MMO linear anode system. Although they do not directly participate in current output, they have a significant impact on the system’s installation efficiency, operational stability, and maintenance convenience. They mainly include the following categories:

Backfill Material: Used to fill the soil around the anode. Its function is to reduce the anode grounding resistance, promote uniform current distribution, and protect the anode from mechanical damage from sharp impurities in the soil. Commonly used backfill materials are graphite powder, coke powder, or mixed conductive materials. The backfill material has good conductivity, strong chemical stability, and does not react with the anode.

Fixing Brackets: Used to fix the MMO linear anode in a predetermined position (such as below the tank bottom plate, on both sides of the pipeline) to prevent the anode from shifting during construction or service. Fixing brackets are usually made of corrosion-resistant materials (such as plastic and stainless steel).

Detection terminals: Used for on-site monitoring of the anode’s operating status, including parameters such as current output and voltage distribution, facilitating timely detection of system faults. Detection terminals are typically installed at anode connection points or critical nodes and are designed to be waterproof and corrosion-resistant.

Related products

-

Impressed Current Cathodic Protection

ICCP MMO Flexible Anode

-

Impressed Current Cathodic Protection

ICCP MMO Tubular Anode