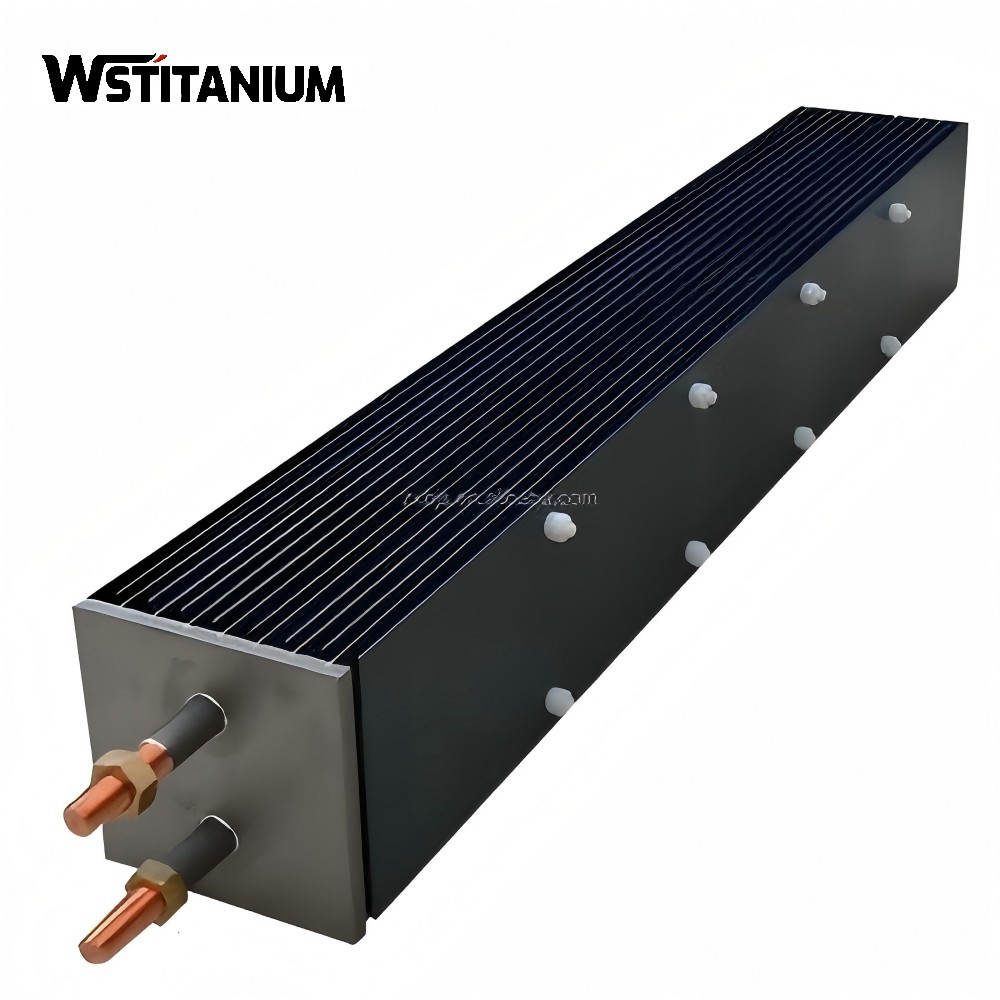

MMO Titanium Anode For Electrolytic Copper

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

In electrolytic copper production, the anode is a critical component that determines electrolytic efficiency, product purity, and environmental performance. The advent of dimensionally stable anodes (DSAs) in the 1960s sparked a technological revolution in the electrolytic industry, with MMO (mixed metal oxide) titanium anodes performing particularly well.

MMO titanium anodes utilize a titanium substrate coated with a composite coating of precious metal oxides, such as ruthenium, iridium, and tantalum, achieving a perfect combination of electrical conductivity, catalytic activity, and corrosion resistance. With advantages such as dimensional stability, low energy consumption, product purity, and long lifespan, MMO titanium anodes have gradually become a preferred option for primary copper production and scrap copper recycling.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

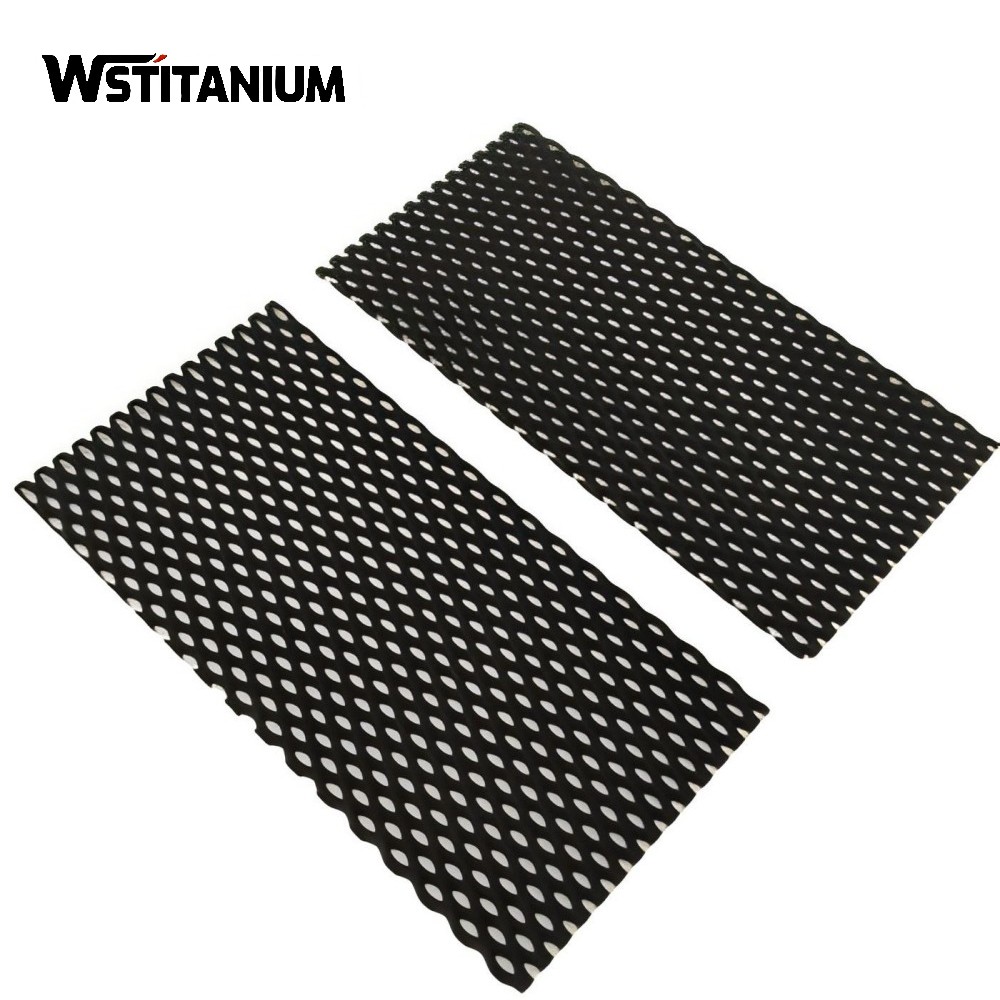

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The application of MMO titanium anodes in copper electrolysis is based on the electrochemical redox principle. The catalytic effect of the coating enhances the anodic reaction while maintaining its structural stability. Copper electrolytic production typically uses a copper sulfate electrolyte system. MMO titanium anodes, as insoluble anodes, primarily undergo the oxygen evolution reaction upon application of power.

Anodic reaction

Water molecules in the electrolyte, catalyzed by the MMO coating, lose electrons at the anode surface to generate oxygen. The reaction equation is: 2H₂O – 4e⁻ → O₂↑ + 4H⁺. Precious metal oxides such as iridium and ruthenium in the MMO coating act as active centers, lowering the activation energy of the reaction, reducing the oxygen evolution overpotential from 1.6-1.8V for lead alloy anodes to 1.4-1.5V (vs. SHE). This catalytic effect not only reduces energy consumption but also acid mist generation. Because the reaction is mild and the bubbles are small and easily detached, acid mist emissions from the electrolytic cell can be reduced by over 30%.

Cathode Reaction

Cu²⁺ in the electrolyte receives electrons on the cathode surface (usually a stainless steel plate or pure copper starter), depositing as metallic copper. The reaction equation is: Cu²⁺ + 2e⁻ → Cu↓. Because the MMO titanium anode is insoluble, impurities are prevented from entering the electrolyte, increasing the purity of the cathode copper from 99.95% to over 99.99%. Furthermore, the stable anode dimensions ensure a constant inter-electrode spacing (fluctuation ≤ ±2%), allowing for uniform Cu²⁺ migration in the electric field and reducing nodular defects on the cathode copper surface.

Charge Transfer Carrier

Efficiently transfers electrons from the external power source to the MMO coating surface. The electronic transition properties of the precious metal oxide facilitate charge transfer. The MMO coating acts as both a catalyst and a physical barrier, preventing direct reaction between the titanium substrate and the strongly acidic electrolyte, achieving “zero-loss” dimensional stability.

Wstitanium’s Advantages

As a professional manufacturer of MMO titanium anodes in China, Wstitanium leverages its comprehensive strengths in material research and development, technological control, and customized services to ensure its products are highly competitive in electrolytic copper production.

(I) Substrate and Coating

The high-purity titanium substrate is treated using pure titanium that meets ASTM B265 Grade 2 standards, with a titanium content of ≥99.8%. A three-step surface treatment process of sandblasting, pickling, and etching achieves a surface roughness of Ra1.5-2.0μm and enhances the coating’s adhesion to over 50MPa. A specialized IrO₂-Ta₂O₅ coating formula is developed, allowing the molar ratio of Ir:Ta to be adjusted (Ir:Ta = 7:3 to 6:4) to accommodate varying current densities. Nanoparticle dispersion technology is employed to maintain a controlled particle size of 50-100nm, increasing the density of catalytic active sites by 40% compared to the industry average. Third-party testing confirmed that the coating’s thickness uniformity error is ≤±0.2μm. Under 1500A/m², the oxygen evolution overpotential remains stable at 1.42V, 80mV lower than standard coatings.

(II) Precision Manufacturing

Automated coating preparation utilizes robotic spraying and step-by-step sintering technology, replacing traditional manual brushing. This allows for coating loading control accuracy of ±0.5g/m². A programmed sintering temperature ramp (room temperature → 300°C → 500°C → 650°C) achieves gradient curing, preventing coating cracking while forming a dense crystal structure, resulting in corrosion resistance over 10 times greater than traditional technologies. Optimized mesh layout and rib width in the mesh anode reduce electrolyte flow resistance by 25% and increase bubble detachment speed by 30%. The inter-electrode spacing can be adjusted with an accuracy of ±0.5mm, effectively reducing the risk of short circuits.

(III) Cost Advantages

Significant energy-saving and environmental benefits. Tested data shows that Wstitanium MMO titanium anodes can reduce cell voltage by 0.2-0.3V and DC power consumption by 15%-20% in electrolytic copper production. For a plant with an annual output of 100,000 tons of electrolytic copper, this translates to annual electricity savings of over 12 million kWh. Environmental treatment costs are also reduced by 40%, complying with EU REACH standards.

Types of MMO Titanium Anodes

The performance of MMO titanium anodes hinges on the precise matching of coating composition and product form. The appropriate type is selected based on the electrolyte system (primarily sulfate-based), current density, and equipment structure.

Iridium-coated titanium anodes

This is the most widely used type of MMO titanium anode in electrolytic copper production. Its core component is IrO₂ (iridium oxide), often doped with Ta₂O₅ (tantalum oxide) to form a composite coating for enhanced stability. Its key advantage lies in its extremely low oxygen evolution overpotential in sulfuric acid systems. At current densities of 1000-3000 A/m², the oxygen evolution overpotential can be reduced by 20%-30% compared to lead alloy anodes. The iridium-tantalum coating offers exceptional chemical stability, providing long-term stable operation in strongly acidic electrolytes with a pH of 0-2. The coating’s annual degradation rate is less than 0.5μm, making it the preferred coating type for high-purity electrolytic copper production.

Ruthenium-iridium-coated titanium anodes

These utilize RuO₂ (ruthenium oxide) and IrO₂ as core components, with their ratio adjusted to achieve a balance between oxygen and chlorine evolution performance. They are suitable for mixed electrolyte systems containing chloride ions (e.g., certain scrap copper recovery technologies). When the Cl⁻ concentration in the electrolyte exceeds 500 mg/L, the ruthenium component preferentially catalyzes the oxidation of Cl⁻ to Cl₂, preventing chloride ion corrosion and contamination of the cathode copper. The iridium component also ensures corrosion resistance in sulfuric acid environments. The current output of this anode ranges from 52-600 mA/m, and the coating consumption rate can be controlled to an extremely low level of ≤6 mg/A·a.

Platinum titanium anodes

These utilize an iridium-tantalum coating with a 1-5 μm thick platinum-group metal modification layer. These anodes exhibit exceptional electrocatalytic activity and chemical stability, making them suitable for the electrolytic production of electronic-grade high-purity copper (purity exceeding 99.999%). It achieves uniform current distribution and avoids nodules on the cathode copper surface. However, due to the high cost of platinum, it is primarily used in high-end precision copper manufacturing.

As a key material for electrolytic copper, the MMO titanium anode, through the synergistic effect of a titanium substrate and a precious metal oxide coating, fundamentally addresses the pain points of traditional lead alloy anodes, such as pollution, high energy consumption, and short lifespan, becoming a core supporting technology for green metallurgy. By reducing the oxygen evolution overpotential, maintaining dimensional stability, and optimizing current distribution, the MMO titanium anode simultaneously improves electrolysis efficiency, product purity, and environmental performance.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt