MMO Titanium Anode Manufacturer

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

In electrochemical technology, MMO titanium anodes (titanium-based metal oxide-coated anodes) serve as core functional components, their performance directly determining the efficiency, lifespan, and economic viability of electrochemical systems. This electrode material, constructed from a base of industrially pure titanium and coated with a composite coating of precious metal oxides such as ruthenium, iridium, and platinum, has completely replaced traditional electrodes such as graphite and lead alloys due to its superior corrosion resistance, high catalytic activity, and dimensional stability. It has become an indispensable key material in the chlor-alkali industry, cathodic protection, and wastewater treatment.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

MMO Titanium Anode Manufacturing

The manufacturing of MMO titanium anodes is a fusion of materials science and precision technology. High-quality manufacturers must possess three core capabilities: substrate control, coating expertise, and precision machining.

(I) Substrate

Substrate quality and pretreatment are fundamental to electrode performance, directly impacting coating adhesion and overall lifespan. Wstitanium uses ASTM B 265 Gr1/Gr2 commercially pure titanium as its substrate. Gr1 pure titanium, with a titanium content of ≥99.5% and low susceptibility to hydrogen embrittlement, is particularly suitable for harsh corrosive environments. The substrate flatness tolerance is controlled within ±0.1mm/m. For precision machining, Wstitanium utilizes high-precision CNC cutting and punching technology to achieve precise processing from 0.5mm thin to 6mm thick plates, resulting in burr-free and oxidation-free cuts.

Wstitanium employs a three-step pretreatment process: sandblasting, pickling, and passivation. 120-180 mesh white corundum sand is used for sandblasting. Sandblasting: Automated equipment controls the sandblasting pressure (0.4-0.6 MPa) and angle (45°) to create a uniformly roughened surface with a Ra of 1.5-3.0 μm, increasing the specific surface area by more than three times compared to the original surface.

Acid Washing: A 10% oxalic acid solution (constant temperature: 80°C) is used for 30-40 minutes to thoroughly remove the surface oxide layer and sandblasting residue.

Passivation: Low-temperature oxidation at 200°C forms a dense TiO₂ transition layer, increasing the coating’s adhesion to over 50 N/cm, far exceeding the industry average of 30 N/cm. The pre-treated substrate undergoes 100% roughness testing with a roughness meter. Only when the roughness is within the 3-10 μm range can it proceed to the next step.

(II) Coating System

The coating is the core of the MMO titanium anode. Its formulation and preparation technology directly determine its catalytic activity and corrosion resistance. Leading manufacturers in the development of customized coating formulations have established coating systems covering a full range of application scenarios. These systems are categorized into three main categories based on their reaction characteristics:

Chlorine-evolving coatings: These utilize RuO₂ as the core, combined with IrO₂ and TiO₂ to form a composite system. Their chlorine evolution potential is ≤1.36V (vs. SHE), making them suitable for chlorine-containing applications such as the chlor-alkali industry and seawater disinfection. RuO₂ content should be 30%-50% to ensure catalytic efficiency.

Oxygen-evolving coatings: These utilize IrO₂ as the primary active ingredient, doped with Ta₂O₅ for enhanced stability. Their oxygen overpotential is controlled between 1.8-2.0V, making them suitable for applications such as wastewater treatment and water electrolysis. The addition of Ta₂O₅ improves the coating’s wear resistance by 40%.

Specialty coatings include titanium dioxide composite coatings and platinum-group metal-modified coatings. The former operates stably in extreme pH environments of 0-14, while the latter is suitable for high-precision electrochemical synthesis. Professional manufacturers can customize specific formulations based on customer parameters such as water quality and current density by adjusting the ratio of precious metals and doping elements. For example, for high-salt wastewater, the Ta₂O₅ content can be increased to 40% to enhance salt corrosion resistance.

High-precision coatings require a multi-pass coating-gradient sintering process, where Wstitanium achieves micron-level precision control:

Coating: Automated spraying equipment is used to evenly apply the coating slurry to the substrate surface, controlling the thickness of each pass to 2-3μm. This ensures a coating uniformity deviation of less than ±0.5μm, eliminating the uneven thickness problems associated with manual coating.

Sintering: A tunnel-type sintering furnace is used, with a gradient temperature profile set at 300°C preheating, 450°C sintering, and 500°C holding. Each sintering pass is precisely controlled within 15-20 minutes, ensuring a dense crystalline structure while preventing substrate deformation due to high temperatures.

Quality Inspection: Each batch of products must undergo linear sweep voltammetry to test oxygen/chlorine evolution potential (deviation <±0.02V). Coating adhesion is tested using the cross-hatch method to ensure no peeling.

(III) Anode Shape Customization

Anode shape directly impacts the mass transfer efficiency and spatial adaptability of the electrochemical system. Wstitanium offers full customization capabilities to meet the needs of diverse equipment structures.

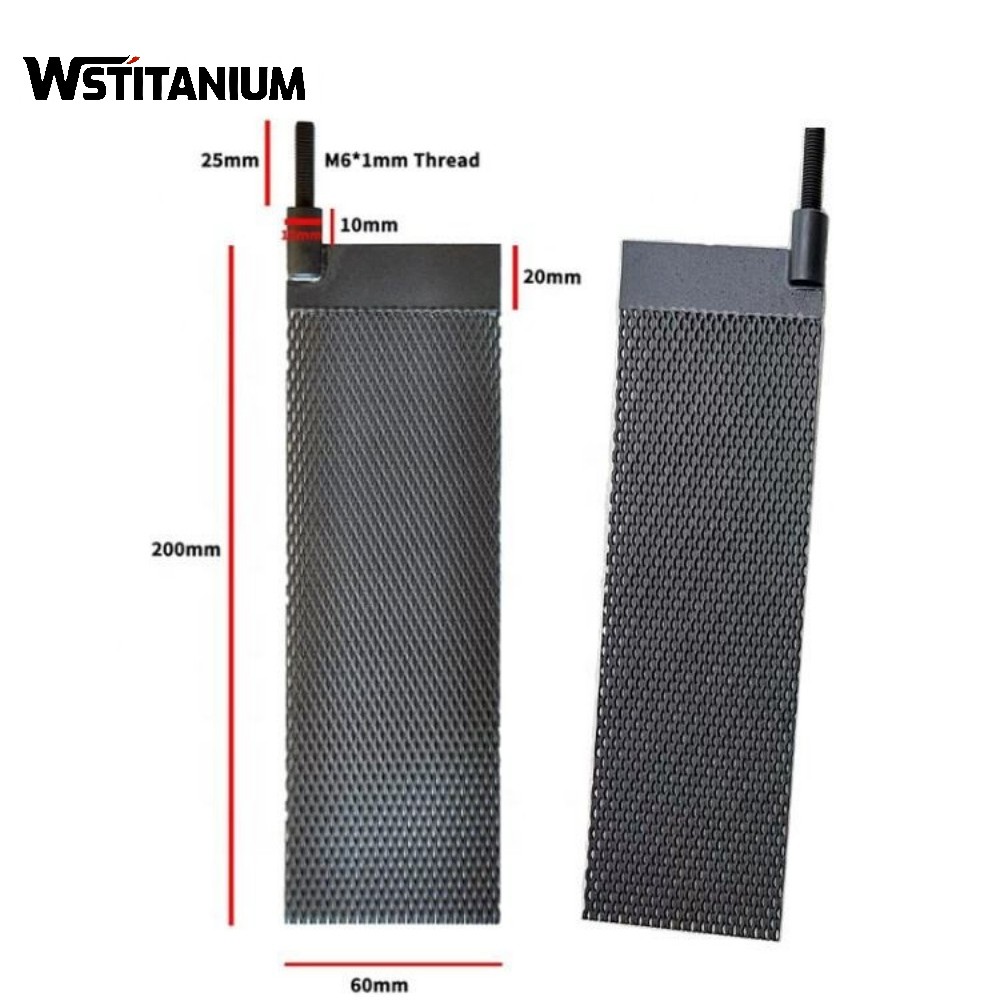

Mesh Anode: Woven from titanium wire, with a porosity of 60%-80%, this anode boasts a surface area 3-5 times greater than flat electrodes. It is suitable for open electrolytic cells and effectively reduces the “bubble shielding effect.” Wstitanium customizes mesh specifications (e.g., 12.7×4.5mm, 6×3mm) and reinforces the mesh surface through welding to ensure a smooth surface.

Tubular/Rod Anode: Crafted from seamless titanium tubes or drawn titanium rods, tubular anodes create turbulent flow, increasing mass transfer efficiency by 40% compared to plate-type anodes. They are suitable for pipeline processing and deep well systems, and can be customized to lengths exceeding 10 meters.

Plate/Sheet Anodes: Thickness 0.5-6mm, available in rectangular, circular, and other shapes, suitable for small and medium-sized electrolytic cells. Surface flatness tolerance within ±0.2mm.

Strip Anodes: Width 6.35-50mm, roll lengths up to 152.4 meters. Suitable for tank corrosion protection. Laying in concentric circles ensures uniform potential distribution (fluctuation within ±0.1V).

Special-Shaped Anodes: Customizable to the internal dimensions of the equipment, such as curved and polygonal anodes, suitable for reactors and special-shaped electrolytic cells. 3D modeling and CNC machining are required to ensure a perfect fit.

Integrated Anodes: The anode, conductive rod, and connector are integrated into a single unit, using titanium threaded or welded connectors. The connectors are fully coated and have a contact resistance of ≤0.01Ω, preventing energy loss due to connection issues.

MMO titanium anodes have become a core component of industrial electrolysis, cathodic protection, and environmental management. The diverse performance requirements of different fields further highlight the importance of manufacturers’ technical reserves and customization capabilities. Wstitanium ensures product reliability through a comprehensive quality control system, overcomes performance bottlenecks with patented coating technology, adapts to diverse scenarios through full-form customization, and optimizes customer costs through full lifecycle services, thus establishing an irreplaceable competitive advantage.

The performance of MMO titanium anodes is highly dependent on the comprehensive capabilities of the manufacturer, from the stringent standards for substrate selection to the precise control of coating formulations and final molding. Each step demonstrates technical strength and a commitment to quality. High-quality manufacturers are not merely “producers” but also “solution providers,” creating value for customers beyond the product itself through customization and comprehensive service.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Burnt Titanium Wheel Bolt