MMO Titanium Anode Rod

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

The rod MMO titanium anode (titanium mixed metal oxide rod anode), a key branch of the dimensionally stable anode (DSA), has become a key component for solving electrochemical reaction and cathodic protection challenges under complex operating conditions thanks to its unique design and superior performance. This anode utilizes an industrially pure titanium rod as its substrate. Through precise thermal decomposition, a catalytic coating composed of precious metal oxides such as ruthenium, iridium, and tantalum is applied to the surface, creating a core functional element that combines high-strength structural support with efficient electrochemical activity.

Compared to other MMO titanium anode forms such as mesh and ribbon, the rod structure offers irreplaceable advantages in spatial adaptability, single-point current output stability, and installation flexibility. Its rod form enables precise electrochemical control in confined spaces, complex vessels, and specific locations.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of Rod-Shaped MMO Titanium Anodes

The specification system for rod MMO titanium anodes is structured around four core dimensions: substrate, coating, structural dimensions, and electrochemical performance. A combination of different specifications precisely matches diverse operating requirements.

(I) Substrate

The substrate serves as the structural support for rod-shaped anodes and directly determines their mechanical strength and corrosion resistance. Currently, pure titanium (Gr1 or Gr2) conforming to ASTM B348 Grade 1 is the mainstream material. The physical parameters of titanium rods can be customized based on the application scenario. Diameters range from 3.2mm to 25mm, with standard diameters of 6.4mm, 9.5mm, and 12.7mm. Lengths of 2mm (micro) or 30mm (heavy) are available for special applications. Standard lengths are 500mm, 1000mm, and 1500mm, with lengths up to 3000mm customizable. The substrate’s mechanical properties must meet the following requirements: tensile strength ≥ 240MPa, yield strength ≥ 170MPa, and elongation ≥ 20%.

| Element | Grade I | Grade 2 |

| Iron (Fe) | 0.20% max. | 0.30% max. |

| Carbon (C) | 0.08% max. | 0.08% max. |

| Nitrogen (N) | 0.03% max. | 0.03% max. |

| Hydrogen (H) | 0.015% max. | 0.015% max. |

| Oxygen (O) | 0.18% max. | 0.25% max. |

| Single Impurity (Each) | 0.10% max. | 0.10% max. |

| Other Impurities (Total) | 0.40% max. | 0.40% max. |

| Titanium (Ti) | Remainder | Remainder |

(II) Coating

The coating is the core of the rod MMO titanium anode’s catalytic function and determines the electrode’s electrochemical performance. A RuO₂-IrO₂ composite system is used for chlorine evolution. An IrO₂-Ta₂O₅ mixed system is used for oxygen evolution. The coating thickness must reach 5.0-20.0 microns to ensure a complete catalytic and protective layer. A multi-layer coating-thermal decomposition technique is used. Each layer is controlled to a thickness of 0.3-0.5 microns, and a dense crystalline layer is formed through high-temperature sintering at 400-600°C. The wear rate of the coating and substrate must be as low as 0.5-1.0 μg/A·h.

(III) Electrochemical Performance

Electrochemical performance is a key indicator of the practicality of rod anodes, primarily including current characteristics, potential characteristics, and lifespan. The chlorine evolution overpotential for chlorine evolution systems is ≤1.38V (vs. SHE). The overpotential of the oxygen evolution system is 25%-35% lower than that of traditional lead anodes, effectively reducing cell voltage and energy consumption. In conventional environments such as soil and freshwater, the design lifespan is 20-30 years; in harsh environments such as industrial electrolysis, the service life can still reach 5-8 years.

(IV) Environmental Adaptability

The rod MMO titanium anode has strong environmental adaptability. Its acid and alkaline resistance covers the full pH range of 0-14, allowing it to operate stably in extreme acid and alkaline environments such as concentrated sulfuric acid and caustic soda. Its salt resistance has been tested to withstand Cl⁻ concentrations exceeding 300g/L, making it suitable for seawater and high-salt wastewater environments. It has a short-term temperature resistance of up to 80°C and, after coating enhancement, can withstand temperatures exceeding 100°C.

Advantages of Rod-Shaped MMO Titanium Anodes

Rod MMO titanium anodes offer unique advantages in structural characteristics, performance, and application flexibility, specifically reflected in the following five dimensions:

(I) Spatial Adaptability

The rod structure’s greatest advantage lies in its exceptional spatial adaptability, allowing it to penetrate deep into confined spaces such as container interiors, pipe crevices, and equipment cavities. This solves the localized electrochemical challenges that mesh or ribbon anodes struggle to cover. In enclosed equipment such as water heater tanks and heat exchangers, single or multiple rod-shaped anodes can be precisely positioned in high-corrosion areas for targeted protection.

(II) Dimensional Stability

The titanium substrate achieves zero electrochemical loss, and combined with the extremely low-wear MMO coating, the rod-shaped anode maintains virtually unchanged geometric dimensions throughout its design life. Cell voltage fluctuations are controlled within ±2%. In soil cathodic protection applications, its lifespan can reach 20-30 years, far exceeding the 5-8 years of high-silicon cast iron anodes.

(3) High Current Density

The high catalytic activity of the MMO coating gives the rod anode excellent current carrying capacity. Given the same cross-sectional area, its permissible current density is 3-5 times that of a graphite anode. Because the coating reduces the reaction overpotential, its operating voltage is 10%-20% lower than that of traditional graphite anodes. When used in small sodium hypochlorite generators, power consumption can be reduced by 150-200 kWh per ton of available chlorine.

(4) Superior Corrosion Resistance

The titanium substrate and the precious metal oxide coating form a synergistic protective system, giving the rod anode excellent corrosion resistance. It can operate stably in a variety of harsh media, including acidic and alkaline environments with a pH range of 0-14, high-salt wastewater, and seawater, without significant corrosion damage. The coating material is chemically stable, and no heavy metal ions are leached during electrolysis, making it particularly suitable for food-grade electrolysis and precision electroplating.

(5) Cost Advantage

The rod structure is extremely easy to install and can be quickly assembled using various methods, including threaded connections, clamps, and welding. While the initial purchase cost is higher than traditional anodes, the overall lifecycle cost advantage is significant. Its longevity reduces replacement frequency and labor costs. Its dimensional stability eliminates the need for frequent equipment adjustments and maintenance.

Wstitanium independently develops 12 specialized coating formulations, resulting in a coating degradation rate of less than 0.3μm per year. For specialized applications, Wstitanium can customize rod-shaped anodes with diameters ranging from 2 to 30mm and lengths from 100 to 3000mm.Rod-shaped MMO titanium anodes are precision solutions for electrochemistry and corrosion protection. They play an irreplaceable role in applications ranging from residential water heaters to industrial storage tanks, from laboratory equipment to marine engineering.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

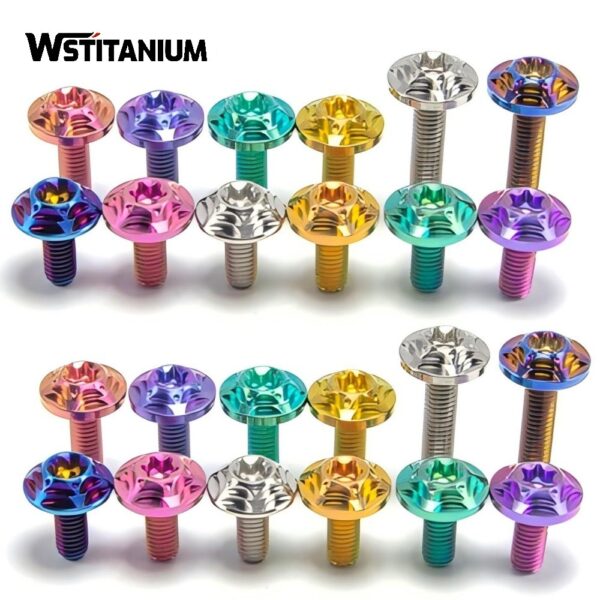

Anodized Titanium Screws

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Burnt Titanium Wheel Bolt