MMO Titanium Anode For Bridges

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Bridges, as core hubs of transportation infrastructure, are crucial for the stable operation of transportation networks and public safety. Under the long-term erosion of the natural environment and loads, corrosion has become the primary threat to bridge structural integrity. Coastal bridges face persistent erosion from high salt spray and tidal immersion. Inland bridges withstand the combined effects of industrial pollutants, acid rain, and soil electrolytes, leading to frequent problems such as steel corrosion and concrete carbonization and spalling.

Traditional anti-corrosion methods, such as coatings and sacrificial anodes, have significant limitations: coatings are susceptible to failure due to construction defects or external damage. Sacrificial anodes (such as aluminum and zinc anodes) have a short lifespan (typically 5-8 years) and unstable current output, making them unable to meet the century-long service requirements of long-span bridges. Against this backdrop, MMO titanium anodes (titanium-based metal oxide-coated anodes), with their core advantages such as dimensional stability, long lifespan, and high current efficiency, have become a key technological support for long-term bridge corrosion protection.

The MMO titanium anode is based on industrial pure titanium and coated with a mixed coating of precious metal oxides such as iridium, ruthenium, and tantalum. As the core component of the impressed current cathodic protection system, it can adapt to a variety of complex environments such as seawater, soil, and fresh water.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The application of MMO titanium anodes in bridge corrosion protection is based on impressed current cathodic protection technology. This electrochemical process alters the potential of the bridge’s metal structure (primarily steel bars and piles) to inhibit corrosion reactions.

(I) Cathodic Polarization

Corrosion of bridge steel structures is essentially a redox reaction occurring on the metal surface: iron (Fe) loses electrons to form iron ions (Fe²⁺). This is known as the anodic reaction (Fe → Fe²⁺ + 2e⁻). Electrons flow through the metal matrix to the cathode region, where they combine with oxygen and water to form hydroxide ions (O₂ + 2H₂O + 4e⁻ → 4OH⁻), ultimately forming rust (Fe(OH)₃).

The function of the MMO titanium anode is to force this reaction to change direction using an external DC power supply: the positive terminal of the power supply is connected to the MMO titanium anode, and the negative terminal is connected to the bridge’s steel structure. When powered, the MMO titanium anode releases electrons, becoming the current output terminal. Electrons flow through the electrolyte environment (seawater, soil, concrete pore fluid) to the steel structure surface, causing it to acquire excess electrons and undergo cathodic polarization. The surface potential of the steel structure drops below -0.85V (relative to a Cu/CuSO₄ reference electrode). At this point, the metal’s oxidation reaction, in which electrons are lost, is suppressed, and corrosion ceases.

(II) Anodic Catalysis

The catalytic activity of the MMO coating is key to ensuring efficient system operation. In different media, the coating catalyzes specific oxidation reactions: In chloride-containing environments such as seawater, the ruthenium-iridium coating catalyzes the conversion of chloride ions (Cl⁻) to chlorine gas (2Cl⁻ → Cl₂↑ + 2e⁻); in soil and freshwater, the iridium-tantalum coating catalyzes the conversion of water molecules to oxygen (2H₂O → O₂↑ + 4H⁺ + 4e⁻). These reactions efficiently release electrons, ensuring that the anode maintains a stable potential even at high current densities, preventing polarization from causing the protective current to decay.

MMO Titanium Anode Types

Based on the structural characteristics of bridges (such as steel piles, concrete beams, and pylons) and the service environment (seawater, soil, or freshwater), MMO titanium anodes have been classified into four main types.

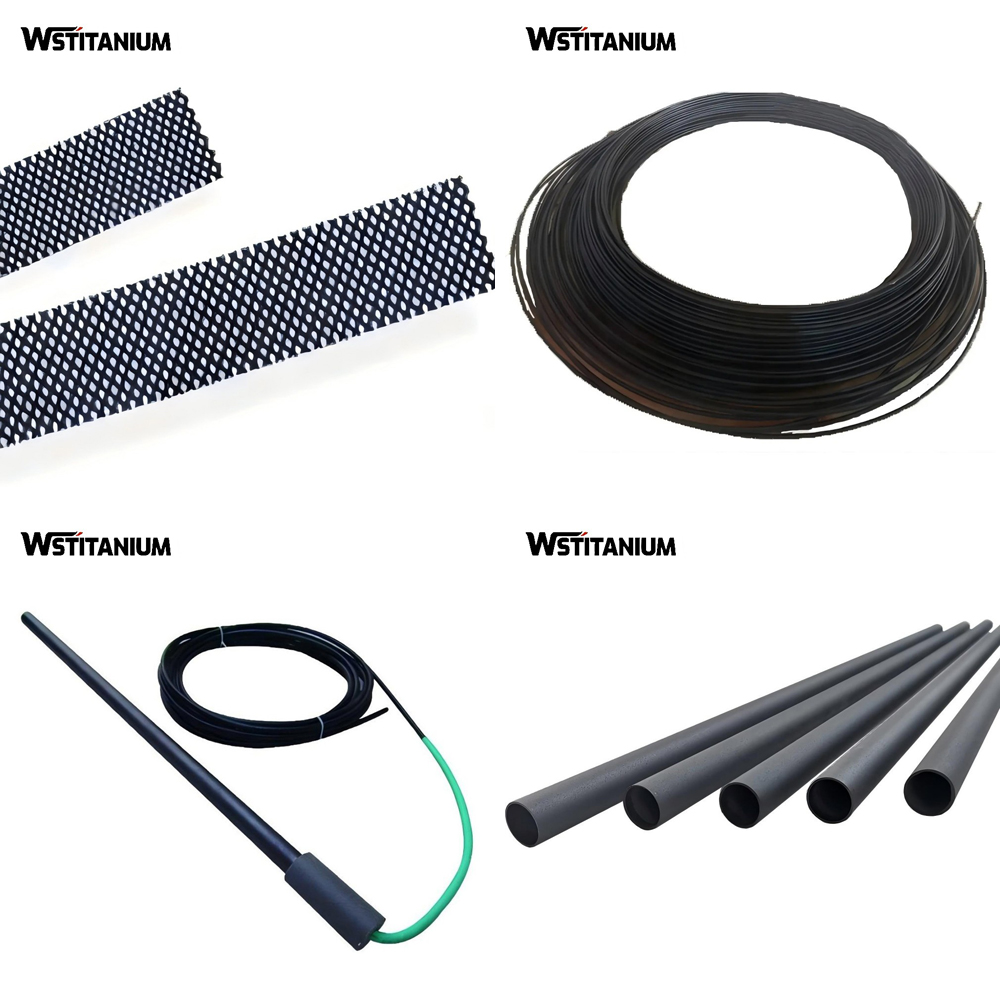

(I) Linear MMO Titanium Anode

Linear anodes are the most commonly used type for bridge corrosion protection. They consist of a titanium wire substrate (1.5-3.0mm diameter), an MMO coating, and an outer protective sheath. Auxiliary materials such as conductive polymers and activated carbon are used to create a flexible and bendable anode system. The coating is an iridium-tantalum (IrO₂/Ta₂O₅) coating, suitable for diverse environments such as soil, freshwater, and brackish water. Its protection radius can reach 3-5 meters. They are buried in the soil around bridge pier foundations or wrapped around the steel piles of offshore bridges.

(II) Tubular MMO Titanium Anodes

Based on an industrially pure titanium tube (10-50mm diameter), the inner or outer surface is coated with an MMO coating. These anodes offer high strength and impact resistance, making them suitable for protecting bridge piers in harsh environments. The coating uses a ruthenium-iridium coating (IrO₂/RuO₂/TiO₂), which prioritizes chlorine evolution. An iridium-tantalum coating is used for enhanced corrosion resistance in soil environments. It is used as anode for deepwater bridge piers and is buried vertically in sea mud or riverbeds.

(III) Strip MMO Titanium Anode

The Strip anode is made of a titanium ribbon substrate (6.35-12.7mm wide, 0.635mm thick) coated with an MMO coating, making it easy to deploy over large areas. The uniform iridium-tantalum coating provides exceptional corrosion resistance, showing no significant wear after a 5000-hour accelerated corrosion test. The large surface area allows for more uniform current distribution and a service life of up to 50 years. It is installed inside concrete bridge box girders or at the base of piers to protect densely distributed steel mesh.

(IV) Rod MMO Titanium Anode

The rod anode is a solid titanium rod (3.2-25mm diameter). A ruthenium-iridium coating is used for seawater environments. Iridium-tantalum coatings are used for freshwater/soil environments. A 25mm diameter rod anode has a rated current of up to 44.1A/m in seawater. It is used in areas with high corrosion risk, such as bridge bottoms and steel structure joints.

Wstitanium utilizes a high-purity titanium substrate exceeding 99.9%. Its fatigue strength is increased by 40%, making it less susceptible to deformation and cracking in complex stress environments such as soil compression and seawater impact. The coating utilizes a gradient coating technology: a gradient distribution of ruthenium, iridium, and tantalum enhances the coating-to-substrate bond strength to over 50 MPa. At a high current density of 15 A/dm², the coating loss rate is as low as 1 mg/A.a., extending the lifespan by 50% compared to industry-leading products—up to 40 years in soil and 25 years in seawater.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs