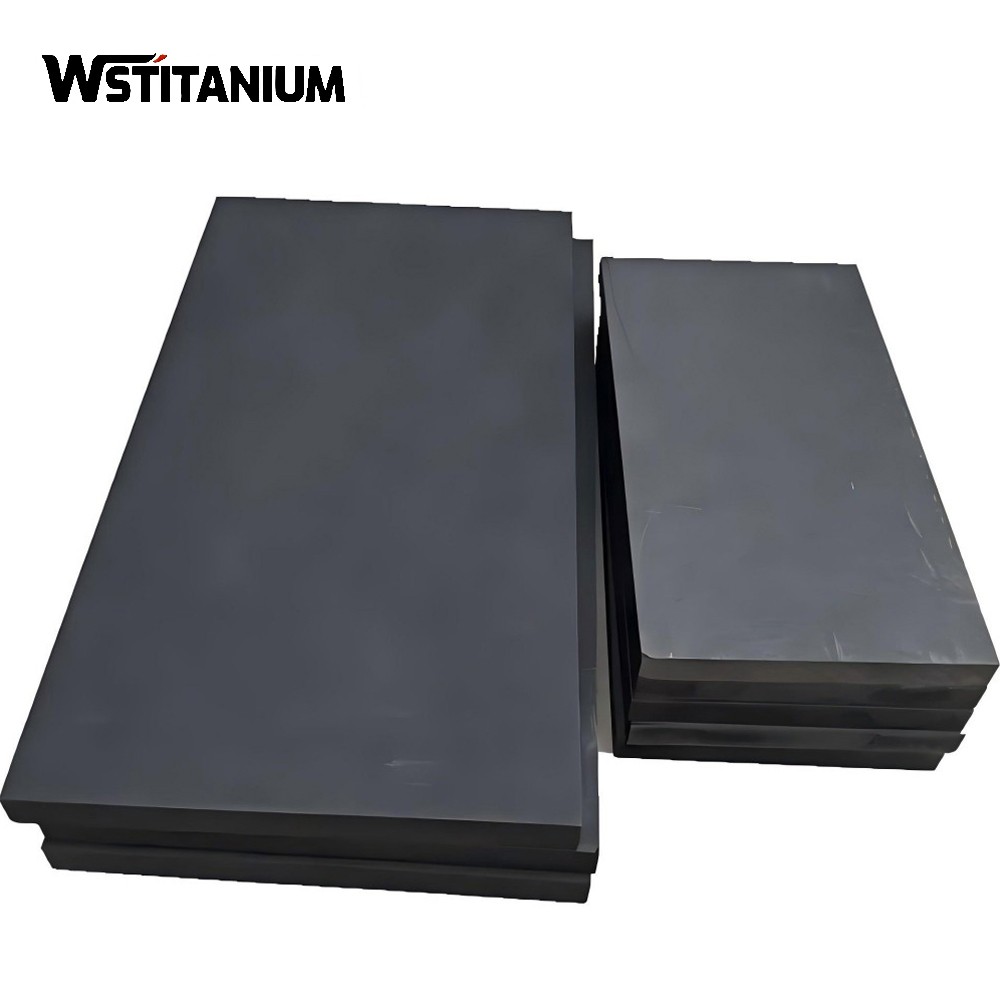

MMO Titanium Anode Plate

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Plate MMO titanium anodes offer the dual advantages of a high-strength substrate and a highly active coating. They significantly reduce the overpotential for oxygen and chlorine evolution, enhance electrocatalytic activity, and resist corrosion from extreme media such as strong acids and bases. Plate MMO titanium anodes have become standard components in fields such as water electrolysis for hydrogen production, electroplating, water treatment, and metal electrolytic refining.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of Plate-Shaped MMO Titanium Anodes

The titanium substrate is the supporting base of the plate-shaped MMO titanium anode. Its material, thickness, and surface treatment directly impact the anode’s mechanical stability and coating adhesion.

Titanium: Industrially pure titanium is used, with TA1 (Gr. 1) and TA2 (Gr. 2) being the most commonly used. TA1 offers higher purity (titanium content ≥ 99.5%) and excellent corrosion resistance, making it suitable for applications such as food-grade water treatment and pharmaceutical intermediate synthesis. TA2 boasts slightly higher strength than TA1, offering a more cost-effective solution and is widely used in industrial applications such as electroplating and conventional electrolysis.

| Element | Grade I | Grade 2 |

| Iron (Fe) | 0.20% max. | 0.30% max. |

| Carbon (C) | 0.08% max. | 0.08% max. |

| Nitrogen (N) | 0.03% max. | 0.03% max. |

| Hydrogen (H) | 0.015% max. | 0.015% max. |

| Oxygen (O) | 0.18% max. | 0.25% max. |

| Single Impurity (Each) | 0.10% max. | 0.10% max. |

| Other Impurities (Total) | 0.40% max. | 0.40% max. |

| Titanium (Ti) | Remainder | Remainder |

Substrate Thickness: The typical range is 1.0mm-5.0mm. Small electrolytic cells (such as laboratory equipment and small electroplating cells) typically use a thickness of 1.0-2.0mm. Large industrial electrolytic cells (such as water electrolysis hydrogen production cells and chlor-alkali industrial cells) typically use a thickness of 3.0-5.0mm to avoid substrate deformation due to the pressure of the electrolyte and long-term workload.

Surface Treatment: To enhance the adhesion between the MMO coating and the titanium substrate, the titanium plate undergoes rigorous surface pretreatment, including sandblasting and pickling. Sandblasting uses aluminum oxide or quartz sand to create a rough “pitted” surface (roughness Ra 1.5-3.0μm), increasing the coating’s adhesion area. Pickling uses oxalic acid or a hydrofluoric acid-nitric acid mixture to remove the surface oxide layer and impurities.

MMO Coating Specifications

The MMO coating is crucial for determining the electrocatalytic performance of the anode. Its composition, thickness, and loading must be customized based on the specific reaction requirements, such as oxygen evolution or chlorine evolution.

Chlorine-evolving coatings, based on RuO₂ (ruthenium dioxide) and combined with TiO₂, SnO₂, and other materials, are suitable for applications such as the chlor-alkali industry and seawater desalination (electrolytic anti-fouling). Oxygen-evolving coatings, based on IrO₂ (iridium dioxide) or IrO₂-RhO₂ (iridium-rhodium oxide), offer enhanced resistance to oxygen corrosion and are suitable for applications such as water electrolysis for hydrogen production, electroplating (such as chrome and nickel plating), and wastewater treatment (anodic oxidation degradation of organic matter). In chlorine-evolving applications, the coating thickness can be controlled at 5-10μm, as Cl⁻ is less corrosive to the coating. In oxygen-evolving applications, the coating thickness needs to be increased to 10-20μm, as the generation of O₂ has a more pronounced scouring effect on the coating.

Dimensions: Standard sizes range from 100mm x 200mm (small) to 1000mm x 2000mm (large). For example, small electroplating cells often use 300mm x 500mm anode plates. Large chlor-alkali electrolysis cells require custom-made, oversized anodes of 800mm x 1500mm.

Flatness and Tolerance: Plate anodes must meet stringent flatness requirements, with a flatness tolerance of ≤1mm per meter. This prevents uneven spacing between the plate and the cathode due to plate bending, which can lead to localized current concentration (“hot spots”) and accelerated coating loss. Dimensional tolerances are within ±0.5mm (thickness) and ±2mm (length and width).

Advantages of Plate-Type MMO Titanium Anodes

Plate-type MMO titanium anodes offer comprehensive advantages across four key dimensions: lifespan, energy consumption, environmental friendliness, and adaptability. Their core competitive advantages can be summarized in the following five key points:

(I) Ultra-Long Service Life

Plate-type MMO titanium anodes offer a service life of 5-10 years. This advantage stems from two key design features: First, the corrosion resistance of the titanium substrate, which resists long-term attack from strong acids (such as H₂SO₄ and HCl), strong bases (such as NaOH), and highly concentrated salt solutions (such as NaCl). Second, the self-protective properties of the MMO coating: the precious metal oxides in the coating form a stable crystal structure, acting solely as catalysts to transfer electrons in electrochemical reactions, resulting in an extremely low self-consumption rate (for example, in oxygen evolution scenarios, the Ir coating can consume as little as 0.1 mg/A/year).

(II) Low Energy Consumption

The high electrocatalytic activity of the MMO coating directly contributes to the economic benefits of low overpotential and high current efficiency. The plate-shaped MMO titanium anode has a chlorine evolution overpotential of only 0.1-0.2V, and an oxygen evolution overpotential of 0.3-0.5V. The current efficiency of the plate-shaped MMO titanium anode can reach 95%-98%. Higher current efficiency means more of the input electrical energy is used for the target reaction (e.g., Cl⁻→Cl₂, H₂O→O₂), and less is wasted on side reactions (e.g., H₂ evolution).

(III) Environmentally Friendly and Pollution-Free

The titanium substrate and MMO coating are extremely chemically stable, resulting in virtually no ion dissolution during operation (precious metal dissolution <0.01 mg/L), and no contamination of the electrolyte or wastewater.

(IV) Strong Structural Adaptability

The plate-shaped structure is the core design highlight of the plate-shaped MMO titanium anode. Compared to tubular anodes (suitable for small spaces and low flow rates) and mesh anodes (suitable for highly dispersed current), the planar structure of plate anodes is more easily compatible with various electrolyzers. They can be installed vertically (e.g., in electroplating cells and water electrolysis hydrogen production cells) or horizontally (e.g., in large-scale sewage treatment electrolyzers). Multiple anode plates can be combined in parallel, allowing the number of plates to be flexibly adjusted based on the electrolyzer capacity, eliminating the need for custom anode designs.

(V) Stable Mechanical Properties

The high strength and toughness of the titanium substrate endow the plate-shaped MMO titanium anode with excellent mechanical properties: its tensile strength reaches 300-500 MPa, allowing it to withstand the electrolyte pressure within the electrolyzer. In high-temperature electrolysis scenarios (e.g., concentrated NaOH solutions at 120°C), the titanium substrate does not suffer from intergranular corrosion. In high-flow electrolytes (e.g., desalination electrolysis anti-fouling systems with flow rates >2 m/s), the MMO coating does not flake off due to liquid erosion.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws