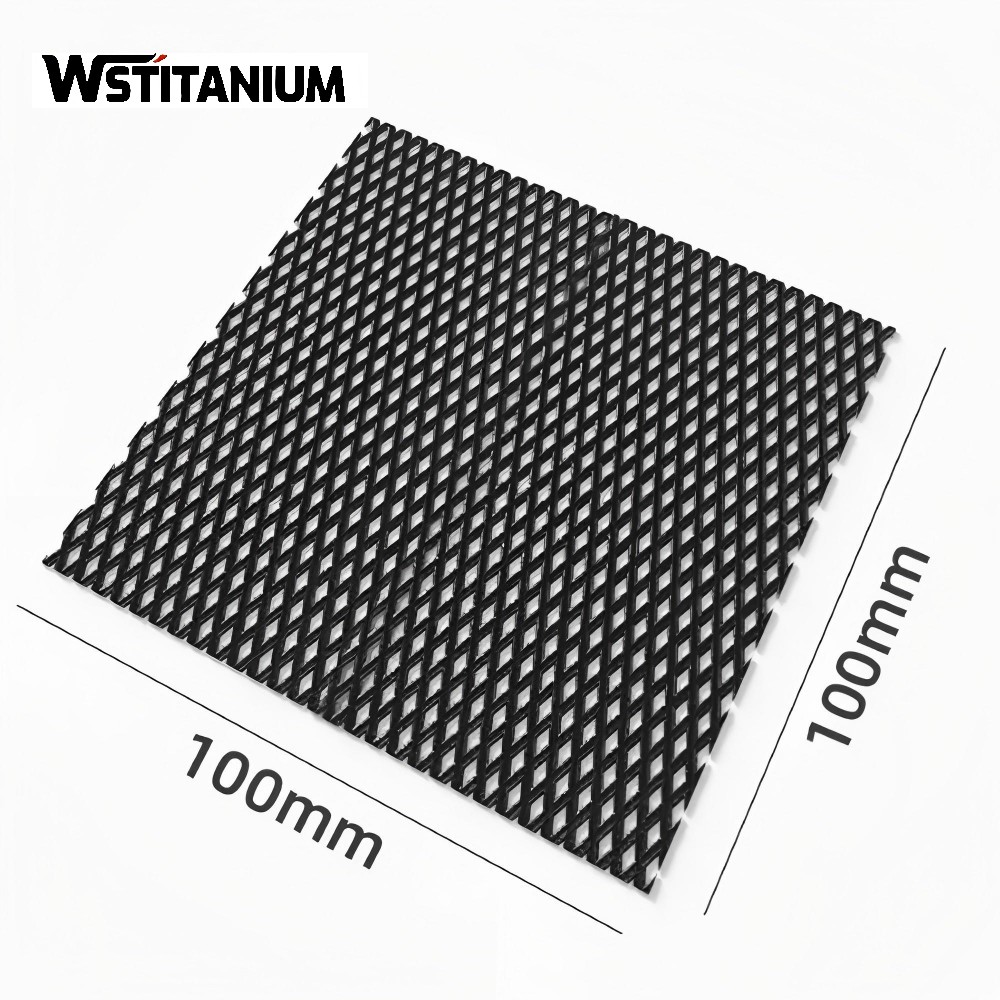

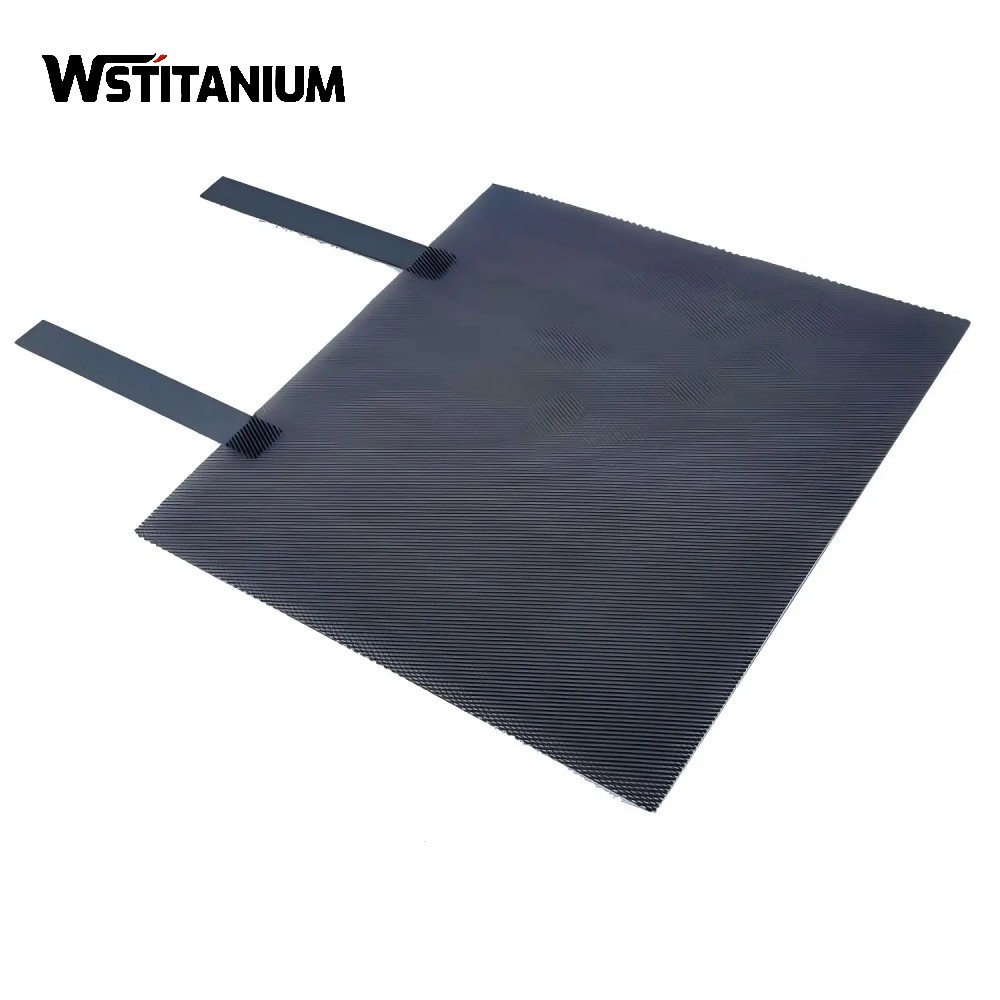

MMO Titanium Anode Mesh

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Mesh MMO titanium anode (titanium-based metal oxide-coated mesh anode), a key member of the dimensionally stable anode (DSA) family, is increasingly popular in the electrochemical field due to its unique structural design and outstanding performance.

MMO titanium anodes utilize a base of commercially pure titanium, coated with precious metal oxides such as ruthenium, iridium, and tantalum. This creates a mesh titanium substrate with high conductivity, strong catalytic activity, and excellent corrosion resistance. Its core advantage lies in the perfect fusion of the structural stability of titanium with the catalytic properties of precious metal oxides. Furthermore, the high porosity of the mesh structure significantly improves electrochemical reaction efficiency.

From large-scale production in the chlor-alkali industry to micron-scale machining in precision electroplating, from advanced industrial wastewater treatment to cathodic protection of large steel structures, mesh MMO titanium anodes have become indispensable core components in a wide range of fields.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of Mesh MMO Titanium Anodes

The specification system for mesh MMO titanium anodes is structured around three core dimensions: substrate properties, coating parameters, and structural dimensions. Different specifications can be combined to precisely match diverse operating requirements.

(I) Substrate Specifications

The substrate, as the structural foundation of the electrode, directly determines the anode’s mechanical strength and corrosion resistance. Currently, the mainstream material is industrially pure titanium that meets the ASTM B265Gr1 standard.

The titanium mesh substrate typically has a thickness range of 0.6-0.89mm, which can be extended to 0.3-2.0mm for special applications. The mesh size is rectangular or square, with standard specifications ranging from 2.5×4.6mm to 25×50mm. Porosity can reach 60%-80%, ensuring smooth electrolyte flow and providing ample reaction area. The substrate length can be customized to meet equipment requirements, up to 76m, and widths ranging from 10mm to 1220mm, meeting diverse installation requirements from small electrolytic cells to large cathodic protection systems.

(II) Coating Specifications

The coating is the core of the catalytic function of the mesh MMO titanium anode. Its formulation and parameters directly determine the electrode’s electrochemical performance. The chlorine evolution system utilizes a RuO₂-IrO₂ composite oxide, suitable for chlorine-containing environments such as the chlor-alkali industry. The oxygen evolution system utilizes an IrO₂-Ta₂O₅ mixed oxide, suitable for applications such as sulfate electrolysis. For specialized high-precision applications, a platinum group metal modification layer is used to further enhance catalytic stability.

Key technical parameters of the coating are strictly controlled: thickness must be greater than 2.0 microns to ensure a complete protective and catalytic layer; crystal density is controlled between 6-12 g/cm³, and coating resistance is maintained between 9-11 microhms/cm to ensure excellent conductivity and catalytic activity.

(III) Electrochemical Performance

Electrochemical performance is a core indicator of anode practicality, primarily encompassing current carrying capacity, potential characteristics, and lifespan. In terms of current density, this anode can withstand transient surges up to 10,000 A/m², and long-term operation is recommended to be controlled at ≤5,000 A/m². The linear current output varies between 1.32 and 23.1 mA/m² for different models.

Potential characteristics vary depending on the coating formulation. The chlorine evolution overpotential in chlorine evolution systems is ≤1.36V (vs. SHE), while the overpotential in oxygen evolution systems is 20%-30% lower than that of traditional electrodes, significantly reducing cell voltage and energy consumption. In terms of lifespan, at a rated current of 110 mA/m², the standard product has a lifespan of over 100 years, and under industrial high-intensity electrolysis conditions, it can reach 5-7 years. The titanium substrate can be re-coated 3-5 times, extending its lifespan.

(IV) Environmental Adaptability

The mesh MMO titanium anode boasts exceptional environmental adaptability, with specifications designed to fully address the stringent requirements of diverse operating conditions. Its acid and alkaline resistance covers the full pH range of 0-14, enabling stable operation in extreme acid and alkaline environments such as concentrated sulfuric acid and caustic soda. Its salt tolerance has been validated in desalination applications, withstanding Cl⁻ concentrations exceeding 300g/L. It also boasts short-term temperature resistance of up to 80°C, and can withstand even higher temperatures through coating enhancement.

Advantages of the Mesh MMO Titanium Anode

The mesh MMO titanium anode offers comprehensive advantages in structural design, performance, and overall cost, specifically reflected in the following five aspects:

(I) Mesh Structure

The mesh structure’s high porosity (60%-80%) increases its specific surface area by 3-5 times compared to planar electrodes, significantly enhancing the electrolyte’s mass transfer efficiency and the reaction contact area. This allows for more complete electrochemical reactions. Under equivalent current conditions, the reaction rate is increased by over 40% compared to conventional electrodes. Furthermore, the mesh structure’s fluidity prevents the accumulation of reaction products on the electrode surface, reducing polarization and ensuring more stable and efficient electrolysis.

(II) Dimensional Stability

The titanium substrate achieves zero losses during electrolysis. Cell voltage fluctuations are controlled within ±2%. Because the precious metal oxide coating reduces the reaction overpotential, the operating voltage is 10%-20% lower than that of graphite anodes, improving the overall energy efficiency of the electrolysis system by 15%-25%. Taking the chlor-alkali industry as an example, the use of this anode can reduce DC power consumption by 200-300 kWh per ton of caustic soda.

(III) Superior Corrosion Resistance

The titanium substrate and precious metal oxide coating form a synergistic protective system, endowing the anode with exceptional corrosion resistance. In highly corrosive environments such as those containing chlorine and fluorine, it can operate stably and for long periods without noticeable wear, eliminating the problem of conventional electrodes contaminating the electrolyte with sludge and impurities due to corrosion.

(IV) Environmentally Friendly and Clean

The coating material is chemically stable, and no heavy metal ions are leached during electrolysis, preventing contamination of the cathode product. It is particularly suitable for applications requiring high purity, such as food-grade chemical production and precision electroplating. In wastewater treatment applications, it releases no pollutants and can efficiently catalyze the degradation of organic pollutants, achieving the dual environmental benefits of a “pollution-free treatment process.”

(V) Cost Advantages

The longevity and stability of the MMO titanium anode translate directly into significant maintenance cost advantages: frequent electrode replacement is unnecessary, reducing equipment downtime and replacement labor costs. Dimensional stability eliminates the need for regular inter-electrode spacing adjustment, reducing routine maintenance workload. The base material can be recycled and reused after coating failure, avoiding the wasteful disposal of traditional electrodes.

Calculations show that while the initial purchase cost of the mesh MMO titanium anode is higher than that of traditional electrodes, its lifecycle cost is over 40% lower than that of graphite anodes and approximately 30% lower than that of lead alloy anodes, making it a typical economical product with “high initial investment and low long-term costs.”

Leveraging its strengths in substrate machining, coating technology, precision manufacturing, and customized services, Wstitanium further enhances the application value of mesh MMO titanium anodes, providing you with solutions that balance quality and cost-effectiveness. With the continued development and technological advancements of the electrochemical industry, mesh MMO titanium anodes are poised to achieve breakthroughs in even more emerging fields, particularly in new energy, high-end manufacturing, and environmental protection.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs