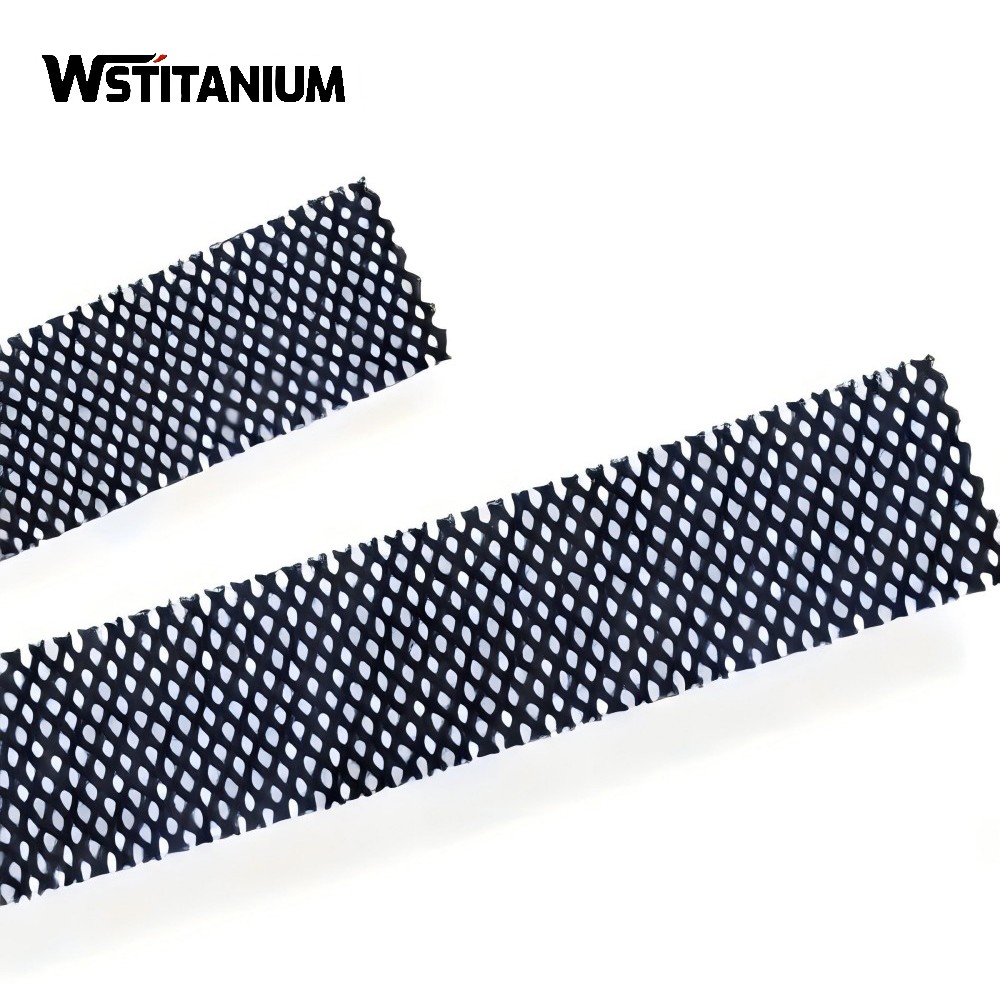

MMO Titanium Anode Strip

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a key member of the MMO family, the Strip MMO titanium anode, with its unique design and exceptional performance, has become a preferred solution in numerous high-end industrial fields.

Its narrow, flexible structure perfectly suits the requirements of complex curved surface protection and installation in dense spaces, achieving groundbreaking applications in cathodic protection, wastewater treatment, and precision electrolysis. Compared to plate and tubular anodes, the Strip MMO titanium anode exhibits significant advantages in current distribution uniformity and catalytic efficiency per unit area, promoting the in-depth application of electrochemical technology in a wider range of niche applications.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of MMO Titanium Strip Anodes

The specification system for MMO titanium strip anodes is structured around three core dimensions: substrate, coating, and size, allowing for precise customization based on specific operating requirements.

(I) Substrate

The substrate, as the structural foundation of the anode, directly impacts the product’s mechanical strength and corrosion life. The industry generally uses TA1 or TA2 (or equivalent international standards Gr1 and Gr2) industrially pure titanium as the substrate material. Titanium forms a dense oxide film in highly corrosive environments, such as acidic and high-salt environments, effectively resisting corrosion. The mechanical properties of the substrate must meet tensile strength ≥240 MPa and elongation ≥20% to ensure resistance to breakage during bending, installation, and long-term operation. To enhance coating adhesion, the titanium strip surface undergoes pre-treatments such as sandblasting, pickling, and etching to create a porous structure with a roughness of Ra 1.5-3.0 μm, preventing coating flaking during service.

(II) Coating

The coating is a key factor in determining the electrochemical performance of the anode. Its composition, ratio, and parameters must be precisely tailored to the application scenario. Mainstream coating systems fall into two main categories: IrO₂/RuO₂/platinum/TiO₂ composite coatings are suitable for applications where chlorine evolution is the primary reaction, such as seawater chlorination systems; IrO₂/Ta₂O₅ coatings focus on oxygen evolution and are suitable for multi-media cathodic protection environments such as soil and freshwater. Coating thickness is typically controlled between 20-50μm, with a coating weight of 10-20g/m² and a distribution uniformity tolerance of no more than ±5%.

(III) Physical Dimensions

The physical dimensions of MMO titanium anode strips are highly customizable, with standard widths ranging from 6.35-25mm and thicknesses from 0.635-1.2mm. Single roll lengths can be customized from 152-1000m, meeting the continuous installation requirements of large-scale projects. In specialized applications, the strips can be cut to achieve segmented use with a minimum unit length of ≤1m.

Advantages of Strip MMO Titanium Anodes

Strip MMO titanium anodes offer comprehensive advantages in electrochemical performance, structural adaptability, and cost-effectiveness.

(I) Excellent Electrochemical Performance

The core advantage of Strip MMO titanium anodes lies in their exceptional electrocatalytic activity and stability. The precious metal oxide coating significantly reduces the overpotential of oxygen and chlorine evolution reactions. In chlor-alkali production, the cell voltage can be reduced by 140-700mV and DC power consumption by 10%-20% compared to graphite anodes. Their current distribution is particularly uniform, ensuring a potential difference of less than ±0.05V across the protected metal surface, completely eliminating the blind spot protection issue associated with traditional point anodes. In terms of current carrying capacity, these anodes can withstand high current densities exceeding 600A/m², far exceeding the 8A/dm² limit of graphite anodes.

(II) Superior Corrosion Resistance

The combination of the titanium substrate and precious metal coating imparts exceptional corrosion resistance to the anode, ensuring stability in harsh environments such as low pH and high chloride ion concentrations. In cathodic protection applications, the coating loss rate can be as low as 2 mg/A·a, and the service life generally exceeds 20 years.

(III) Flexible Adaptability

Strip’s core feature distinguishes it from other anodes, giving it exceptional installation adaptability. The anode can be bent to a curvature of ≤1m in diameter, allowing it to fit snugly onto irregular surfaces such as tank floors and curved pipes, eliminating blind spots that traditional rigid anodes struggle to reach. In confined spaces such as densely packed pipelines, its narrow shape effectively mitigates shielding effects, increasing the protection potential compliance rate from 65% to 95%.

(IV) Significant Economic Benefits

Although the initial investment in Strip MMO titanium anodes is higher than that of traditional electrodes, they offer significant lifecycle cost advantages. For example, in tank cathodic protection, their long life and low maintenance can reduce lifecycle costs by over 50%. In terms of energy consumption, the combination of low overpotential characteristics and high current efficiency significantly reduces the power consumption per unit product. In the chlor-alkali industry alone, the use of MMO titanium anodes can save approximately 300 million kWh of electricity worldwide each year.

Applications of Strip MMO Titanium Anodes

Leveraging their multi-dimensional performance advantages, strip MMO titanium anodes have achieved large-scale application in a variety of fields, including cathodic protection, environmental protection, and precision manufacturing.

(I) Cathodic Protection

Cathode protection is a core application scenario for strip MMO titanium anodes, particularly suitable for long-term corrosion protection of metal structures. In storage tank projects, these anodes can replace traditional high-silicon cast iron anodes, maintaining a stable tank bottom potential of -0.85V to -0.90V (CSE), reducing the corrosion rate by 90%, and effectively addressing electrochemical corrosion issues on tank floors.

In marine engineering, their high-pressure and seawater corrosion resistance are fully utilized, allowing them to withstand deep-sea environments up to 10MPa. The anode polarization voltage is controlled within 200mV, a 60% reduction compared to traditional graphite anodes. They are widely used for corrosion protection of ship ballast tanks and offshore platform pile foundations. In underground pipeline protection, they provide uniform protection over long distances, effectively combating soil corrosion and stray current interference.

(2) Environmental Protection

In the environmental protection field, the electrocatalytic activity of the Strip MMO titanium anode provides a highly effective solution for wastewater treatment. In the treatment of high-salinity wastewater, it can synergistically achieve electrocatalytic oxidation degradation and desalination. For difficult-to-treat water bodies such as coal chemical phenol wastewater and electroplating heavy metal wastewater, COD removal rates exceeding 85% and heavy metal recovery rates exceeding 95% are achieved. In drinking water purification, this anode effectively kills bacteria and viruses through electrochemical oxidation, replacing traditional chlorine disinfection processes and fundamentally eliminating the formation of harmful byproducts such as chloroform.

(3) Precision Electrolysis

In the field of precision manufacturing, the current uniformity and dimensional stability of the Strip MMO titanium anode play a critical role. In precision electroplating, as an alternative to soluble anodes, it can improve the thickness uniformity of gold plating on 5G communication devices to ±3%, reducing scrap rates by 80%.

In aluminum foil electrolysis, iridium-tantalum-coated strip anodes have a service life of 9-18 months in electrolyte systems such as ammonium adipate. Their oxygen evolution potential remains consistently below 1.40V, providing reliable support for the production of medium- and high-voltage electrolytic foil. In metal electrolytic extraction, IrO₂-SnO₂ composite-coated strip anodes can effectively improve the electrolysis efficiency and product purity of metals such as copper and zinc.

Related products

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs