Iridium Tantalum Titanium Anode

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Iridium-tantalum-titanium anodes are based on pure titanium substrate coated with a composite oxide of iridium and tantalum. The high strength and toughness of titanium are perfectly combined with the excellent conductivity and corrosion resistance of iridium and the stability of tantalum.With its three core advantages of long life, high activity, and low energy consumption, iridium-tantalum-titanium anodes are rapidly replacing traditional electrodes and becoming the “standard configuration” in the electrolysis industry. They are also continuously expanding into emerging fields such as new energy and environmental protection, driving the global industrial transformation towards greener and more efficient manufacturing.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂),Tantalum Oxide (Ta₂O₅) |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 85 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of Iridium-Tantalum-Titanium Anodes

The specifications of iridium-tantalum-titanium anodes are not limited to single-dimensional parameters, but rather encompass a comprehensive system of indicators encompassing three key categories: substrate dimensions, coating parameters, and electrochemical performance.

(I) Dimensions and Specifications

The titanium substrate, as the supporting structure of the anode, must precisely match the dimensions of the customer’s electrolytic cell, reactor, and other equipment. Mainstream specifications in the industry are categorized as flat, tubular, and mesh.

Plate anodes: Primarily used in applications with large cell areas, such as copper electrolysis and electroplating, common dimensions are 500-2000mm in length, 300-1000mm in width, and 2-5mm in substrate thickness. (Thinner thicknesses can lead to deformation, while thicker thicknesses increase cost and energy consumption.) For specialized applications (such as small experimental equipment), smaller sizes (e.g., 100mm x 100mm) can be customized. Large industrial cells can be spliced together to achieve extra-large dimensions exceeding 2000mm.

Tubular anodes: Suitable for applications such as water treatment and hydrogen production from water electrolysis. They typically have an outer diameter of 10-50mm, a length of 500-3000mm, and a wall thickness of 1.5-3mm. To improve electrolyte flow, some tubular anodes feature circular holes with a diameter of 2-5mm (hole spacing of 20-50mm).

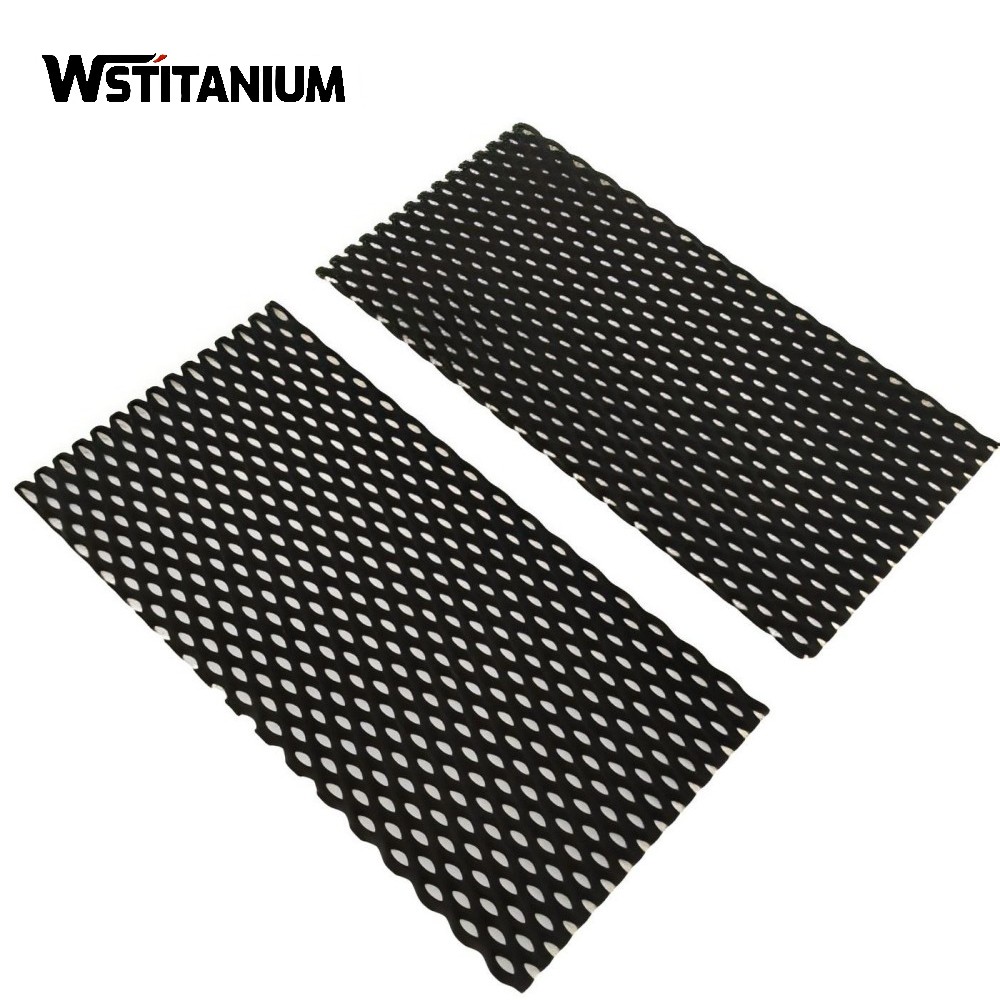

Mesh anodes: Commonly used in the electroplating industry, they utilize a mesh structure to achieve uniform current distribution. Common mesh sizes range from 5mm×5mm to 20mm×20mm (larger mesh sizes can lead to current concentration, while smaller mesh sizes can hinder electrolyte flow). The mesh wire diameter is 1-2mm, and the overall size can be customized to suit the production line width (typically 1000-3000mm).

(II) Core Coating Specifications

The coating is the core performance element of the iridium-tantalum-titanium anode. Its specifications primarily include composition ratio, thickness, and grain size. Different parameters correspond to different application requirements:

Coating Composition Ratio: The core components are IrO₂ (iridium oxide) and Ta₂O₅ (tantalum oxide). The ratio of these two components needs to be adjusted based on the application. For example, in high-activity applications such as water electrolysis for hydrogen production and chromium plating, the IrO₂ ratio is typically 80%-90% (a higher iridium content indicates stronger catalytic activity). In applications requiring high corrosion resistance, such as those using chlorine-containing electrolytes (e.g., the chlor-alkali industry and chlorine-containing wastewater treatment), the Ta₂O₅ ratio is increased to 20%-30% (a higher tantalum content indicates better resistance to chlorine corrosion). For general-purpose applications (e.g., general electroplating and electrolytic refining), a balanced ratio of IrO₂:Ta₂O₅ = 7:3 is used.

Coating Thickness: Typical thicknesses are 50-100μm, and the thickness must be tailored to the service life and current density. For water treatment applications with low current densities (e.g., <500A/m²), a coating thickness of 50-60μm can achieve a service life of 1-2 years. For copper electrolysis and water electrolysis applications with high current densities (e.g., >1000A/m²), the coating thickness should be increased to 80-100μm to prevent rapid coating consumption and anode failure.

Grain Size: Coating grain size is typically 50-200nm. Nanoscale grains (50-100nm) increase specific surface area (by more than 30% compared to traditional micron-sized grains) and enhance catalytic activity, making them suitable for applications requiring high efficiency, such as water electrolysis for hydrogen production and new energy material preparation. Grain sizes of 100-200nm prioritize stability and are suitable for long-term operation, such as in the chlor-alkali industry.

(III) Electrochemical Performance

Electrochemical performance is crucial to the stable operation of anodes. Clear industry standards exist, and these requirements form the core basis of factory testing:

Oxygen evolution overpotential: In a 1 mol/L H₂SO₄ solution at a current density of 1000 A/m², the oxygen evolution overpotential must be ≤1.5V (the lower the overpotential, the lower the electrolysis energy consumption). High-quality products (such as Wstitanium) can maintain this value below 1.4V, saving up to 5%-10% in annual electricity costs per cell.

Lifespan stability: ≥3 years for the chlor-alkali industry, ≥2 years for electrolytic copper, and ≥1 year for water treatment. Testing is verified through a 1000-hour constant current test, during which potential fluctuations must be ≤50mV. (Excessive potential fluctuations indicate coating instability and potential failure.)

Impurity dissolution: After immersion in a 1 mol/L H₂SO₄ solution at 25°C for 24 hours, the amount of Ir and Ta dissolved in the coating must be ≤0.1 mg/L to prevent impurities from contaminating the electrolyte. (For example, impurities in electroplating scenarios can cause pinholes in the plating layer, and impurities in pharmaceutical wastewater treatment can affect water quality.)

Advantages of Wstitanium

Traditional iridium-tantalum-titanium anode coatings utilize a uniform composition design. Under high current density and highly corrosive environments, the coating surface is susceptible to failure due to rapid depletion of active components. Wstitanium’s developed gradient coating technology achieves a dual improvement in both lifespan and activity:

Gradient Composition Design

The coating is divided into three layers from the substrate to the surface: a bottom layer (iridium: tantalum = 5:5), which bonds strongly to the titanium substrate and acts as a “transitional support.” A middle layer (iridium: tantalum = 7:3), which balances corrosion resistance and conductivity. A surface layer (iridium: tantalum = 9:1), with a high iridium content and strong catalytic activity. This gradient design prevents rapid depletion of active components in the surface layer while ensuring overall coating stability.

Nanocrystalline Coating Structure

By controlling the sintering temperature and heating rate, Wstitanium achieves a nanocrystalline structure by controlling the IrO₂-Ta₂O₅ grain size within the coating to 50-100nm. Nanocrystals not only increase the coating’s specific surface area (over 30% higher than traditional coatings), enhancing catalytic activity and crack resistance, but also extend the anode life by 50%-100% (in the electrolytic copper industry, traditional anodes have a lifespan of approximately 1-2 years, while Wstitanium products can reach 3-5 years).

Customization Capabilities

The requirements for iridium-tantalum-titanium anodes vary significantly across industries and processes (for example, water electrolysis for hydrogen production requires high oxygen evolution activity, electroplating requires low cell voltage, and water treatment requires resistance to chlorine corrosion). Wstitanium has established a customized R&D-production system, enabling it to provide tailored solutions for specific scenarios.

Quality Control

Wstitanium has established a full-process quality traceability system. Six key inspection points are implemented during manufacturing: incoming raw materials inspection, substrate pretreatment inspection, coating solution preparation inspection, post-coating drying inspection, post-sintering coating inspection, and finished product electrochemical performance inspection). To verify the life of iridium-tantalum-titanium anodes, Wstitanium built an “accelerated aging test platform” – conducting 1000-hour accelerated tests on anodes in an electrolyte with a current density higher than actual operating conditions (such as 2000A/m²) and a higher temperature (such as 80°C).

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt