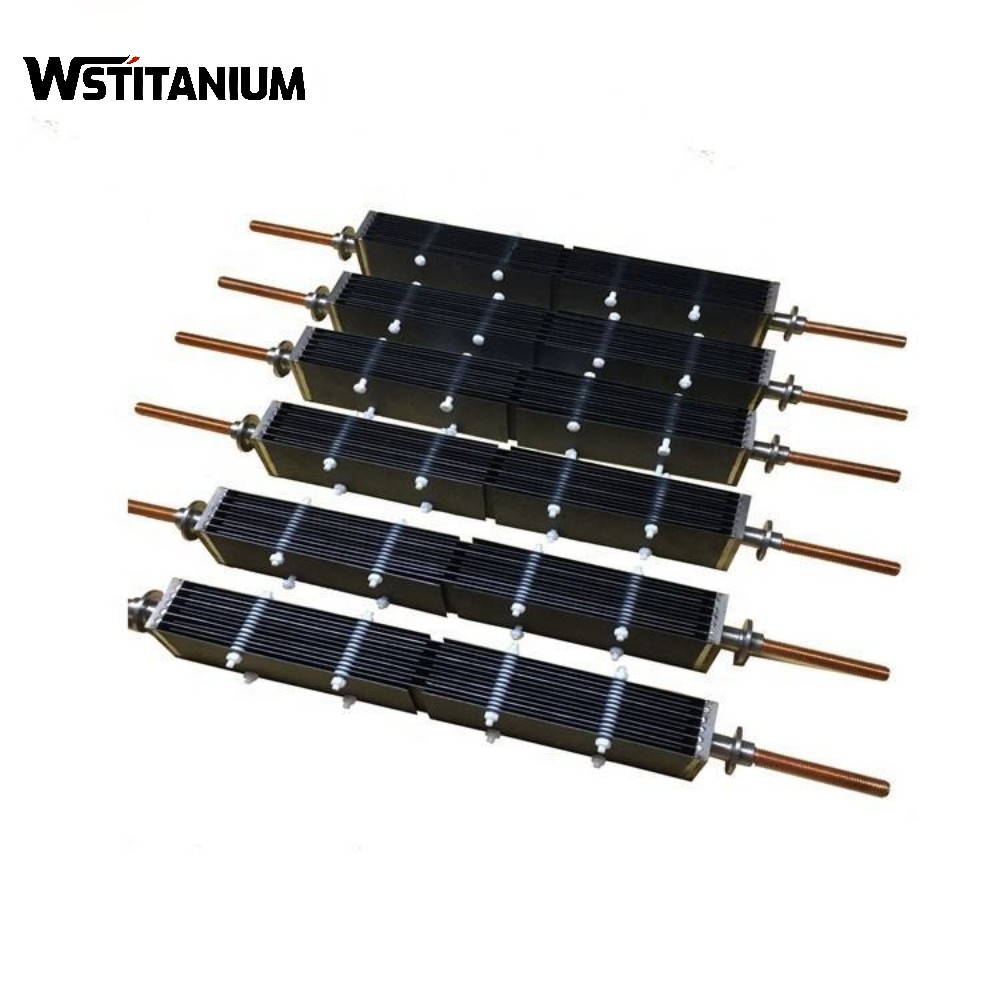

MMO Titanium Anode For Antibiotics

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Antibiotics, a major breakthrough in human medicine, have become a core substance for preventing and treating infectious diseases, safeguarding public health, and promoting the large-scale development of the livestock industry. However, the large amount of antibiotic residues generated during production, use, and disposal is gradually becoming a global environmental problem. Monitoring has found over 68 types of antibiotics in surface water, groundwater, and even drinking water, posing a potential threat to ecosystem balance and human health through their cumulative effects.

Mixed metal oxide titanium anodes (MMO titanium anodes), as highly efficient electrocatalytic electrodes, demonstrate breakthrough advantages in the field of antibiotic degradation thanks to the corrosion resistance and high catalytic activity of their titanium substrate.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Antibiotic Contamination

The use of antibiotics has permeated numerous key sectors, including healthcare and agriculture. As core drugs for treating bacterial infections, antibiotics such as penicillins and cephalosporins are widely used to treat respiratory and urinary tract infections, serving as a crucial line of defense for human health. Tetracyclines and macrolides are widely used in livestock and poultry farming to prevent animal diseases and promote growth. In the food industry, antibiotics are used to preserve fruits and vegetables and control bacteria in beer production.

Sources of Pollution

High-concentration wastewater generated by pharmaceutical production (with antibiotic concentrations reaching hundreds to thousands of mg/L) is a major source of pollution. Approximately 10%-30% of antibiotic raw materials are discharged with wastewater. Medical systems also generate antibiotic-containing medical wastewater and patient excrement. Animal husbandry manure and wastewater from livestock and poultry farming, where unabsorbed antibiotics can enter the environment, contribute to the spread of contamination. Furthermore, improper disposal of expired antibiotics exacerbates the spread of contamination.

Environmental Hazards

Low concentrations of antibiotics in the environment can induce bacteria to develop drug-resistant genes. Gene transfer can lead to the formation of superbugs, posing a significant challenge to clinical anti-infective treatment. Antibiotics are significantly toxic to aquatic organisms. For example, the half-inhibitory concentration (EC50) of tetracycline for algae is only 0.5-2.0 mg/L, which can disrupt the balance of aquatic food chains. For terrestrial organisms, antibiotic residues in soil can inhibit the activity of soil organisms such as earthworms, reducing soil fertility.

Human Health Threats

Antibiotics can enter the human body through drinking water and the food chain. Long-term accumulation may disrupt the endocrine system and affect immune function, posing potential risks to children’s development.

Hard to Treat

Amide bonds, hydroxyl groups, and other groups in their molecular structure make them chemically stable. Conventional treatment technologies generally remove less than 60% of these antibiotics. They also tend to form complexes with other pollutants in water, further complicating treatment.

Working Principle of the MMO Titanium Anode

The MMO titanium anode degrades antibiotics through electrocatalytic oxidation, integrating direct and indirect oxidation mechanisms. The degradation pathway is dynamically adjusted based on the antibiotic type, concentration, and water matrix characteristics, ultimately achieving harmless treatment.

(I) Direct Oxidation

Direct oxidation involves direct oxidation of antibiotic molecules on the anode surface through electron transfer, making it suitable for treating high-concentration antibiotic wastewater.

Antibiotic molecules are adsorbed onto the MMO coating surface through electrostatic attraction, hydrogen bonding, and other interactions. Under the influence of the electric field, the antibiotic molecules lose electrons and are oxidized to cationic free radicals. Chemical bonds subsequently break, such as the preferential cleavage of the β-lactam ring in β-lactam antibiotics, resulting in loss of antimicrobial activity.

Oxidation intermediates undergo further ring-opening reactions, converting them into small organic molecules such as carboxylic acids and aldehydes. Ultimately, some of these products are converted into CO₂, H₂O, and inorganic ions, achieving complete mineralization. Experiments have demonstrated that the direct oxidation efficiency of penicillin on the MMO anode surface can exceed 80%.

(II) Indirect Oxidation

Indirect oxidation utilizes reactive oxidative species (ROS) generated at the anode to degrade antibiotics and is a dominant method in low-concentration wastewater treatment.

H₂O or OH⁻ discharges at the anode surface to generate physically adsorbed ・OH. With a redox potential as high as 2.8 V, ・OH can indiscriminately attack active groups on antibiotic molecules, initiating a chain oxidation reaction and achieving “electrochemical combustion”-like degradation. This pathway can achieve a mineralization rate of over 90% for tetracycline antibiotics.

In a chlorine-containing electrolyte system, Cl⁻ is oxidized to Cl₂ at the anode, which further hydrolyzes to generate reactive chlorine species such as HClO/ClO⁻. These species efficiently oxidize amino and hydroxyl groups in antibiotic molecules. Simultaneously, metal oxides such as Ru and Ir in the MMO coating form a reversible redox couple, continuously oxidizing and degrading pollutants through valence state cycling. In chlorine-containing wastewater treatment, this pathway can increase antibiotic removal efficiency by over 30%.

(III) Synergistic Degradation

The MMO titanium anode can create a synergistic effect with other technologies, enhancing the antibiotic degradation effect. In the electro-Fenton system, H₂O₂ generated at the cathode reacts with Fe²⁺ to form ・OH, increasing the COD removal rate of ceftriaxone sodium from 65% in electrolysis alone to 92%.

Wstitanium’s Advantages

As a professional manufacturer of MMO titanium anodes, Wstitanium leverages a comprehensive R&D system and production technology. Its MMO titanium anodes, specifically designed for antibiotic treatment, demonstrate comprehensive advantages in performance, quality, and service.

(I) Raw Materials

Wstitanium has established a rigorous raw material quality control system. All titanium substrates are made of Gr1 pure titanium that meets ASTM standards, with a purity exceeding 99.6%. Through multiple processes such as sandblasting and pickling, the titanium substrate surface roughness is controlled to Ra 1.5-3.0 μm, ensuring coating adhesion >5 MPa.

The RuO₂ titanium anode, developed for high-salinity wastewater, boasts a 30% increase in chlorine evolution efficiency and a 25% increase in active chlorine production compared to industry standards.

The IrO₂-Ta₂O₅ titanium anode is designed for high-concentration wastewater. OH generation is increased by 45%, and the antibiotic mineralization rate can reach over 80%.

The introduction of rare earth doping technology reduces the coating’s energy consumption to below 0.5 μg/Ah, extending its lifespan by 50% compared to conventional coatings.

(II) Coating

Robot spraying is used for coating application, with a thickness tolerance controlled to ±2 μm to ensure coating uniformity.

High-temperature sintering is performed in a programmed temperature furnace, with the sintering temperature precisely controlled between 400-600°C to ensure a stable coating crystal structure. Testing is conducted by authoritative institutions, encompassing 12 indicators including coating composition, electrochemical properties, and corrosion resistance. The qualified rate of MMO titanium anodes remains above 99.5%.

(3) Customization

Wstitanium has thoroughly researched the characteristics of antibiotic wastewater from various industries and provides comprehensive customization services:

We manufacture anodes in various shapes, including flat, tubular, and mesh, tailored to the size of the treatment equipment. Mesh anodes can improve mass transfer efficiency by 50% and accelerate antibiotic degradation by 40%. We optimize coating formulations and electrode dimensions for antibiotic wastewater of varying concentrations (50-5000 mg/L) and types (such as β-lactams and tetracyclines), achieving a balance between energy consumption and efficiency.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Titanium Nuts