MMO Titanium Anode For Chlor-Alkali

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

The chlor-alkali industry, a core pillar of the basic chemical industry, produces three key chemical raw materials: chlorine, hydrogen, and caustic soda, through the electrolysis of saturated brine. This industry extensively supports the development of downstream industries such as plastics, textiles, pharmaceuticals, and papermaking.

Mixed metal oxide titanium anodes (MMO titanium anodes) have completely overcome the challenges of traditional graphite anodes, including rapid corrosion and loss, low current efficiency, and high pollutant emissions. This has helped propel global chlor-alkali production capacity to over 41 million tons per year, increasing electrolysis efficiency by 40% and reducing energy consumption by 30%. MMO titanium anodes have become a standard core component in the modern chlor-alkali industry.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Industrial Principles of MMO Titanium Anodes

The core principle behind the application of MMO titanium anodes in the chlor-alkali industry is electrochemical catalysis. The fundamental reaction in the chlor-alkali industry is the electrolytic decomposition of saturated brine (NaCl solution). MMO titanium anodes act as anodes, generating the chloride ion oxidation reaction:

Charge Transfer

Under an applied electric field, the noble metal oxide active sites in the MMO coating capture chloride ions (Cl⁻) in the electrolyte, oxidizing Cl⁻ to Cl₂ via electron transitions. The anodic reaction equation is: 2Cl⁻ – 2e⁻ = Cl₂↑. The crystal structure of the ruthenium-based coating provides a suitable adsorption energy and reaction pathway for chloride ions, reducing the activation energy of the reaction by 20%-30% and significantly increasing the reaction rate.

Catalytic Control

The presence of OH⁻ ions in the chlor-alkali electrolyte can potentially lead to an oxygen evolution side reaction (4OH⁻ – 4e⁻ = O₂↑ + 2H₂O). The coating on the MMO titanium anode ensures that the overpotential for the chlorine evolution reaction is significantly lower than that for the oxygen evolution reaction. Chlorine purity can reach over 99.95%.

Cathode Cooperative Reaction

Electrons generated at the anode are transferred to the cathode via an external circuit, reducing water molecules to form hydrogen and sodium hydroxide. The reaction equation is: 2H₂O + 2e⁻ = H₂↑ + 2OH⁻. The dimensional stability of the MMO titanium anode ensures a constant inter-electrode spacing within a ±0.5mm tolerance. Cell voltage fluctuations are controlled within ±2%, providing a stable electric field environment for the cathode reaction.

Advantages of MMO Titanium Anodes

MMO titanium anodes optimize energy efficiency in the chlor-alkali industry through multiple mechanisms.

Reduced Overpotential: The catalytic coating reduces the overpotential for chlorine evolution from 3.2V to below 2.8V, reducing energy consumption.

Increased Current Density: The mesh structure supports an increase in current density from 8A/dm² to 17A/dm², significantly increasing production capacity within the same cell volume.

Reduced side reaction losses: Highly selective catalysis increases current efficiency to 94%-97%, significantly higher than the approximately 85% of graphite anodes, reducing energy consumption.

Extended maintenance intervals: Anode life is extended from 8 months to 6-8 years, reducing production losses caused by downtime for anode replacement and improving overall energy efficiency by 15%-25%.

Types of MMO Titanium Anodes

The core reaction in the chlor-alkali industry is chlorine evolution, placing stringent demands on the anode’s catalytic specificity, resistance to chlorine corrosion, and current-carrying capacity. MMO titanium anodes suitable for the chlor-alkali industry are primarily classified into the following categories:

1. Ruthenium-Coated Titanium Anodes

This is the most widely used type of MMO titanium anode in the chlor-alkali industry. The core coating system uses ruthenium dioxide (RuO₂) as the active component, typically doped with oxides of elements such as iridium (Ir) and titanium (Ti) to form a composite structure. Typical formulations include a RuO₂-IrO₂ or RuO₂-TiO₂ gradient coating. Ruthenium exhibits strong catalytic activity for chloride ion oxidation, enabling the chlorine evolution overpotential to be controlled at ≤1.36V (vs. SHE), significantly reducing electrolysis energy consumption.

2. Ruthenium-Ir-Tantalum-Coated Titanium Anodes

Ruthenium-Ir-Tantalum-Coated Titanium Anodes are used in large-scale chlor-alkali plants with high current densities and long operating cycles. Its catalytic synergistic effect can increase current efficiency to 94%-97%, and chlorine purity reaches 99.98%.

3. Platinum-coated titanium anodes

For applications requiring extremely high purity, platinum-coated titanium anodes enable chlorine purity exceeding 99.99%. However, their high cost makes them suitable only for high-end niche applications.

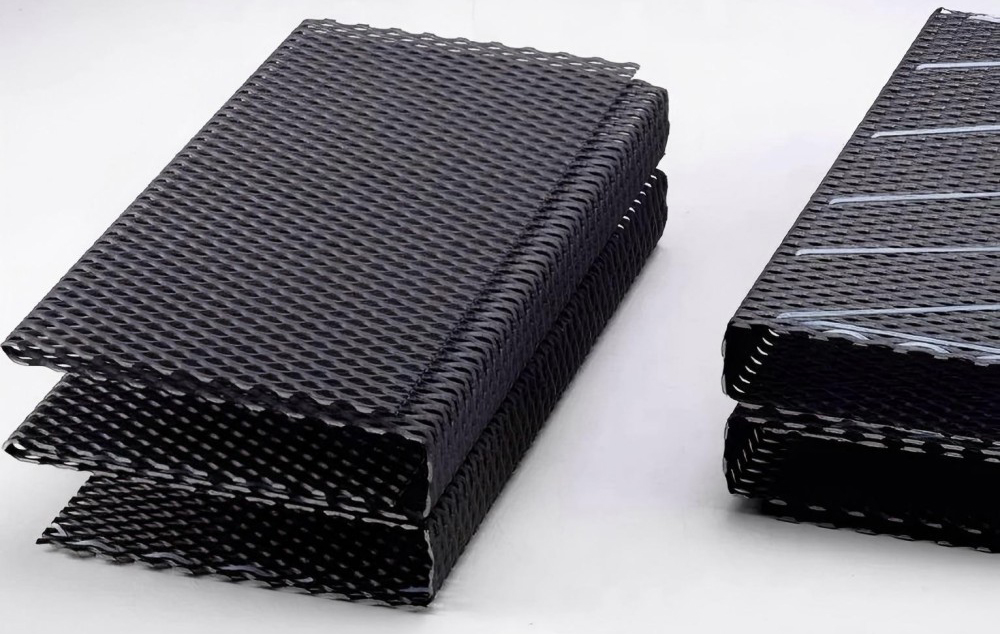

4. Mesh MMO Titanium Anode

Based on a titanium mesh, it boasts a porosity of 60%-80% and a specific surface area 3-5 times greater than flat electrodes, significantly enhancing electrolyte mass transfer efficiency and reaction contact area. Its three-dimensional mesh structure accommodates precise designs with a 0.3mm inter-electrode spacing and withstands mechanical stresses of 200N/cm² without deformation.

5. Tubular MMO Titanium Anode

Made from a hollow titanium tube with a catalytic coating, it is primarily used in deep-well electrolyzers or chlorine-water circulation systems. Its cylindrical structure facilitates uniform electrolyte flow across the reaction interface, reducing concentration polarization and maintaining stable operation even at high flow rates (3m/s).

6. Plate MMO Titanium Anode

Made from a 3-5mm thick pure titanium plate (Gr1/Gr2), sandblasted and grooved, and then coated with a catalytic coating, it offers a simple structure and low manufacturing cost. The plate-shaped anode has a strong current carrying capacity.

With customized coating technology, precision manufacturing and customized services, Wstitanium’s MMO titanium anodes have significant advantages in catalytic efficiency, corrosion resistance and cost control, providing chlor-alkali companies with solutions that are both technologically advanced and economically feasible.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Titanium Nuts