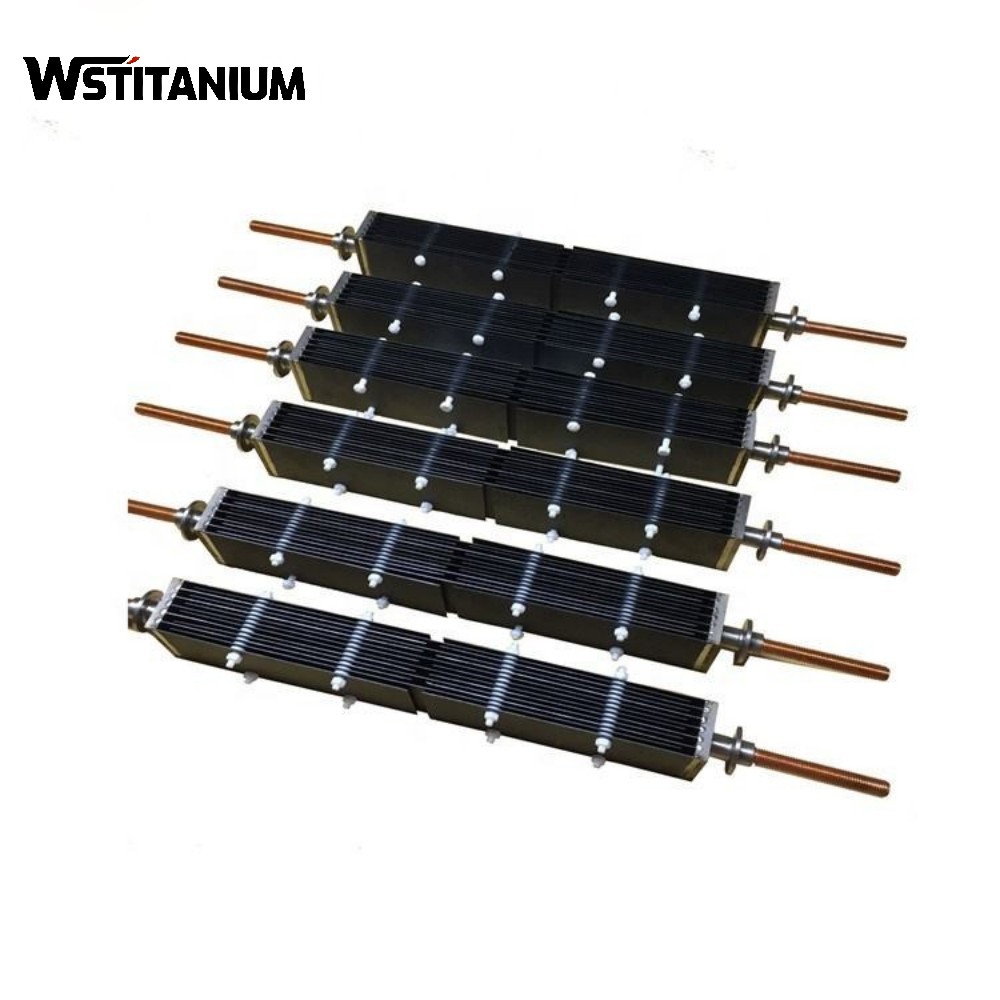

MMO Titanium Anode For Electrolytic Aluminum

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

MMO titanium anodes (titanium-based metal oxide-coated anodes), as high-performance inert anodes, offer a viable solution for achieving “carbon-free electrolysis” in the aluminum electrolytic industry. MMO titanium anodes do not participate in the chemical reaction during electrolysis, completely eliminating carbon dioxide emissions while also reducing cell voltage by 0.3-0.5V. This reduces power consumption per ton of aluminum from 13,500 kWh to below 12,000 kWh, potentially achieving energy savings of over 10%.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The fundamental principle behind the use of MMO titanium anodes in aluminum electrolysis is to establish a stable electrochemical reaction within a high-temperature molten electrolyte environment. The fundamental reaction in aluminum electrolysis is the electrolytic decomposition of molten aluminum oxide in a cryolite electrolyte. The MMO titanium anode acts as an inert anode, where oxygen ions undergo oxidation and oxygen evolution.

Catalytic Reaction

Oxygen ions (O²⁻) in the molten electrolyte migrate to the surface of the MMO titanium anode and are adsorbed by the active sites of the precious metal oxide in the coating. These sites catalyze the oxidation of O²⁻ through electron transfer, producing oxygen gas. The anodic reaction equation is: 2O²⁻ – 4e⁻ = O₂↑. The crystal structure of iridium-ruthenium oxide provides a suitable reaction pathway for oxygen ions, reducing the activation energy of the reaction by over 30%.

Inert Protection

The dense structure and chemical stability of the MMO coating prevent the anode itself from participating in the reaction, thus avoiding the consumption and CO₂ emissions associated with traditional carbon anodes. At the same time, the coating effectively blocks the diffusion of fluoride and sodium ions from the molten electrolyte into the titanium substrate, protecting it from corrosion and ensuring long-term stable operation of the anode.

Cathode Cooperative Reaction

Electrons generated at the anode are transferred to the cathode via an external circuit, where aluminum ions (Al³⁺) are reduced to molten aluminum. The reaction equation is: Al³⁺ + 3e⁻ = Al. The dimensional stability of the MMO titanium anode ensures a constant inter-electrode spacing within ±1mm and cell voltage fluctuations within ±3%, providing a stable electric field environment for the cathode reaction.

Types of MMO Titanium Anodes

Aluminum electrolysis production faces high-temperature molten electrolyte environments of 950-1000°C, and the electrolyte is highly corrosive, placing stringent demands on the high-temperature, thermal shock, and corrosion resistance of MMO titanium anodes.

1. Iridium-Tantalum Titanium Anodes

This is the most mature type of MMO titanium anode used in the aluminum electrolysis industry. The core coating system utilizes iridium dioxide (IrO₂) as the active component, doped with tantalum pentoxide (Ta₂O₅) to form a composite structure. The typical formulation is an IrO₂-Ta₂O₅ gradient coating, with a coating thickness of 30-50μm. This type of anode exhibits excellent corrosion resistance in the Na₃AlF₆-Al₂O₃ molten system, with a corrosion rate controlled to below 0.002mm/year. Its low oxygen evolution overpotential, around 1.5V (vs. Al/Al³⁺), reduces energy loss in the anodic reaction and is suitable for experimental applications in medium- and low-temperature aluminum electrolysis.

2. Iridium-Ruthenium Titanium Anode

For industrial electrolysis applications with high temperatures and high current densities, the Iridium-Ruthenium-Tantalum Coated Titanium Anode reduces the oxygen evolution overpotential to below 1.4V while also improving the coating’s thermal conductivity, preventing localized overheating and spalling.

3. Rare Earth-Modified Titanium Anode

To reduce precious metal usage and costs, rare earth-modified coatings incorporate rare earth oxides such as cerium oxide (CeO₂) and lanthanum oxide (La₂O₃) into the iridium-tantalum system, forming a quaternary composite coating. Rare earth elements refine the coating’s grain structure and increase its density, reducing precious metal usage by 20%-30% while maintaining corrosion resistance. The outstanding advantages of this type of anode are cost controllability and technical compatibility. Its thermal shock resistance is improved by 40%, allowing it to adapt to temperature fluctuations during electrolytic cell startup and shutdown. It is currently primarily used in small test cells and pilot plants.

4. Plate MMO Titanium Anode

This anode is made from a 5-8mm thick Gr2 pure titanium plate, sandblasted, activated with acid, and then coated with a catalytic coating. The surface flatness tolerance is ≤0.5mm/m. The plate anode has a simple structure and mature manufacturing technology. In a 30kA small test cell, the plate anode stabilizes the cell voltage at around 4.0V, 0.4V lower than carbon anodes.

5. Tube MMO Titanium Anode

This anode uses a pure titanium tube with an outer diameter of 20-30mm as the base, coated on the surface. The tubular structure has a specific surface area 2-3 times greater than that of a flat plate anode. Its advantage lies in its ease of installation and maintenance. Damaged anodes can be replaced individually without stopping the cell for maintenance.

6. Mesh MMO Titanium Anode

This anode utilizes titanium wire woven into a mesh matrix with a porosity of 60%-70%. This mesh structure optimizes current distribution, keeping current density deviation within ±5%, while also reducing electrolyte flow resistance and improving alumina dissolution efficiency. The titanium wire diameter of this anode is 2-3mm, the mesh size is 10×10mm, and the contact resistance is ≤5mΩ. In a simulated high current density environment (1.2A/cm²), the mesh anode’s current efficiency is 3% higher than that of a plate anode, while also keeping the impure iron content in the molten aluminum below 0.01%.

Wstitanium Advantages

As a leading company in China’s electrochemical field, Wstitanium has developed MMO titanium anodes, targeting the demanding operating conditions of the aluminum electrolysis industry through material innovation, technological upgrades, and comprehensive quality control. This has resulted in significant technical and application advantages.Leveraging 15 years of experience in electrolytic material research and development, Wstitanium has built a database of coating formulations covering various electrolysis scenarios. We can customize solutions based on your current density, electrolyte composition, and operating cycle requirements.

Precise Catalytic Control: Utilizing nano-particle dispersion technology, we optimize the ratio of the IrO₂-RuO₂-Ta₂O₅ ternary components, achieving an oxygen evolution overpotential as low as 1.38V, a 5% reduction from the industry average. This can save over 1200kWh per ton of aluminum produced in a 450kA electrolytic cell.

Enhanced Corrosion Resistance: Developed gradient composite coating technology, forming a 5-8μm thick Ta₂O₅ anti-oxidation layer on the surface, an iridium-ruthenium catalytic layer in the middle, and a titanium-based transition layer at the bottom. In a simulated 1000°C molten electrolyte environment, the coating degradation rate was less than 0.5μm/year after 2000 hours of continuous operation.

Cost-Optimized Design: Through rare earth modification and precious metal nano-loading technology, while maintaining performance, precious metal usage was reduced by 25%, reducing the cost per ton of anode material by 18%-22%, improving technical and economic efficiency.

MMO titanium anodes, with their exceptional chemical inertness, catalytic activity, and structural stability, offer a revolutionary solution to addressing the challenges of carbon emissions and high energy consumption in the aluminum electrolytic industry. Through customized coating technology, precision manufacturing, and comprehensive lifecycle services, Wstitanium’s MMO titanium anodes offer significant advantages in catalytic efficiency, corrosion resistance, and cost control, providing a reliable option for aluminum electrolytic companies seeking technological upgrades.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt