MMO Titanium Anode For Etching

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Etching, a core technology in electronics manufacturing and precision machining, is widely used in applications such as PCB (printed circuit board) production, semiconductor chips, and precision molding of metal components. Etching fluid, a key medium in this technology, relies on its stable performance to directly determine etching accuracy and efficiency. However, the concentration of metal ions (such as copper and nickel ions) during etching can continuously increase, leading to a decrease in the activity of the etching fluid or even its ineffectiveness. This not only increases costs but also creates environmental pressures due to waste discharge.

After large-scale application of MMO (mixed metal oxide) titanium anodes in various systems, including acidic, alkaline, and micro-etching solutions, the regeneration efficiency of etching fluids has increased by 40%, the copper recovery purity has reached over 99.5%, and the overall production cost has been reduced by 30%.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 95% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The application of MMO titanium anodes in etching solutions revolves around two key objectives: “etching solution regeneration” and “precious metal recovery.” As an insoluble anode, the MMO titanium anode primarily performs electron transfer and catalytic functions in the electrolytic system, and does not participate in the chemical reaction itself. Its operation can be divided into three key steps:

Current Conduction: After connecting to an external power source, the titanium substrate acts as a conductive framework to evenly conduct current to the MMO coating surface. Positive and negative ions in the etching solution migrate in a targeted manner under the influence of the external electric field—cations (such as Cu²⁺) move toward the cathode, and anions (such as Cl⁻ and OH⁻) move toward the anode.

Anodic Catalytic Reaction: Anions reaching the anode undergo an oxidation reaction, the specific reaction type varying with the etching solution system. In acidic etching solutions, chloride ions are oxidized by the ruthenium-iridium coating to produce chlorine gas (2Cl⁻ – 2e⁻ = Cl₂↑). In alkaline and micro-etching solutions, the iridium-tantalum coating catalyzes the oxidation of water molecules or hydroxide ions to produce oxygen (2H₂O – 4e⁻ = O₂↑ + 4H⁺ or 4OH⁻ – 4e⁻ = O₂↑ + 2H₂O).

Etching Solution Regeneration: The anodic reaction adjusts the pH and redox potential of the etching solution, restoring the activity of the spent etching solution. Simultaneously, metal cations in the cathode region gain electrons and are deposited as pure metal (e.g., Cu²⁺ + 2e⁻ = Cu↓), achieving both resource recovery and etching solution recycling.

Etching Solution System

The compositional differences between different types of etching solutions lead to detailed differences in their electrolytic regeneration principles. They can be primarily categorized into three systems: acidic, alkaline, and micro-etching solutions.

Acidic Etching Solutions: The core cause of failure in acidic etching solutions (containing CuCl₂ and HCl) is excessively high Cu²⁺ concentrations. Ion-exchange membrane electrolysis systems using ruthenium-iridium-coated titanium anodes can precisely address this issue. During electrolysis, Cl⁻ oxidizes at the anode to produce Cl₂, which further reacts with water to produce HCl and HClO, replenishing the oxidant in the etching solution. Cu²⁺ is efficiently deposited as pure copper at the cathode. When the Cu²⁺ concentration drops below 50g/L, the etching solution can be regenerated and reused.

Alkaline etching solution: When alkaline etching solution (containing Cu(NH₃)₄Cl₂) becomes ineffective, an iridium-tantalum-coated titanium anode is used for extraction. The oxidation reaction at the anode maintains an alkaline environment, preventing the decomposition of the copper-ammine complex ion. After copper sulfate is separated through extraction, pure copper is deposited at the cathode through the electrolysis system. The regenerated etching solution can be directly returned to the production line, achieving a copper recovery rate exceeding 98%.

Micro-etching solutions: The hydrogen peroxide in the micro-etching solution (Cu₂SO₄ + H₂O₂) is easily degraded. The iridium-tantalum-coated titanium anode first catalytically decomposes excess H₂O₂ in an oxygen-depleting electrolytic cell, eliminating its interference with subsequent electrolysis. Subsequently, in the electrowinning cell, the anode catalyzes oxygen evolution to adjust the solution pH, while the cathode deposits copper metal, achieving simultaneous regeneration of the etching solution and copper recovery.

The long-term, stable operation of the MMO titanium anode relies on the synergistic effect of the coating and the substrate. The titanium substrate’s high corrosion resistance ensures resistance to corrosion in strong acid and alkaline etching solutions, while the crystal structure and composition ratio of the MMO coating determine its electrocatalytic activity and lifespan. Optimizing coating preparation (such as multiple cycles of coating and sintering) can enhance the adhesion between the coating and the substrate, preventing coating flaking at high current densities. Furthermore, the multi-component oxide structure of the MMO coating disperses reaction stress, reduces the formation of a passivation layer, and ensures a stable current efficiency above 90% under continuous operating conditions.

Wstitanium’s Advantages

Wstitanium’s MMO titanium anodes, specifically designed for etching solutions, offer significant competitive advantages in coating technology, structural design, and performance compatibility. Through technological innovation, they have achieved cost reduction, efficiency improvement, and environmental improvements in the etching industry.

(I) Coating Technology

Wstitanium has established a library of customized coating formulas for various etching solution systems. Its core advantage lies in the precise control of coating composition and meticulous preparation.

For acidic etching solutions, a high-ratio ruthenium-iridium composite coating is employed. Nano-scale grain optimization technology reduces the chlorine evolution overpotential to below 1.1V, a 12% reduction compared to the industry average. This reduces energy consumption by over 25% at the same production capacity.

For alkaline and micro-etching solutions, the iridium-tantalum coating developed incorporates rare earth element doping technology, improving the coating’s oxidation resistance by 30%. After three years of continuous operation in alkaline etching solutions at 45°C, the coating wear rate remains below 0.5μm/year.

Utilizing “vacuum spraying + step sintering” technology, coating thickness control accuracy reaches ±0.02μm, ensuring current distribution uniformity within an error of less than 5%. This reduces the thickness error of etched products from the traditional ±5μm to ±1μm, and increases the yield rate to 98%.

(II) Structural Design Capabilities

Based on a deep understanding of etching equipment and technology, Wstitanium has developed comprehensive structural adaptability capabilities:

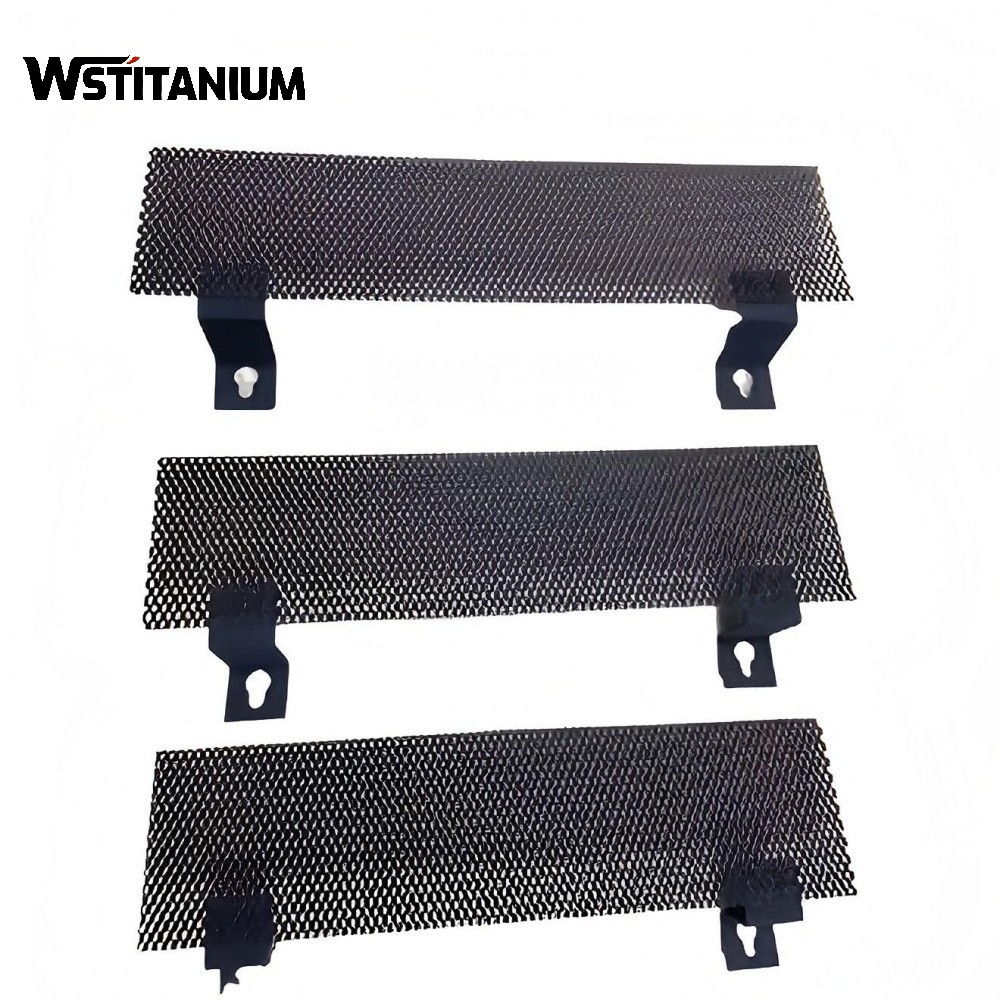

The developed “honeycomb mesh anode” boasts a 50% increase in specific surface area compared to traditional mesh anodes, and a 40% increase in reaction efficiency at the same current density. It is particularly well-suited for the rapid treatment of high-concentration etching waste liquid, with a single unit capable of processing over 50 tons per day.

For small precision etching equipment, we have introduced an ultra-thin plate anode (only 0.8mm thick). Using a lightweight titanium alloy substrate, it is 30% lighter than traditional anodes. Furthermore, its reinforced structural design ensures deformation-free operation at current densities of 1000A/m².

We provide an integrated “anode-cathode” solution, matching the titanium alloy cathode to the characteristics of the etching solution. By optimizing the electrode spacing and surface roughness, we can reduce the electrolytic cell voltage by 0.3-0.5V, further improving energy savings.

(III) Excellent Performance

Wstitanium’s MMO titanium anodes demonstrate outstanding service life and performance stability.

The products have passed accelerated life testing in a 1 mol/L H₂SO₄ solution. At a current density of 500 A/m², the ruthenium-iridium-coated anode has a lifespan of over 3.5 years, while the iridium-tantalum-coated anode has a lifespan of over 4 years. The MMO titanium anode operates stably in etching solutions with temperatures ranging from 20°C to 60°C and current densities ranging from 100 to 3000 A/m². In particular, it maintains a current efficiency exceeding 95% in complex systems with chloride ion concentrations of 5-50 ppm.

As a core material in etching solutions, MMO titanium anodes have driven the development of the etching industry. Through precise coating formulation design, anodes such as ruthenium iridium oxide and iridium tantalum oxide are suitable for acidic, alkaline, and micro-etching solutions, solving the shortcomings of traditional anodes, such as poor corrosion resistance, high energy consumption, and high pollution.

Related products

-

Titanium Fasteners

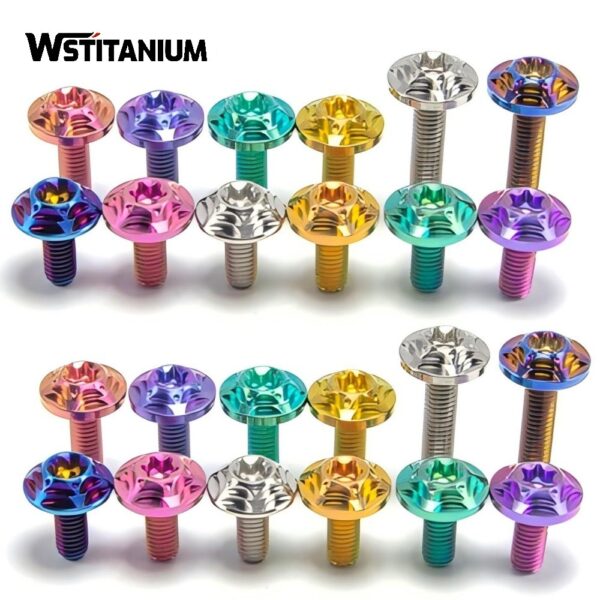

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts