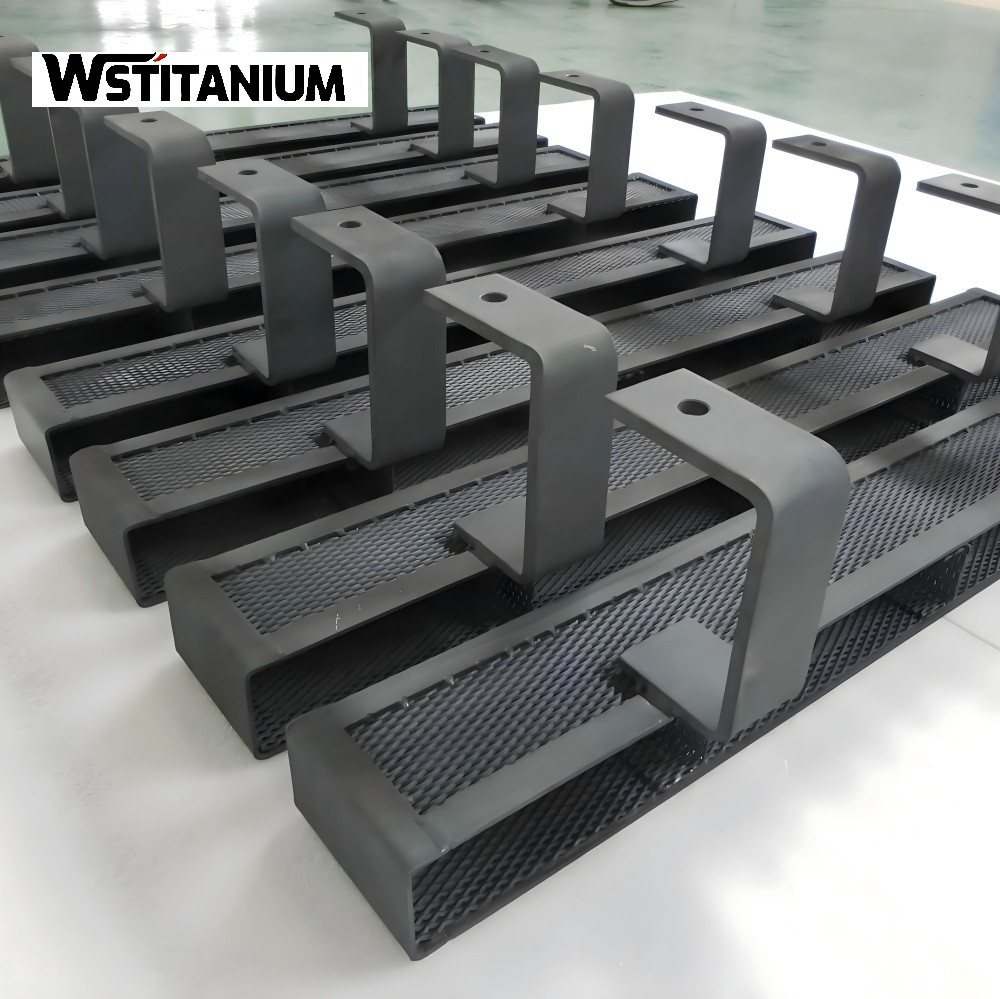

MMO Titanium Anode Basket

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

MMO titanium anode basket is a key form of titanium-based metal oxide-coated electrode (MMO). It utilizes a pure titanium (Gr1/Gr2) matrix, forming a mesh basket structure. Coatings of ruthenium, iridium, and tantalum are applied to the surface, creating a core component that combines structural support with electrochemical activity.

MMO titanium anode basket’s mesh design creates a three-dimensional reaction space, increasing its surface area by 3-5 times compared to flat electrodes. Furthermore, the coating technology improves corrosion resistance by over 10 times while reducing overpotential by 20%-30%. Furthermore, the matrix can be reused 3-5 times, reducing lifecycle costs by over 40%. Today, the MMO titanium anode basket has become an indispensable core equipment in the chlor-alkali, electroplating, and environmental protection industries.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Manufacturing MMO Titanium Anode Baskets

The titanium substrate is essential for ensuring the basket’s structural strength and corrosion resistance. Pure titanium (Gr1/Gr1) with a purity of ≥99.5% is required. Depending on the application, the titanium thickness must be precisely controlled: 0.8-1.2mm titanium plate is used for conventional electroplating. Heavy-duty electrolysis requires 1.5-2.0mm to withstand the impact of high current densities.

Laser Cutting

A CNC laser cutting machine machining the titanium into mesh and frames of pre-defined dimensions, with an accuracy of ±0.5mm. Subsequently, the basket is sandblasted using 80-120 mesh white corundum sand to create a uniformly rough surface, enhancing coating adhesion. Finally, it undergoes pickling and passivation, boiling in a 5%-10% oxalic acid solution for 10-15 minutes to thoroughly remove the surface oxide layer and oil contamination, creating an active surface.

Welding

The basket’s main body is constructed from a porous woven titanium mesh. The porosity is controlled between 60% and 80%, and the mesh size is selected based on the electrolyte characteristics, with a diamond or circular pattern ranging from 6×3mm to 12.5×4.5mm. Welding is a key technology for the basket’s structural integrity and is performed using TIG welding. The spacing between weld points is controlled at 15-20mm.

Coating

The coating is the core of the MMO titanium anode basket, determining its electrochemical performance and service life. Titanium anodes are primarily produced using two techniques: brush coating and sintering, and spray coating and sintering. The former is suitable for applications requiring high precision, while the latter is more suitable for large-scale production.

Coating Materials: The chlorine evolution system uses a RuO₂-IrO₂ composite oxide with a chlorine evolution overpotential of ≤1.36V (vs. SHE); the oxygen evolution system uses an IrO₂-Ta₂O₅ mixed oxide, suitable for sulfate systems. The coating thickness is controlled at 15-20μm.

Sintering: Pre-bake in a 120°C oven for 10 minutes, followed by sintering in a muffle furnace at 450-550°C for 30-40 minutes to convert the salts into oxides and form a metallurgical bond with the titanium substrate. This process is repeated 8-12 times, ultimately resulting in a dense coating 10-100μm thick.

Quality Inspection

Coating thickness is measured using an eddy current thickness gauge, with an error of no more than ±0.5μm at any point. Electrical performance testing is conducted under simulated operating conditions to ensure that overpotential and current efficiency meet design standards. For example, chlor-alkali products must meet current efficiency ≥94%. The coating exhibits no flaking after 72 hours of immersion in acidic or alkaline media with a pH of 0-14. The corrosion rate is less than 0.5μm/year after 100 hours of electrolysis in a 300g/L high-chloride solution. Samples from each batch are retained for 5,000 hours of continuous operation testing to ensure the actual service life meets the promised standards.

Wstitanium’s Advantages

As a provider of MMO titanium anode solutions, Wstitanium has developed three core competitive advantages: technological innovation, quality control, and service capabilities.

Coating Technology

Wstitanium pioneered the use of nano-particle dispersion technology to produce coatings, controlling the particle size of precious metal oxides to 50-100nm. This increases the coating’s surface area by 40% and significantly enhances catalytic activity. The coating exhibits no risk of flaking even at a high current density of 10,000A/m². The RuO₂-TiO₂ gradient coating, specifically designed for the chlor-alkali industry, achieves chlorine purity of 99.98%.

Customized Services

Wstitanium provides comprehensive customization services, including basket size optimization, mesh parameter adjustment, and coating formulation customization.

Applications of MMO Titanium Anode Baskets

Due to their core advantages of dimensional stability, low energy consumption, and corrosion resistance, MMO titanium anode baskets have been widely used in multiple industrial sectors, becoming a key piece of equipment driving technological advancements in the industry.

(1) Chlor-alkali Industry

The chlor-alkali industry is a traditional area of strength for MMO titanium anode baskets, primarily used for the chlorine evolution reaction in ion-exchange membrane caustic soda production. Anode baskets with a RuO₂-TiO₂ gradient coating can keep the chlorine evolution overpotential below 1.36V, increasing current efficiency to over 94%. They can withstand Cl⁻ concentrations exceeding 300g/L and have a service life of over five years.

(2) Electroplating

MMO titanium anode baskets fulfill the dual functions of providing uniform current and stabilizing electrolyte concentration. An IrO₂-SnO₂ composite coating is used for acidic copper plating, while a RuO₂-IrO₂ coating is used for alkaline zinc plating. Electroplating yields have increased from 82% to 97%, and single-line production capacity has increased by 40%. They are compliant with RoHS and other standards.

(3) Water Treatment

MMO titanium anode baskets have become core components of electrolytic oxidation technology, widely used in applications such as printing and dyeing wastewater, chemical wastewater, and swimming pool disinfection. In dyeing wastewater treatment, their PbO₂-MnO₂ doped coating, combined with a three-dimensional electrode system, efficiently generates hydroxyl radicals, achieving a COD removal rate of 85% and a color removal rate exceeding 90%.

(4) Hydrometallurgy

In hydrometallurgy, MMO titanium anode baskets are primarily used for the electrolytic extraction and purification of metals such as copper, zinc, and nickel. For copper electrolysis in sulfuric acid systems, anode baskets with an IrO₂-SnO₂ composite coating can reduce the oxygen evolution overpotential, lower electrolysis energy consumption by 20%, and increase cathode copper purity to 99.99%.

Choosing the right MMO titanium anode basket requires comprehensive consideration of three key factors: First, clarify the application scenario, such as the electrolysis system (chlorine/oxygen evolution), current density, and dielectric environment, to determine the coating formula and basket structure; second, evaluate the supplier’s technical strength, giving priority to brands with customization capabilities and a full-process quality control system, such as Wstitanium; third, focus on the entire life cycle cost, rather than just considering the initial purchase cost. It is necessary to comprehensively calculate its energy-saving benefits, service life, and maintenance costs to maximize long-term economic benefits.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts