MMO Titanium Anode For Halogenated

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Halides, compounds formed by the combination of halogens such as chlorine, fluorine, and bromine with other elements, are widely present in both industrial and natural environments. Chloride and fluoride ions are characteristic pollutants in many industrial wastewaters. With the rapid development of industries such as pharmaceuticals, pesticides, textiles, and electroplating, the discharge of halide-containing wastewater continues to increase, making its treatment difficult and the environmental risks increasingly prominent.

Mixed metal oxide titanium anodes (MMO titanium anodes), as highly efficient electrochemical materials, demonstrate irreplaceable advantages in halide treatment, leveraging the excellent corrosion resistance of their titanium substrate and the high catalytic activity of their precious metal oxide coating.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Halide Pollution

The generation of halides is closely related to industrial production. Halogenated raw materials such as chlorinated hydrocarbons and fluorinated benzenes are required in the synthesis of products such as herbicides and antibiotics. The resulting wastewater carries large amounts of organic and inorganic halide ions. Chloride is often used as an electrolyte and chelating agent in electroplating. Semiconductor manufacturing requires fluorinated etching solutions, resulting in wastewater containing not only high concentrations of chloride and fluoride ions, but also heavy metal ion contamination. Textile bleaching relies on chlorine-containing agents such as sodium hypochlorite. Fluorite mining and aluminum electrolysis generate fluoride-containing wastewater, while non-ferrous metal smelting discharges acidic wastewater containing chlorine and bromine.

Ecotoxicity: Organic halides, such as polychlorinated biphenyls (PCBs), are highly teratogenic and carcinogenic and can accumulate through the food chain, posing a long-term threat to aquatic life and human health. High concentrations of fluoride ions can cause soil salinization and impair plant root absorption.

Water Quality: Excessive chloride ions in drinking water can affect taste, while excessive fluoride ions can cause bone diseases. The presence of halogenated disinfection byproducts has become a significant safety risk for drinking water.

Corrosion: High concentrations of halides in industrial circulating water can exacerbate equipment corrosion. For example, chloride ions can damage the passivation film on metal surfaces, shortening the service life of equipment such as heat exchangers by more than 50%.

Working Principle of the MMO Titanium Anode

The MMO titanium anode degrades and converts halides through electrochemical oxidation. The MMO titanium anode utilizes a composite structure of a titanium substrate and a mixed metal oxide coating. The titanium substrate is made of Gr1 titanium that complies with ASTM B-265, which is resistant to corrosion in most acidic and alkaline media. The surface coating of precious metal oxides such as iridium, ruthenium, and tantalum serves as an active and conductive layer, efficiently conducting current from an external DC power supply to the electrode surface, providing energy for the electrochemical reaction. Two main types of oxidation reactions occur on the surface of the MMO titanium anode:

Targeted Conversion of Inorganic Halide Ions: For chloride ions, an oxidation reaction occurs at the anode: 2Cl⁻ – 2e⁻ = Cl₂↑. The generated chlorine gas is further converted into active chlorine species such as hypochlorous acid (HClO) in aqueous solution. These active species not only have a disinfecting effect but can also be further activated into hydroxyl radicals (・OH), which have stronger oxidizing power. For difficult-to-oxidize halide ions such as fluoride, adjusting the electrode potential can promote their co-precipitation with other ions.

Degradation and mineralization of organic halides: The MMO anode degrades organic halides through both direct and indirect oxidation pathways. Direct oxidation occurs when organic halides lose electrons at the anode surface, breaking bonds and generating low-toxic intermediates. Indirect oxidation occurs when strong oxidizing substances such as active chlorine and hydroxyl radicals generated at the anode attack the carbon-halogen bonds of organic halides, ultimately mineralizing them into CO₂, H₂O, and inorganic halide ions.

MMO Titanium Anode Types

Based on the type of halide, wastewater properties, and application scenarios, MMO titanium anodes can be divided into the following four categories.

(I) Ruthenium-Iridium MMO Titanium Anodes

This type of anode uses ruthenium oxide (RuO₂) as the primary active component and iridium oxide (IrO₂) as a secondary component. It exhibits excellent chlorine evolution catalytic activity and is the preferred electrode for treating chlorinated wastewater. The coating is prepared by thermal decomposition, and the ruthenium-iridium ratio can be adjusted according to the chloride ion concentration. In acidic chlorinated wastewater, it exhibits an extremely low chlorine evolution overpotential and a current efficiency exceeding 90%. It is suitable for applications such as electroplating wastewater dechlorination, sodium hypochlorite generators, and the degradation of chlorinated organic wastewater. At a current density of 300A/m², it has a service life of 5-8 years.

(2) Iridium-Tantalum MMO Titanium Anode

The core coating consists of iridium oxide (IrO₂) and tantalum oxide (Ta₂O₅). The tantalum oxide strengthens the coating’s bond to the substrate and improves corrosion resistance. This type of electrode exhibits a high oxidation potential and excellent stability in highly acidic, high-salinity halide wastewaters. It is particularly suitable for treating mixed halide wastewaters containing fluorine and chlorine. Typical applications include the treatment of fluorine-containing wastewater in semiconductors and the degradation of highly acidic, halide-containing wastewater in the chemical industry. The coating thickness is typically controlled at above 6g/m² and can withstand high current densities exceeding 1000A/m².

(3) Multi-element Composite Coating MMO Titanium Anode

For halide wastewaters with complex compositions, a quaternary composite coating of iridium, ruthenium, tantalum, and titanium is used. Performance is optimized by adjusting the ratio of the components. For example, increasing the iridium content enhances corrosion resistance, while increasing the ruthenium content improves catalytic activity. This electrode is suitable for treating mixed halide wastewater in industries such as pharmaceuticals and pesticides. It can simultaneously degrade organic halides and convert inorganic halide ions. In high-load wastewater with COD concentrations exceeding 5000 mg/L, its treatment efficiency is 2-5 times that of conventional electrodes.

(IV) Special Structure MMO Titanium Anode

Depending on the needs of the treatment equipment, it can be manufactured into special structures such as tubular, mesh, and flexible.

MMO Titanium Tube Anode: Featuring a large specific surface area, it is suitable for deep well treatment systems and widely used in chemical park tank corrosion protection and halide wastewater treatment. It is resistant to corrosion from a variety of corrosive media.

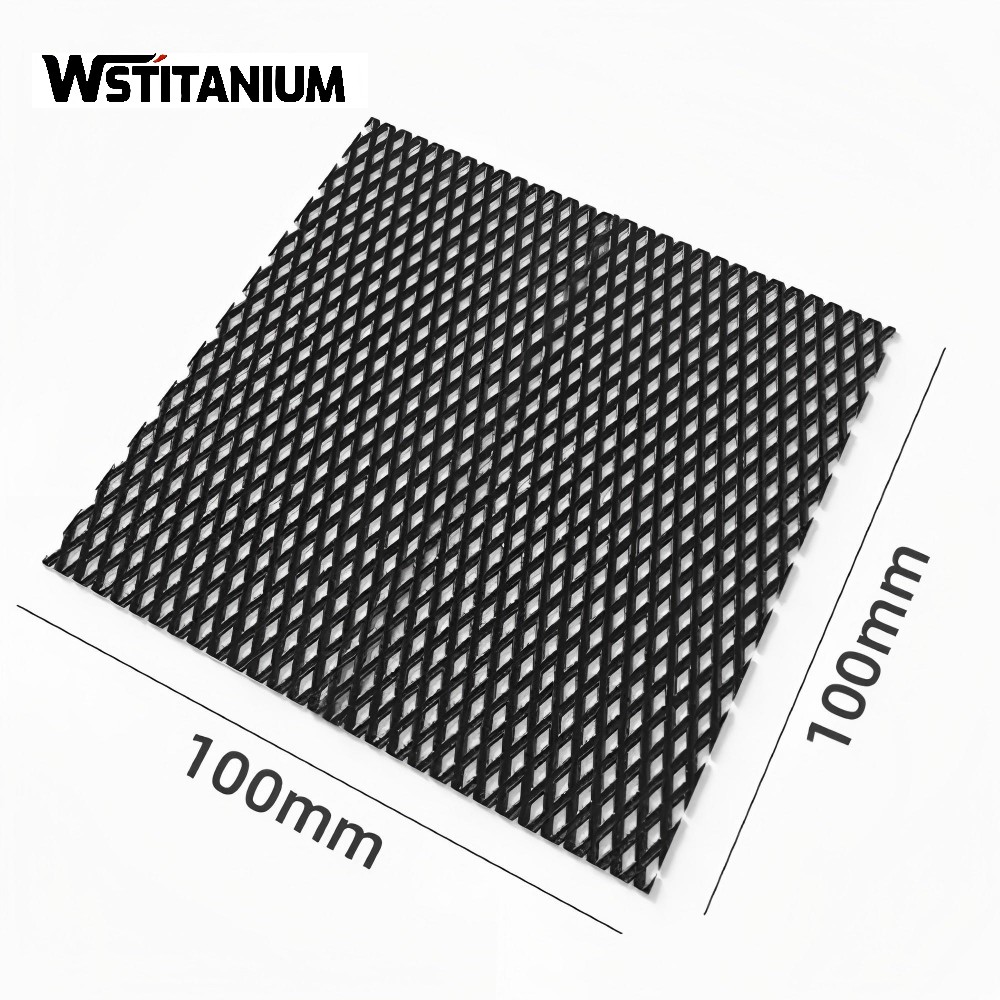

MMO Titanium Mesh Anode: Providing uniform current distribution, it is suitable for halide degradation within electrolytic cells. The pore size and thickness can be customized to suit the cell size to optimize conductivity.

Flexible MMO Titanium Anode: Using a thin titanium strip substrate, it can be installed in complex terrain. It is primarily used for soil halide contamination remediation and groundwater dehalogenation.

Wstitanium has established a database of coatings tailored to different halide types, enabling precise matching of optimal formulations based on wastewater composition. High-ruthenium-to-iridium ratio coatings are used for high-chloride wastewater, while the iridium-tantalum ratio is optimized for fluoride-containing wastewater. Multi-component composite coatings are developed for mixed halide wastewater. Precise control of precious metal content (30-80 g/m²) and coating thickness ensures a balance between catalytic activity and corrosion resistance under specific electrode operating conditions. The titanium substrate undergoes seven pretreatment steps, including sandblasting and pickling, to ensure a coating adhesion of ≥35 MPa. Micro-spraying technology is used to achieve uniform coating application, with a thickness tolerance within ±0.5 g/m². Gradient sintering at 500-550°C creates a dense and stable oxide crystal structure.

Related products

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs