MMO Titanium Anode for Cyano

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Cyanide, due to its extremely high toxicity, has become a key target for environmental regulation. With increasingly stringent global environmental regulations, treatment standards for cyanide-containing wastewater and exhaust gases are constantly rising. Traditional treatment technologies, such as chemical precipitation and biodegradation, are increasingly exposed to limitations such as low removal efficiency, high risk of secondary pollution, and high operation and maintenance costs.

MMO titanium anodes (mixed metal oxide titanium anodes), as highly efficient electrochemical materials, demonstrate irreplaceable advantages in the field of cyanide deep treatment due to their excellent electrocatalytic activity, chemical stability, and exceptionally long service life. These anodes are based on industrially pure titanium and coated with ruthenium, iridium, tantalum, and platinum, enabling the efficient conversion of cyanide into non-toxic and harmless substances.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Cyanide Applications and Pollution

Cyanide is irreplaceable in multiple industrial sectors, with applications primarily concentrated in the following four sectors.

Metallurgy: In gold mining and refining, cyanide forms soluble complexes with precious metals such as gold and silver, enabling the separation and extraction of target metals from ore.

Electroplating: Cyanide is used as a complexing agent in the preparation of electroplating solutions, effectively controlling the rate of metal ion precipitation and forming a uniform, dense coating. It is commonly used for plating zinc, copper, and silver.

Chemical Synthesis: Cyanide serves as a key intermediate in the synthesis of pharmaceuticals, pesticides, dyes, and other products. For example, cyanide is used as a raw material in the production of certain antibiotics and herbicides.

Other Industries: Cyanide is used for surface hardening in metal heat treatment. In the electronics industry, it is used for etching semiconductor materials. Its toxicity is also exploited in some sectors to create fumigants.

Cyanide pollution primarily stems from industrial wastewater discharge, waste residue, and exhaust gas emissions. Cyanide-containing wastewater is the primary source of pollution. Untreated discharge of rinsing wastewater from the electroplating industry, leachate from the metallurgical industry, and residual reaction liquids from chemical synthesis, among others, can cause serious environmental harm.

The toxicity of cyanide is primarily due to its inhibitory effect on respiratory enzymes in organisms, rapidly disrupting the cellular respiratory chain and causing tissue hypoxia. The lethal dose for humans is extremely low (an oral lethal dose of sodium cyanide is only 10-20 mg). For aquatic ecosystems, even low concentrations of cyanide (above 0.04 mg/L) can kill fish and other aquatic organisms, disrupting the aquatic balance. Furthermore, cyanide can be converted into more toxic compound cyanides in the environment or accumulate through the food chain, posing a long-term threat to the ecological environment and human health.

Working Principle of the MMO Titanium Anode

The core of the MMO titanium anode’s cyanide treatment is the electrochemical oxidation reaction, which decomposes toxic cyanide ions (CN⁻) into non-toxic carbon dioxide (CO₂) and nitrogen (N₂) at the electrode surface. Essentially, this process enhances the efficiency of oxidative degradation through the anode’s high catalytic activity.

Under the action of direct current, cyanide-containing wastewater undergoes a reaction within the electrolytic cell, with the MMO titanium anode primarily performing the oxidative degradation function.

Direct Oxidation: Cyanide ions are oxidized directly by losing electrons at the anode surface. The reaction equation is: 2CN⁻ + 8OH⁻ – 10e⁻ → 2CO₃²⁻ + N₂↑ + 4H₂O. The ruthenium and iridium oxides in the MMO coating exert high catalytic activity, enabling cyanide ions to be oxidized at a relatively low potential.

Indirect Oxidation: If the wastewater contains electrolytes such as chloride ions, a chlorine evolution reaction simultaneously occurs at the anode, producing chlorine gas (Cl₂). Chlorine further reacts with water to form hypochlorous acid (HClO). As a strong oxidant, hypochlorous acid indirectly oxidizes cyanide ions, using the reaction formula: CN⁻ + ClO⁻ + H₂O → CNO⁻ + Cl⁻ + 2OH⁻. The resulting cyanate (CNO⁻) is further hydrolyzed into carbon dioxide and nitrogen, rendering it completely harmless.

The cathode primarily undergoes a reduction reaction, recovering heavy metal ions (such as Cu²⁺ and Ni²⁺) from the wastewater and forming a metal elemental deposit, achieving the dual goals of resource recovery and pollution control.

MMO Titanium Anode Types

Different types of MMO titanium anodes are selected depending on the water quality characteristics, treatment scale, and equipment structure of cyanide-containing wastewater. MMO titanium anodes are classified based on structural morphology, coating composition, and application scenarios. Common types are as follows:

Mesh MMO titanium anodes: Based on ASTM B265 Gr1 grade titanium mesh, coated with a RuO₂-IrO₂-TiO₂ composite coating. The mesh density ranges from 50-200 mesh. They offer a large surface area and uniform current distribution. Suitable for treating electroplating rinse wastewater in small and medium-sized electrolytic cells, they can reduce effluent cyanide concentrations to below 0.5 mg/L and have a service life of over five years.

Plate MMO titanium anodes: Manufactured from 0.5-3 mm thick titanium plates, their surfaces are sandblasted and roughened before being coated with an oxide coating. They offer high structural strength and are easy to install and maintain. Primarily used for treating high-concentration cyanide-containing wastewater (CN⁻ concentration > 100mg/L), it maintains stable operation at a current density of 1500A/m² and has demonstrated an accelerated lifespan of over 120 hours.

Tubular MMO Titanium Anodes: 50-200mm Φ titanium tubes coated with an IrO₂-Ta₂O₅ coating are suitable for continuous flow electrolysis reactors, enhancing contact between wastewater and the electrode. They are particularly well-suited for treating tailings in the metallurgical industry, with a single anode capable of treating up to 5-10m³/day.

Strip MMO Titanium Anodes: 6.35-12.7mm wide, 0.635mm thick, coated titanium strips are available in custom lengths up to 152m. They are primarily used for leaching cyanide-containing wastewater in large storage tanks or underground, with a service life of up to 50 years in soil environments.

Ruthenium-Iridium Coated Anodes: Utilizing RuO₂-IrO₂ as the active component and TiO₂ as the inert carrier, they offer a chlorine evolution potential of ≤1.2V and are suitable for treating cyanide-containing wastewater containing chloride ions. They enhance indirect oxidation and achieve current efficiencies exceeding 95%.

Iridium-Tantalum Coated Anodes: Composed of an IrO₂-Ta₂O₅ coating, they offer a higher oxygen evolution potential and are suitable for treating cyanide-containing wastewater with low chloride content. They avoid interference from the chlorine evolution reaction and offer more stable catalytic activity under alkaline conditions.

Customized Anodes: Customized MMO titanium anodes with specialized structures are available for specialized applications. These include flexible anode cables (Ø8mm PTFE encapsulation) for deep well treatment, micro-mesh anodes for precision electroplating wastewater, and intelligent sensing anodes with integrated sensors that monitor coating loss and reaction status in real time, enabling digital control.

Wstitanium strictly selects ASTM B265 Gr1 grade industrially pure titanium as its substrate. Its chemical composition is precisely controlled, with a carbon content of ≤0.08% and an iron content of ≤0.20%, ensuring excellent corrosion resistance and mechanical strength. The coating utilizes a proprietary gradient composite system. By adjusting the molar ratio of RuO₂ to IrO₂ (adjustable from 1:1 to 3:1), it adapts to cyanide-containing wastewater with varying chloride ion concentrations. The precious metal loading is controlled at 10-12g/m², ensuring catalytic activity while reducing costs. Targeted to the characteristics of cyanide oxidation reactions, the coating thickness is precisely controlled at 20-50μm, and the porosity is optimized to 35-45%, increasing the effective reaction area by 5-8 times and boosting the cyanide degradation rate by over 30% compared to conventional products.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

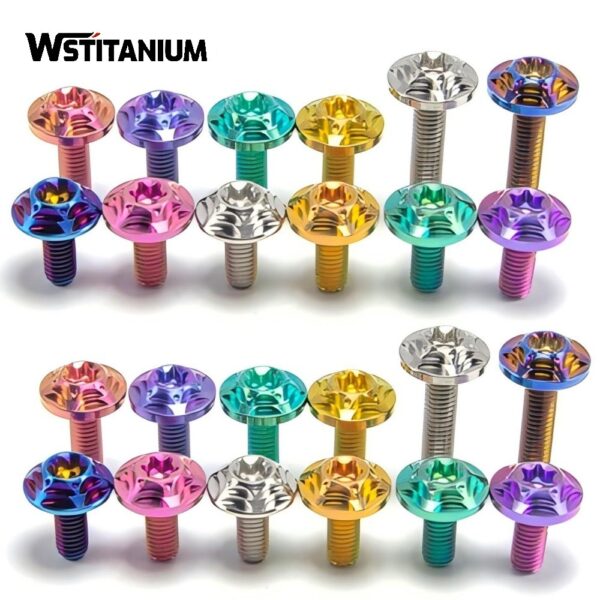

Anodized Titanium Screws

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts