MMO Titanium Anode Distributor

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Wstitanium has become a core distributor of MMO titanium anodes in China, providing a full range of customized electrode solutions to customers worldwide. Its titanium anodes include ruthenium, iridium, and platinum-based materials, along with specialized coatings, in six formats: mesh, tube, plate, and wire. These MMO titanium anodes are suitable for applications in the chlor-alkali, environmental protection, electroplating, and new energy industries.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | 5 years |

Core Advantages

Wstitanium is located in Baoji, China’s largest titanium production base. The procurement cost of pure titanium, used as the raw material for titanium anode substrates, is 12%-18% lower than the industry average, and the substrate purity consistently remains above 99.6%, providing a fundamental guarantee for coating adhesion.

Quick Response

Leveraging the synergy of the industrial cluster, we achieve localized production of the entire process, from laser cutting, surface treatment, to coating preparation. Standard MMO anode delivery cycles are shortened to 7-10 days, while customized titanium anodes are delivered within 20 days, significantly lower than the industry average of 30 days.

Production

Coating thickness control accuracy reaches ±0.5μm, porosity is precisely adjusted between 35% and 45%, and coating adhesion meets ASTM D3359 Class 4B standards as tested by the cross-cut method.

Quality Inspection

Equipped with cyclic voltammeters and accelerated life testing systems, each batch of titanium anodes undergoes electrochemical performance testing to ensure current efficiency ≥95%, polarization voltage ≤200mV, and an accelerated life of over 8,000 hours at 2A/cm².

Customized Services

To meet the needs of different industries, Wstitanium’s professional technical team can customize coating formulations and anode morphologies based on your provided parameters, including electrolyte composition, current density, temperature, and pressure. For example, we develop specialized tantalum-doped coatings for high-fluorine environments, increasing the fluorine concentration tolerance to over 50ppm. Coating materials are a key factor in determining the performance of MMO titanium anodes. Based on different electrochemical reaction characteristics, Wstitanium has developed three types of coating systems, covering over 95% of industrial applications:

1. Ruthenium Coatings

Based on RuO₂-IrO₂ and RuO₂-TiO₂ composite oxides, they focus on optimizing chlorine extraction performance. The chlorine evolution overpotential is ≤1.36V (vs. SHE), making it particularly suitable for high-chloride environments. This coating remains stable in Cl⁻ concentrations above 300g/L, with an annual corrosion rate of less than 0.01mm. It is a specialized coating system for the chlor-alkali industry. Field tests at a large chlor-alkali plant have shown that the use of this coated anode increased chlorine purity from 99.5% to 99.98%, with a current efficiency of 94%, achieving mercury-free production.

2. Iridium Coating

Mainly includes two mixed oxide formulations: IrO₂-Ta₂O₅ and IrO₂-SnO₂. These coatings focus on oxygen evolution reaction efficiency. The oxygen evolution potential can be controlled below 1.40V, with a polarizability of ≤40mV. Among them, the IrO₂-Ta₂O₅ coating offers exceptional corrosion resistance and stable operation within a pH range of 0-14. It is suitable for sulfate electrolysis and high-potential electrolytic hydrogen production, with a service life exceeding five years. The IrO₂-SnO₂ coating excels in hydrometallurgy, particularly suited for the electrolytic extraction of metals such as copper and zinc.

3. Special Functional Coatings

Two types of specialized coatings have been developed for high-end precision applications: a platinum-group metal modified layer, doped with nano-sized platinum particles, achieves coating thickness uniformity of ±3%, meeting the precision electroplating requirements of 5G communication devices and high-end watches. The PbO₂-MnO₂-doped coating is specifically designed for treating refractory organic matter. In dyeing and printing wastewater treatment, it can achieve a COD removal rate of 85% and a color removal rate exceeding 90%. Furthermore, for aluminum foil electroplating, the custom-developed iridium-tantalum coating can operate stably in ammonium adipate and ammonium citrate media for 9-18 months, achieving a weight loss of ≤0.006 mg/s⁻¹.

MMO Titanium Anode Shapes

Wstitanium offers six types of MMO titanium anodes, tailored to the equipment structure and space requirements of various industries. Full-size customization is available:

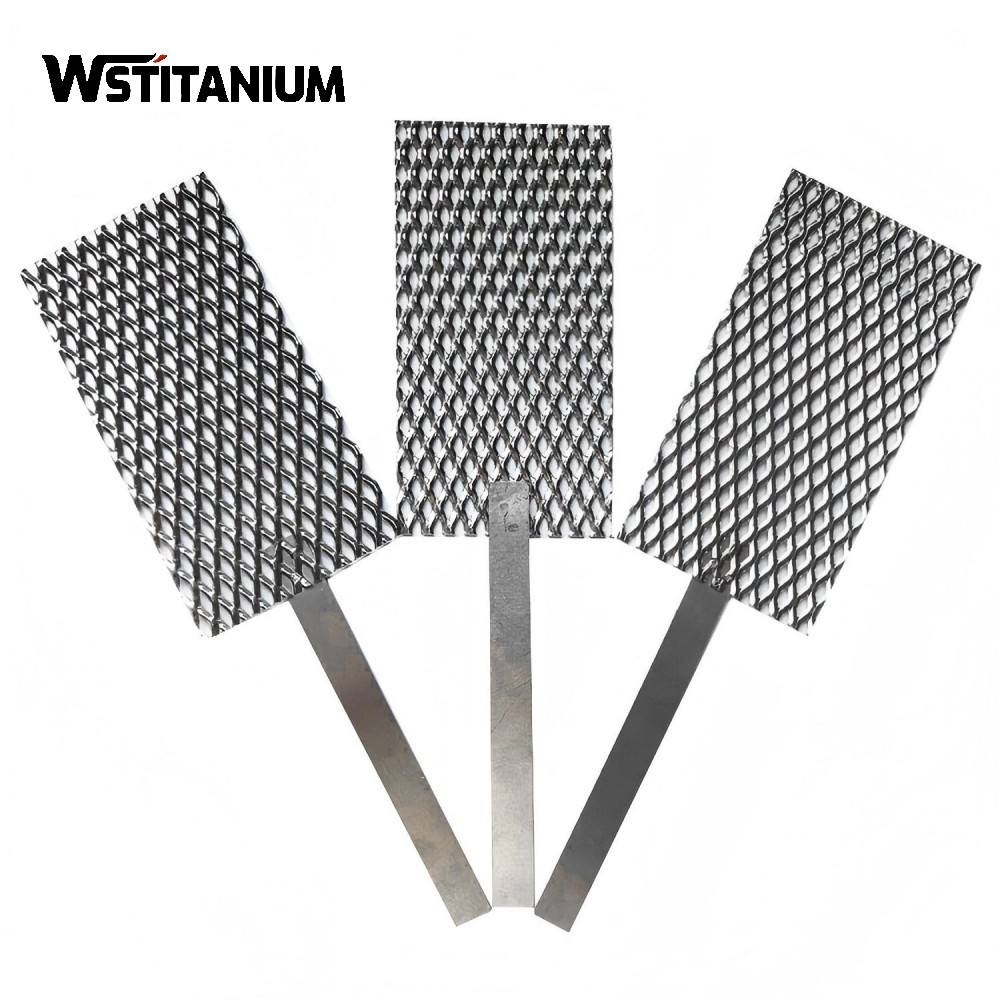

1. Mesh Anode

Woven from 3×50mm titanium ribbon, this anode features a mesh density of 50-200 mesh and a porosity of 60%-80%. Its surface area is 3-5 times higher than that of flat electrodes, making it particularly suitable for applications requiring efficient mass transfer. Standard sizes range from 500×1000mm to 2000×3000mm, and it can be spliced to suit the size of the electrolytic cell. For tank corrosion protection, mesh anodes laid at 3m intervals can increase edge protection coverage from 85% to 98%.

2. Tubular Anodes

Outer diameter specifications are 20-100mm, standard lengths are 1-3 meters, and can be customized up to 6 meters. Wall thicknesses are 3-5mm to ensure strength for deep well installation. Multiple anodes can be connected in series to form anode strings with dimensions of 219×4000mm, 219×6000mm, and other sizes, providing a protection radius of up to 150m.

3. Plate Anodes

Using 0.5-3mm thick Gr1-grade titanium plates, the surface is sandblasted to enhance coating adhesion. Standard sizes are 300×500mm and 500×800mm, and customizable cutting is possible. In the electroplating industry, plate anodes provide uniform current distribution, increasing the electroplating yield of mobile phone midframes from 82% to 97%.

4. Wire and Flexible Anodes

Wire anodes have a maximum diameter of 3mm. Flexible anodes utilize an 8mm PTFE encapsulation with a minimum bend radius of 50mm, allowing for flexible routing along equipment contours. In the cargo hold area of LNG carriers, flexible anode cables achieve a splash zone protection potential compliance rate exceeding 99%, increasing installation efficiency threefold compared to traditional plate anodes. Their unique connection design ensures that a single point breakage does not affect overall performance.

5. Rod Anodes

Diameters range from 8-20mm, and lengths range from 500-2000mm. They are primarily used in small electrolysis equipment and laboratory devices. In small water treatment equipment, rod anodes enable precise localized electrolysis and, when combined with a three-dimensional electrode system, improve pollutant removal efficiency.

6. Wire Anodes

Diameters range from 1-3mm. Made using a precision wire drawing process, they are suitable for high-density electrochemical devices. They are widely used in micro-electroplating and medical devices, enabling nanoscale coating control.

Application Industries

Wstitanium’s MMO titanium anodes are suitable for solutions in six major application areas.

1. Chlor-alkali Industry

Wstitanium offers ruthenium-coated mesh anodes and tubular anodes. Chlorine evolution overpotentials are as low as 1.36V, with current efficiencies consistently exceeding 95%. Cell voltage fluctuations are controlled within ±2%, completely eliminating the pulverization and contamination issues associated with traditional graphite anodes.

2. Water Treatment

For industrial wastewater and seawater desalination applications, we offer iridium- and PbO₂-doped coated anodes. Electrolysis systems constructed with mesh anodes can process 500,000 tons per day, achieving an algae removal rate of 98%. In the desalination industry, they can withstand Cl⁻ concentrations exceeding 300g/L and have a service life exceeding 20 years.

3. Electroplating

We offer platinum-group metal-modified coated anodes for precision electroplating and iridium-coated anodes for general electroplating. In the gold plating process for 5G communication devices, the coating thickness uniformity reaches ±3%, reducing the scrap rate by 80%. In the electroplating production line for automotive parts, the anode replacement cycle is extended from 6 months to 5 years.

4. Cathodic Protection

We offer a variety of anode forms, including tubular and flexible, to suit different corrosion protection scenarios. For tank corrosion protection, we use mesh anodes, achieving a stable protection potential of -850mV to -1100mV (CSE). For desert pipelines, we use deep-well anode arrays, reducing the driving voltage from the traditional 6.8V to 2.3V. For offshore platforms, we use flexible anodes, achieving a corrosion depth of less than 0.1mm over ten years.

5. New Energy Industry

For green hydrogen production, we provide high-iridium-content IrO₂-Ta₂O₅ coated anodes. When used with titanium-based PEM electrolyzers, they reduce hydrogen production energy consumption to 4.2kWh/Nm³, a 20% reduction compared to traditional alkaline electrolyzers.

6. Hydrometallurgy

For the electrolytic extraction of metals such as copper, zinc, and nickel, we provide IrO₂-SnO₂-coated anodes. These maintain a low polarization in acidic electrolytes, improving metal precipitation efficiency by 10%-15%. This improves the overall energy efficiency of the electrolytic cell by 25%, reducing the production cost of zinc by $50 per ton.

Related products

-

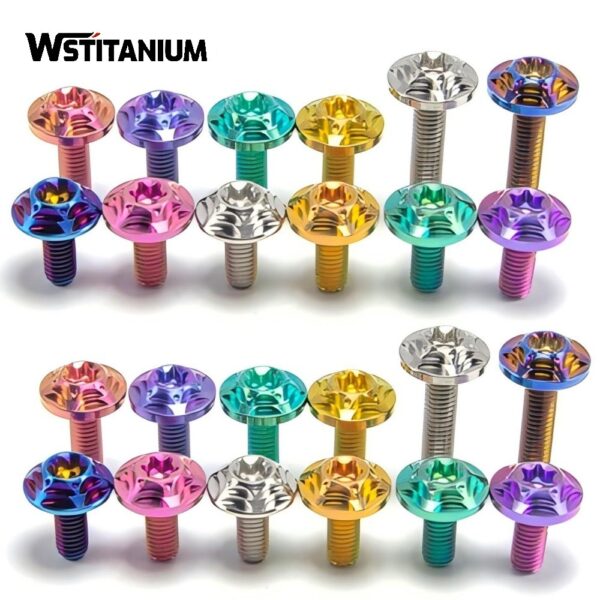

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Colored Bicycle Titanium Bolts