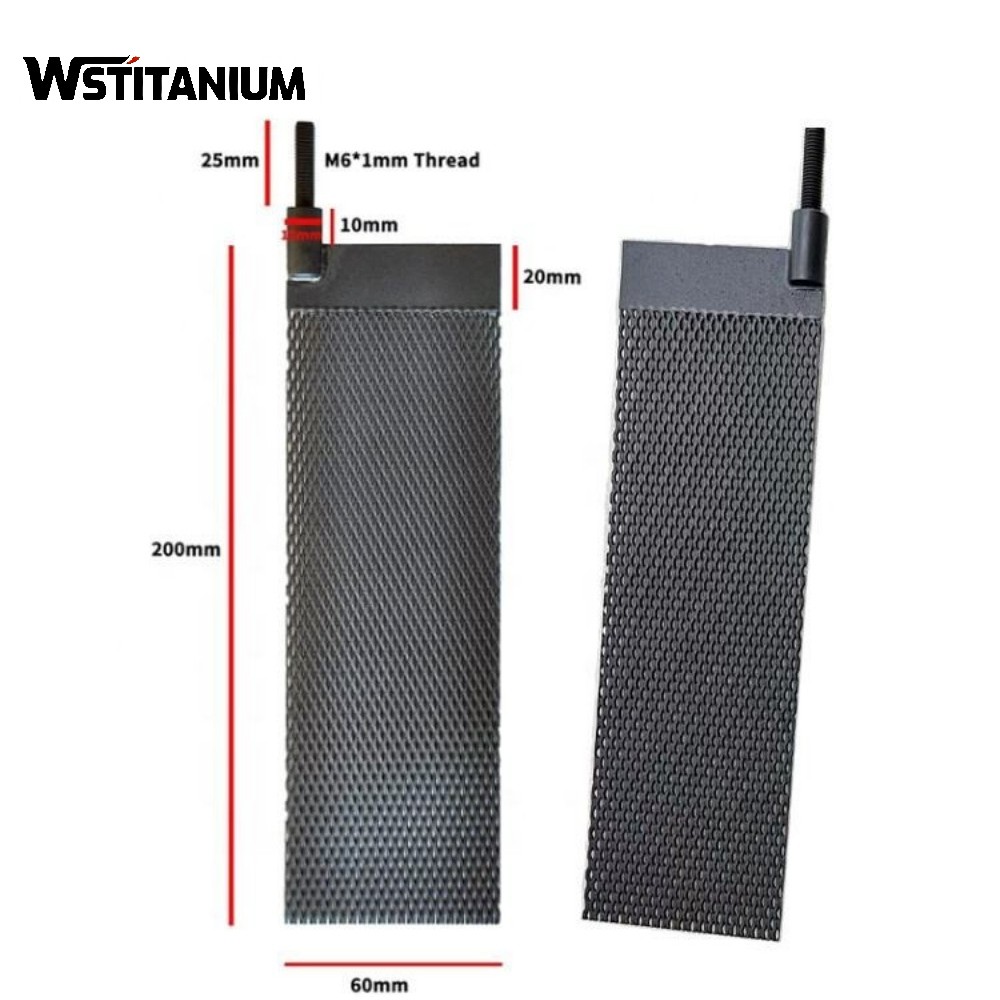

MMO Titanium Anode For Aniline

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Aniline compounds are important aromatic amine organic chemical raw materials, and their derivatives widely support the development of key industries such as pharmaceuticals, dyes, and pesticides. However, these compounds are highly toxic, difficult to biodegrade, and environmentally cumulative. Aniline-containing wastewater generated during production, storage, and transportation has become a major source of pollution threatening aquatic environmental safety.

Mixed metal oxide titanium anodes (MMO titanium anodes) offer breakthrough advantages in the electrochemical oxidation treatment of organic pollutants, leveraging the excellent corrosion resistance of their titanium substrate and the high catalytic activity of their precious metal oxide coating. By precisely controlling the electrochemical reaction, they achieve efficient degradation and even complete mineralization of aniline compounds, overcoming bottlenecks in traditional technologies.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Aniline Compound Pollution

Aniline compound pollution primarily stems from the discharge of aniline-containing wastewater, posing the greatest environmental risk. Approximately 15%-25% of aniline is lost as wastewater during diazotization and coupling reactions in dye synthesis, and during nitration and reduction in pharmaceuticals. Furthermore, leakage from containers during transportation and improper waste disposal can also cause soil and water contamination.

Biological Toxicity: Aniline can enter organisms through skin contact and inhalation, impairing the oxygen-carrying capacity of hemoglobin, leading to methemoglobinemia and causing permanent damage to organs such as the liver and kidneys. Experimental data show that the median lethal concentration (LC50) of aniline for fish is only 0.2-2.0 mg/L, making it an extremely toxic substance.

Environmental Persistence: Aniline has a stable molecular structure, with a half-life of several months to years in the natural environment. It is easily accumulated through the food chain, posing a potential threat to ecosystems and human health.

Difficulty in Degradation: High-concentration aniline wastewater (>100 mg/L) is highly inhibitory, inactivating microorganisms in biological treatment systems. Meanwhile, low-concentration wastewater is difficult to completely remove using conventional methods.

Complex Pollution Characteristics: Industrial wastewater often contains multiple pollutants, such as aniline and nitrobenzene, along with high salt concentrations, creating a complex pollution system characterized by “toxicity + high salt content,” further increasing the difficulty of treatment.

Working Principle of the MMO Titanium Anode

The MMO titanium anode degrades aniline compounds through electrocatalytic oxidation. This process integrates direct and indirect oxidation mechanisms, dynamically adjusting the degradation pathway based on pollutant concentration and reaction conditions, ultimately achieving harmless treatment of pollutants.

(I) Direct Oxidation

Direct oxidation involves the direct oxidation of aniline molecules on the anode surface through electron transfer. It is primarily suitable for treating high-concentration aniline wastewater.

Adsorption: Aniline molecules are adsorbed onto the MMO coating surface through electrostatic attraction and van der Waals forces, forming a stable adsorption layer that creates conditions for electron transfer.

Electron Transfer: Under the influence of the electric field, aniline molecules lose electrons and are oxidized to cationic free radicals. Subsequently, a series of reactions occur, including C-N bond cleavage and benzene ring opening.

Product Conversion: The oxidation products are gradually converted into intermediates such as p-benzoquinone and maleic acid, and ultimately partially converted into CO₂ and H₂O, leading to mineralization.

Kirk et al. experimentally confirmed that the degradation of aniline on the MMO anode surface primarily relies on this direct oxidation pathway, with an electron transfer efficiency exceeding 85%.

(II) Indirect Oxidation Mechanism

Indirect oxidation utilizes reactive oxidative species (ROS) generated by the anodic reaction to achieve aniline degradation, and is a dominant mechanism in low-concentration wastewater treatment.

Hydroxy radicals (H₂O or OH⁻) discharge on the anode surface to generate physically adsorbed ・OH, which has a redox potential as high as 2.8 V. This free radical can indiscriminately attack aniline molecules, initiating a chain oxidation reaction that ultimately completely mineralizes the aniline into inorganic products. This process, known as “electrochemical combustion,” produces few intermediates and achieves complete degradation.

Mediated Oxidation: In a chloride-containing electrolyte system, Cl⁻ is oxidized to Cl₂ at the anode, which further hydrolyzes to produce active chlorine species such as HClO/ClO⁻. Simultaneously, metal oxides such as Ru and Ir in the MMO coating form a reversible redox couple, cyclically converting to high-valent oxides during electrolysis, continuously oxidizing and degrading aniline.

(III) Reaction Control

The electrode oxidation theory proposed by Comninellis et al. reveals the reaction control characteristics of the MMO titanium anode: when non-stoichiometric high-valent oxides are formed at the anode, aniline undergoes selective “electrochemical conversion,” primarily to biodegradable intermediates. When the electrode reaches its highest valence state, “electrochemical combustion” occurs primarily through the formation of ・OH. This characteristic allows the MMO titanium anode to flexibly adapt to different treatment objectives (detoxification/recycling) by adjusting parameters such as voltage and current density.

In practical applications, when the wastewater contains Fe²⁺, the H₂O₂ generated at the cathode can form a Fenton system with Fe²⁺, forming a synergistic effect with anode oxidation, increasing the COD removal rate to more than 77.5% and the current efficiency to as high as 97.8%, showing a significant enhanced degradation effect.

Types of MMO Titanium Anodes for Aniline Compounds

Based on differences in coating composition and structural design, MMO titanium anodes suitable for aniline compound treatment are primarily divided into the following three categories. Each anode type has distinct characteristics in terms of catalytic activity and stability.

(I) Ruthenium MMO Titanium Anodes

RuO₂ is the primary active ingredient, supplemented with oxides such as TiO₂ to form a solid solution coating. The typical formulation is RuO₂-TiO₂ (molar ratio 1:1 to 1:4).

Ruthenium-based MMO titanium anodes exhibit excellent conductivity and chlorine evolution activity, with a chlorine evolution potential as low as 1.3 V. They can efficiently generate active chlorine species in chlorinated wastewater systems. Ruthenium-based MMO titanium anodes are suitable for treating high-salinity aniline wastewater, particularly those containing chloride salts, such as those in the dye industry. When treating aniline wastewater with a concentration of 200 mg/L, current efficiencies can reach 75%-85%, and COD removal rates exceed 60%.

(II) Iridium MMO Titanium Anodes

IrO₂ is used as the active component, combined with Ta₂O₅, TiO₂, and other materials to form a composite coating. The most common type is IrO₂-Ta₂O₅-TiO₂. Iridium-based MMO titanium anodes exhibit extremely high chemical stability and oxygen evolution activity, and are resistant to a wide pH range of 2-12. They have a strong ability to generate OH and high electrochemical combustion efficiency, enabling deep mineralization of aniline.

Iridium-based MMO titanium anodes are suitable for treating high-concentration, highly acidic aniline wastewater, such as wastewater from pharmaceutical intermediate production. One experiment demonstrated that using IrO₂-Ta₂O₅ anodes to treat 180 mg/L aniline wastewater resulted in an aniline removal rate of over 99% within 10 hours.

(3) Tin-Antimony MMO Titanium Anode

This anode uses SnO₂ as a matrix, Sb₂O₅ as a dopant, and rare earth elements (Ce, La, etc.) are added to optimize performance, resulting in the Ti/SnO₂-Sb₂O₅-RE anode. This tin-antimony-based MMO titanium anode has a high oxygen evolution potential (approximately 2.0 V ± 0.1 V) and efficiently generates OH. It is suitable for deep treatment of low-salt aniline wastewater and can achieve efficient mineralization in a chlorine-free system. Cerium-doped tin-antimony anodes achieve a 100% removal rate for similar aromatic compounds and a COD degradation rate of 97.7%.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts