MMO Titanium Anode For Sulfur

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Sulfides, a critical industrial substance, are widely present in core industries such as mining, petrochemicals, and textile printing and dyeing. Untreated sulfide emissions have become a major source of global water and air pollution.

Mixed Metal Oxide Titanium Anodes (MMO Titanium Anodes), a next-generation dimensionally stable anode (DSA), utilize a commercially pure titanium substrate coated with precious metal oxides such as ruthenium, iridium, and tantalum to create a highly efficient catalytic system. Leveraging its core advantages of high electrocatalytic activity, excellent corrosion resistance, and long-term stability, they demonstrate exceptional performance in sulfide pollution treatment.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Sulfide Pollution

Sulfide and its derivatives are used across multiple industrial sectors, forming a diversified application system centered on the chemical industry. Sulfiding agents such as sodium sulfide are required in the flotation and hydrometallurgy of non-ferrous metal sulfide ores (such as copper, zinc, and lead). Ore decomposition also releases large amounts of sulfide, and the resulting slurry wastewater is a major source of sulfide pollution. Organic sulfides (such as mercaptans and sulfides) contained in crude oil must be removed through desulfurization during refining. The resulting sulfur-containing wastewater and hydrogen sulfide waste gas treatment fluid constitute high-concentration pollution sources. Sulfide pollution, primarily carried by wastewater and waste gas, exhibits the typical characteristics of high toxicity, rapid transformation, and widespread harm.

Severe Toxicity: Sulfide can transform into sulfur dioxide, sulphur dioxide, and hydrogen sulfide (H₂S) under varying pH conditions. Hydrogen sulfide is a highly toxic gas. Airborne concentrations exceeding 10 mg/m³ are irritating to humans, and concentrations exceeding 1000 mg/m³ can be instantly fatal. Sulfide in wastewater can cause suffocation and death to aquatic organisms, and even fish can be affected at concentrations as low as 0.5 mg/L.

Corrosion: Sulfide is easily converted into hydrogen sulfide by microorganisms in anaerobic environments, which escapes into the atmosphere and causes foul odor pollution. Sulfide also reacts with metal equipment to form sulfide precipitates, leading to corrosion and perforation of pipes and reactors.

Wide-range pollution: Discharge of sulfur-containing wastewater rapidly reduces dissolved oxygen in the water, creating an anaerobic environment that causes the water to become dark and odorous, impacting aquatic ecosystems. Organic sulfides are bioaccumulative, accumulating through the food chain and ultimately endangering human health. Furthermore, complex working conditions such as high salt content and strong acidity further complicate sulfide control.

Working Principle of the MMO Titanium Anode

The MMO titanium anode achieves efficient degradation and conversion of sulfides through electrochemical oxidation. The coating’s catalytic active sites disrupt the stable chemical structure of sulfides, converting them into harmless or low-toxic substances.

(I) Direct Oxidation

Under the influence of an external DC power source, when sulfur-containing wastewater contacts the anode surface, sulfides (S²⁻, HS⁻) diffuse and adsorb onto the active sites of the MMO coating, resulting in a direct electron transfer reaction. Strongly adsorbed hydroxyl radicals (・OH) generated on the anode surface attack the S-H and S-S bonds of the sulfides, first oxidizing them to elemental sulfur (S⁰), then further to sulfite (SO₃²⁻), and ultimately to harmless sulfate (SO₄²⁻). The low overpotential of the MMO coating effectively suppresses the oxygen evolution side reaction, allowing more electrons to be used for sulfide oxidation, thereby increasing current efficiency to over 90%.

(II) Indirect Oxidation

Based on the water quality characteristics of sulfur-containing wastewater, indirect oxidation pathways can be divided into two main types:

Chlorine-based oxidation system: For high-salinity, chlorine-containing, and sulfur-containing wastewater, the chlorine evolution reaction (2Cl⁻ – 2e⁻ = Cl₂↑) preferentially occurs on the MMO anode surface. The generated chlorine gas rapidly reacts with water to form hypochlorous acid (HClO). As a strong oxidant, hypochlorous acid efficiently oxidizes sulfides, especially for low-concentration organic sulfides, with a reaction rate more than three times higher than direct oxidation.

Oxygen-based oxidation system: In a chlorine-free or low-chlorine environment, the oxygen evolution reaction (4OH⁻ – 4e⁻ = O₂↑ + 2H₂O) occurs at the anode. The generated reactive oxygen species (such as O₃ and ・O₂⁻) then oxidize sulfides. By manipulating the coating composition (e.g., increasing the iridium content), the oxygen evolution potential at the anode can be increased, promoting the generation of strong oxidizing free radicals and enhancing the ability to destroy recalcitrant organic sulfides.

MMO Titanium Anode Types

Targeting the diverse characteristics of sulfur-containing wastewater (such as concentration, pH, salinity, and presence of heavy metals), MMO titanium anodes are available in a variety of specialized types through differentiated coating compositions and structural designs.

Ruthenium-Iridium Anodes: With RuO₂-IrO₂ as the core active component, these anodes are chlorine-evolving anodes. These anodes can increase chlorine evolution efficiency by over 30% in chlorine-containing environments, rapidly generating hypochlorous acid to degrade sulfides. They are particularly suitable for treating high-salinity, sulfur-containing wastewater generated by petrochemicals and power plants.

Iridium-Tantalum Anodes: With IrO₂-Ta₂O₅ as the primary coating components, these anodes are highly stable oxygen-evolving anodes. The addition of tantalum oxide significantly enhances the coating’s acid corrosion and oxidation resistance, enabling direct oxidation and degradation of high-concentration inorganic sulfides through the generation of a high oxygen potential. These anodes are suitable for treating acidic, sulfur-containing wastewater generated by mineral processing and hydrometallurgy. The oxygen evolution potential can be controlled below 1.40V.

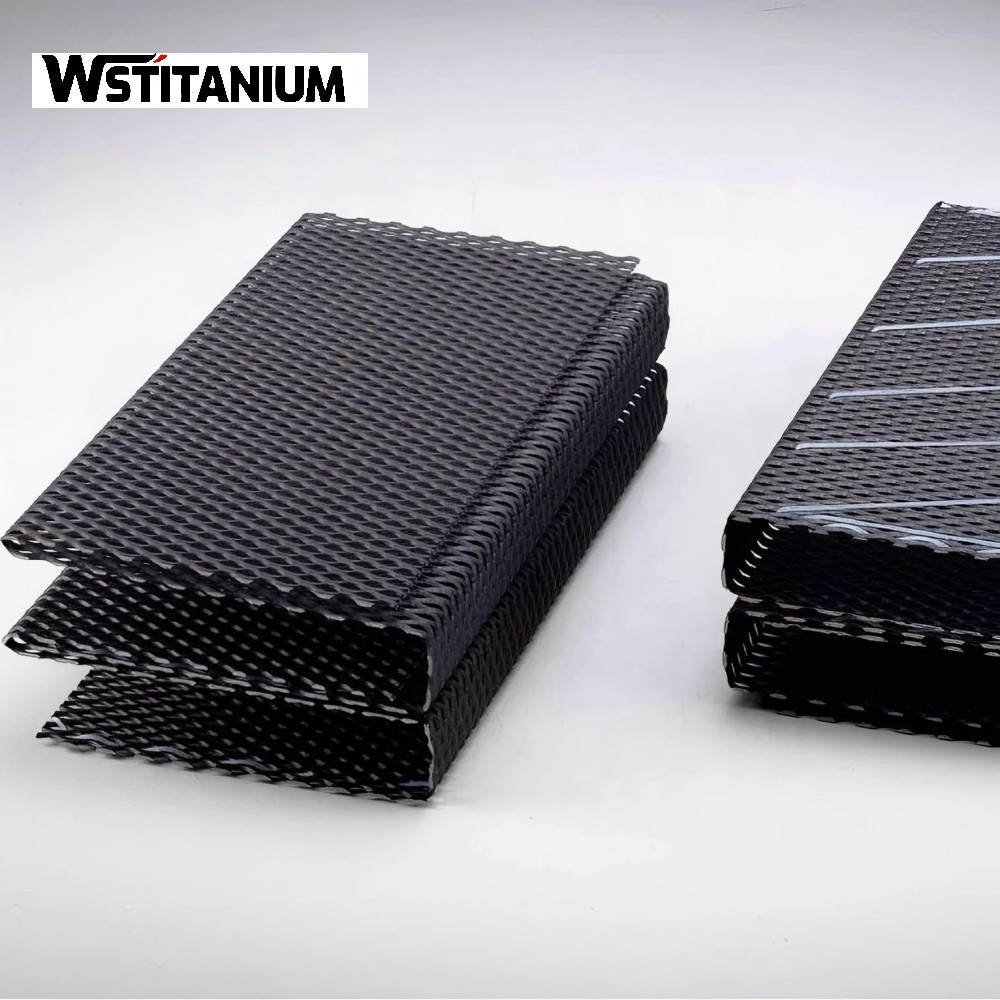

Mesh MMO titanium anodes: Utilizing a three-dimensional mesh structure, they offer a porosity of 60%-80% and a specific surface area 3-5 times greater than flat electrodes. They are suitable for treating low- and medium-concentration sulfur-containing wastewater.

Tubular MMO titanium anodes: Featuring a hollow tubular structure, they offer strong pollution resistance and flexible installation, allowing them to be directly inserted into reactors or deep wells to treat high-concentration sulfur-containing wastewater. Their outstanding corrosion resistance makes them widely used in emergency wastewater treatment around sulfur-containing storage tanks. They withstand corrosion from a variety of chemical media and provide stable current output.

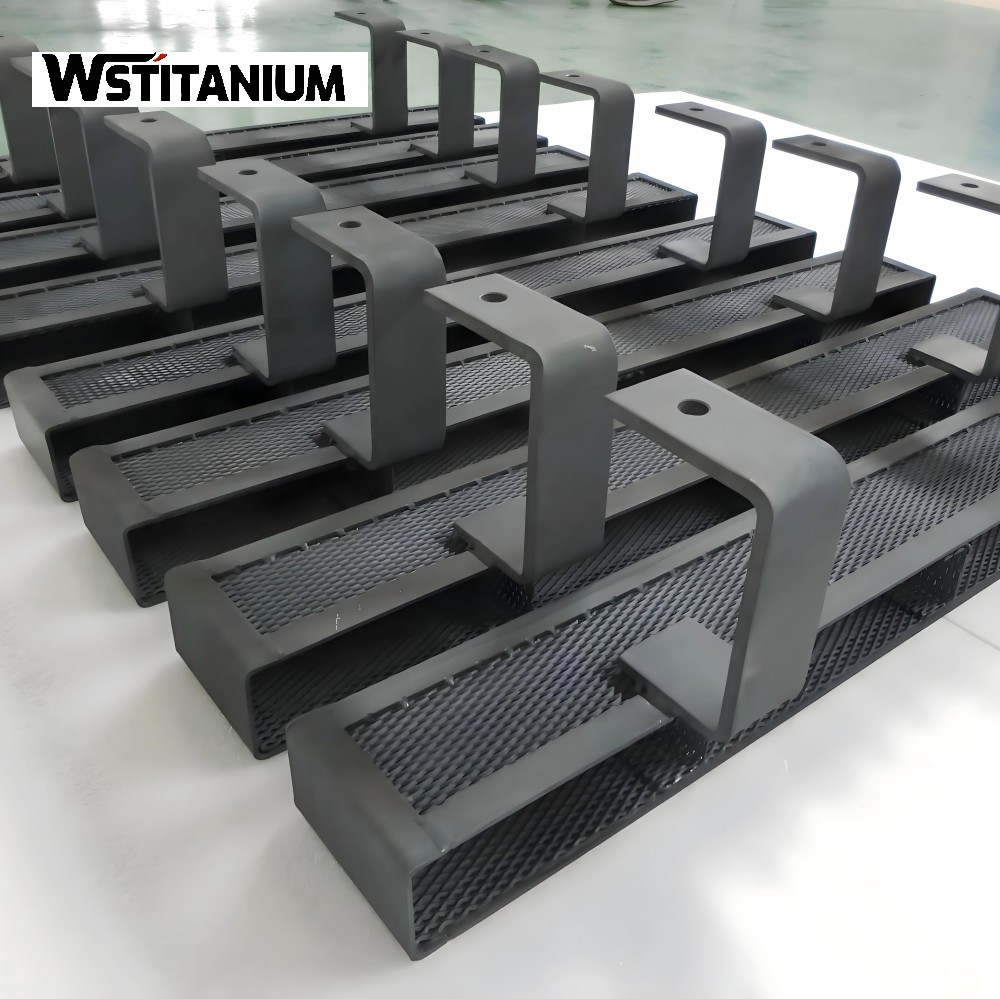

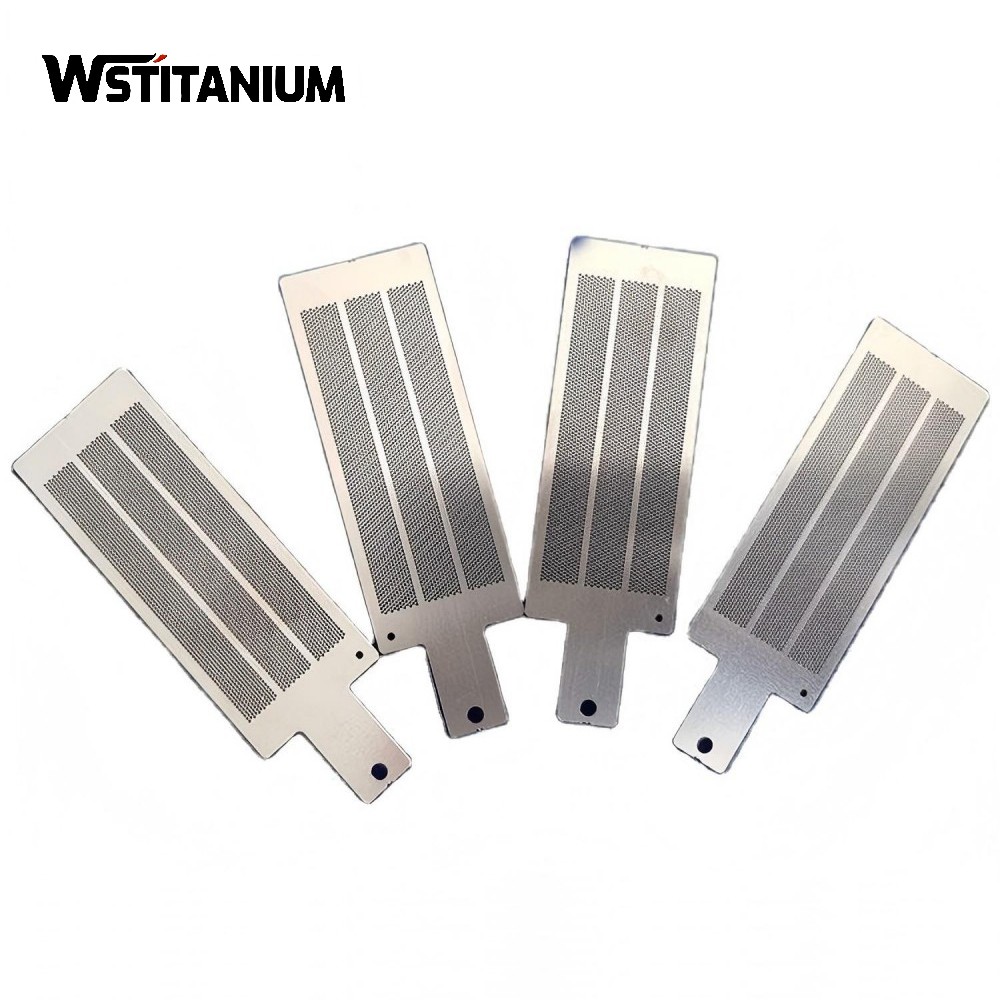

Plate MMO titanium anodes: Featuring a flat plate structure, they are simple to manufacture and maintain, making them suitable for miniaturized sulfur-containing wastewater treatment equipment. Multiple plates can be combined to adjust the reaction area to meet varying treatment capacity requirements. However, their disadvantage is relatively low mass transfer efficiency, requiring a stirring device to improve reaction uniformity.

The selection of MMO titanium anodes must be based on water quality analysis: Ruthenium-iridium mesh anodes are preferred for high-salinity, chlorine-containing, and sulfur-containing wastewater; iridium-tantalum tubular or plate anodes should be used for strong acid, non-chlorine-containing, and sulfur-containing wastewater; and titanium dioxide-modified coating anodes are required for high-concentration, refractory organic sulfur-containing wastewater. Treatment capacity, energy budget, and equipment space must also be comprehensively considered to achieve a balance between technical adaptability and economic rationality. For example, a petrochemical company reduced treatment costs by 40% compared to traditional technologies after selecting ruthenium-iridium mesh anodes for chlorine-containing and sulfur-containing wastewater.

Related products

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt