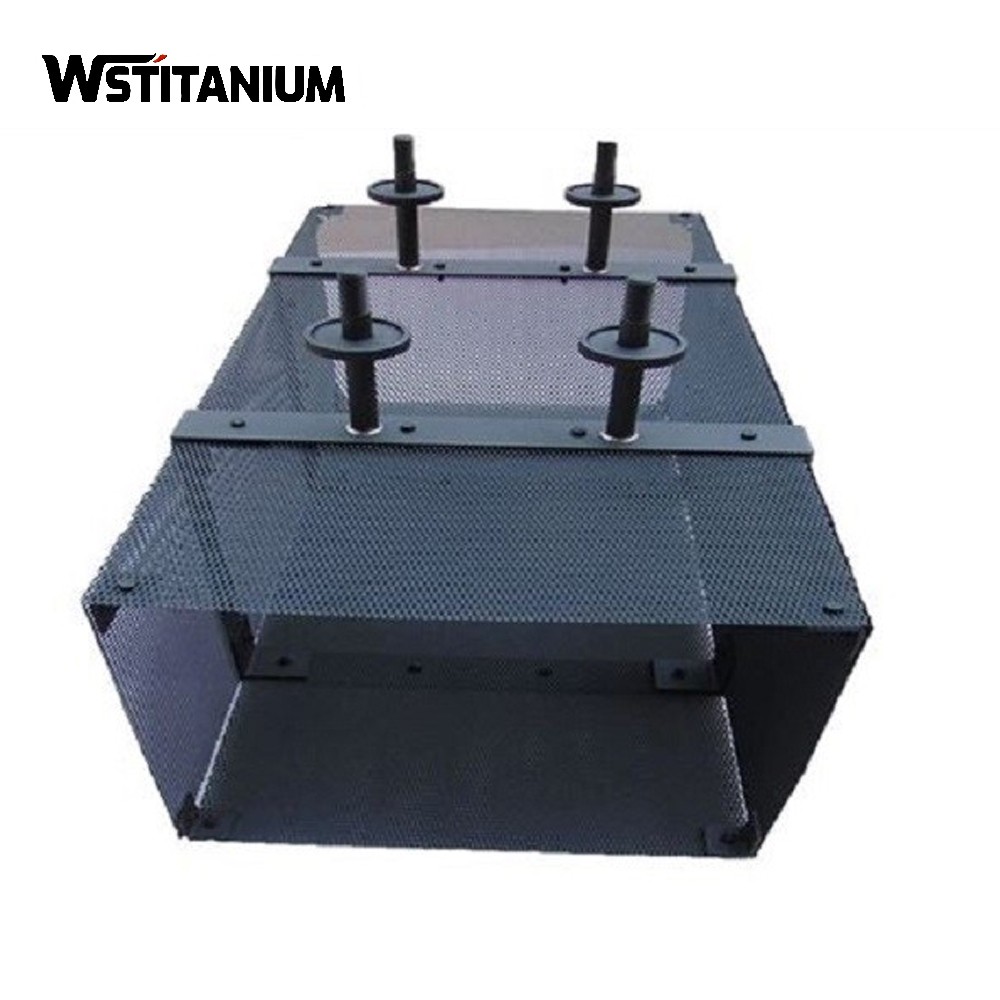

MMO Titanium Anode For Dye

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Dyes, as core raw materials that impart color to materials, are indispensable in modern industrial systems. However, dye wastewater has become a prominent challenge in global industrial wastewater treatment. With the rapid development of industries such as textile printing and dyeing, leather, and paper printing, dye wastewater discharge has increased annually.

Traditional treatment technologies, such as biodegradation and adsorption, are generally limited by low decolorization rates, incomplete degradation, and the generation of secondary pollution when dealing with the complex and highly stable composition of modern synthetic dyes. MMO titanium anodes (mixed metal oxide-coated titanium anodes), a highly efficient electrochemical material, utilize industrially pure titanium as a substrate and are coated with a composite coating of precious metal oxides such as ruthenium, iridium, and tantalum. Their excellent electrocatalytic activity, chemical stability, and exceptionally long service life make them uniquely advantageous in the advanced treatment of dye wastewater.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Dye Wastewater Pollution

The textile printing and dyeing industry is the primary source of dye wastewater. During the dyeing, printing, and fixing processes for cotton, linen, silk, and chemical fiber fabrics, approximately 10%-20% of the dye is discharged with the rinse water, resulting in wastewater with high chroma and high organic matter concentrations. This generates an average of 200-300 tons of wastewater per ton of fabric. In the synthesis of azo dyes, anthraquinone dyes, and reactive dyes, the raw material conversion rate is typically only 70%-80%. Unreacted aromatic compounds, intermediates, and by-products enter the wastewater system during the washing and separation processes, resulting in a complex composition and high toxicity.

High chroma: The wastewater is dark in color, remaining noticeable even after dilution thousands of times. For example, azo dye wastewater exhibits vibrant hues such as red and yellow, while anthraquinone dye wastewater often exhibits blue or black hues. These wastewaters not only affect water transparency but also pose potential toxic risks.

High pollutant concentrations: COD (chemical oxygen demand) typically ranges from 800-5000 mg/L, with some high-concentration wastewater reaching tens of thousands of mg/L. It also contains large amounts of suspended solids, salt, and additives, placing a significant burden on water purification.

High toxicity: Aromatic amine compounds, heavy metals (such as copper, chromium, and nickel), and formaldehyde contained in wastewater are carcinogenic, teratogenic, and mutagenic, causing irreversible harm to organisms.

Recalcitrant to degradation: Most synthetic dyes have stable conjugated double bonds, with B/C ratios (biodegradability ratios) often below 0.2, making them extremely biodegradable and difficult to effectively degrade using traditional treatment technologies.

If dye wastewater is discharged directly without treatment, it can rapidly disrupt the ecological balance of aquatic plants, hindering photosynthesis and poisoning and killing fish and other organisms. If it seeps into the soil, it can contaminate groundwater and accumulate through the food chain, impacting human health.

Working Principle of MMO Titanium Anodes

The core of MMO titanium anode treatment of dye wastewater is electrocatalytic oxidation technology. Strong oxidizing species are generated on the electrode surface, destroying the dye’s molecular structure and completely degrading it into non-toxic and harmless substances. Essentially, this technology uses electrical energy to drive redox reactions, achieving harmless conversion of pollutants.

Direct Electrocatalytic Oxidation

Dye molecules adsorb onto the MMO coating surface through diffusion. At the anode, they directly lose electrons and undergo an oxidation reaction. Stable structures such as conjugated double bonds and benzene rings are broken, gradually decomposing into small organic molecules and ultimately converting to CO₂ and H₂O. For example, the -N=N- bond of azo dyes is directly oxidized and broken at the anode, generating the corresponding amine compounds, which are further oxidized to inorganic compounds.

Indirect Electrocatalytic Oxidation

The high catalytic activity of the MMO coating promotes oxidation reactions in water molecules or electrolytes, generating strong oxidizing species such as hydroxyl radicals (・OH) and reactive oxygen species. The hydroxyl radical, with its redox potential as high as 2.8V, can indiscriminately attack dye molecules, rapidly destroying their chromophores and molecular backbones, achieving efficient decolorization and organic degradation. The reaction equation can be expressed as: H₂O → ・OH + H⁺ + e⁻, ・OH + dye molecules → CO₂ + H₂O + inorganic salts. If the wastewater contains electrolytes such as chloride ions, a chlorine evolution reaction occurs at the anode to produce Cl₂, which is further converted into oxidants such as hypochlorous acid (HClO), enhancing the indirect oxidation effect. This makes it particularly suitable for treating high-salt dye wastewater.

The excellent performance of the MMO titanium anode stems from the synergistic effect of the titanium substrate and the composite coating. The precious metal oxides, such as IrO₂ and RuO₂, in the coating possess excellent electron transfer properties, significantly reducing the activation energy of the oxidation reaction. This allows for efficient degradation of dye molecules at lower potentials, with a reaction rate 3-5 times higher than that of traditional graphite electrodes. The polarizability of the MMO coating can be controlled within 40mV, which is much lower than the 200mV of the graphite anode. It can effectively reduce the cell voltage during the electrolysis process and reduce the energy consumption per unit COD removal by more than 30% compared with traditional electrodes.

MMO Titanium Anode Types

Different types of MMO titanium anodes are selected depending on the water quality characteristics of dye wastewater, treatment scale, and equipment structure. Key classification criteria include structural morphology, coating composition, and application scenarios.

Mesh MMO titanium anodes: Based on ASTM B265 Gr1 grade titanium mesh, coated with a RuO₂-IrO₂ composite coating. The mesh density ranges from 50-200 mesh, with a porosity of 60%-80%. The specific surface area is 3-5 times higher than that of flat electrodes. Suitable for treating textile printing and dyeing bleaching wastewater in small and medium-sized electrolytic cells, they achieve color removal rates exceeding 90% and COD removal rates exceeding 85% at a current density of 1000A/m², with a service life exceeding 5 years.

Plate MMO titanium anodes: Made of 0.5-3mm thick titanium plates that undergo a sandblasting roughening process and are coated with an IrO₂-Ta₂O₅ coating, they offer high structural strength and uniform current distribution. Primarily used for treating high-concentration dye wastewater (COD > 2000mg/L), such as residual liquid from dye manufacturing, it maintains stable operation at a high current density of 2000A/m², with an accelerated lifespan test exceeding 120 hours.

Tubular MMO Titanium Anode: 50-200mm Φ titanium tubes coated with a special composite coating are suitable for continuous flow electrolysis reactors, enhancing contact between wastewater and the electrode. They are particularly well-suited for treating fluidized wastewater in the leather industry, with a single anode capable of treating 5-10m³/day.

Flexible MMO Titanium Anode: Based on a titanium wire substrate, coated with an IrO₂-Ta₂O₅ coating and wrapped with an acid- and alkali-resistant braided outer layer, it is bendable and coilable, adapting to complex treatment equipment or underground infiltration systems. Suitable for treating dye wastewater in storage tanks, it adheres tightly to the tank wall, eliminating potential blind spots and boasts a service life exceeding 50 years.

Ruthenium-Iridium Anodes: Utilizing RuO₂-IrO₂ as the active components, they offer a chloride evolution potential of ≤1.36V and are suitable for high-salt dye wastewater containing chloride ions. They enhance indirect oxidation and achieve current efficiencies exceeding 95%. In textile printing and dyeing wastewater treatment, combined with a three-dimensional electrode system, they achieve COD removal rates of up to 85% and color removal rates exceeding 90%.

Iridium-Tantalum Anodes: Composed of an IrO₂-Ta₂O₅ coating, they offer a higher oxygen evolution potential and are suitable for dye wastewaters with low chloride content, avoiding interference from the chlorine evolution reaction. Their catalytic activity is more stable under acidic conditions, making them particularly suitable for treating anthraquinone dye wastewater.

Specially Doped Coated Anodes: Utilizing PbO₂-MnO₂ doped coatings or rare earth element modified coatings, they optimize catalytic performance for difficult-to-degrade dye molecules. They are specifically designed for treating highly toxic and stable dye wastewaters, increasing decolorization rates by over 40% compared to conventional coatings.

Special customization Anodes: To meet the needs of special scenarios, special MMO titanium anodes can be customized, such as micro-sheet anodes (size 10×20mm) for laboratory tests, modular combination anodes for large oxidation tanks, and smart anodes with integrated potential monitoring function, which can provide real-time feedback on the reaction status and achieve precise control.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts