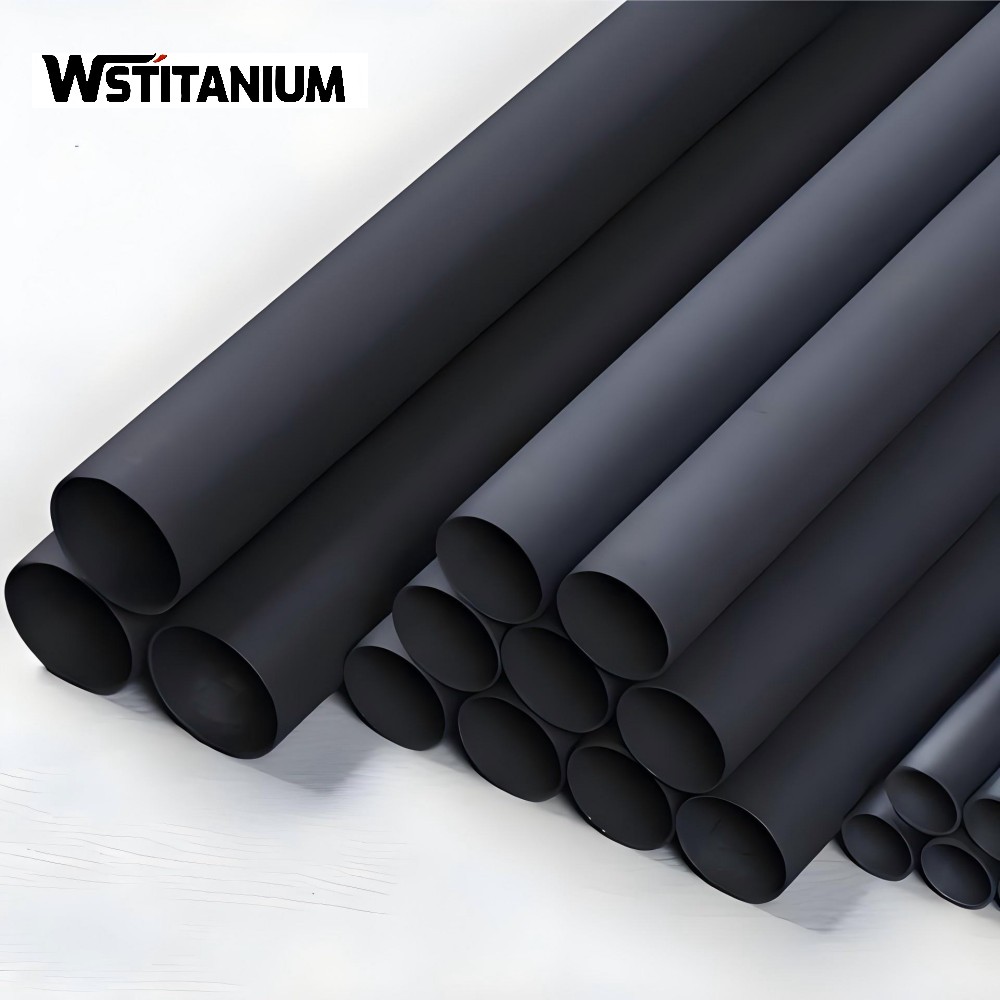

MMO Titanium Anode Tubular

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a key member of the titanium-based metal oxide-coated electrode (MMO) family, tubular MMO titanium anodes, with their unique hollow cylindrical structure and excellent overall performance, have become a preferred electrode solution in numerous industrial applications. Mixed metal oxide tubular titanium anodes, also known as dimensionally stable anodes (DSA), utilize a composite coating of precious metal oxides, such as ruthenium, iridium, and tantalum, applied to the surface of an industrially pure titanium tube. This coating combines the corrosion resistance of titanium with the high electrochemical activity of the coating.

The hollow structure of tubular MMO titanium anodes perfectly addresses key challenges such as electrolyte circulation, gas escape, and efficient space utilization, enabling their application in water treatment, electrolytic manufacturing, and cathodic protection.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Specifications of Tubular MMO Titanium Anodes

Specifications for tubular MMO titanium anodes focus on three core dimensions: substrate properties, coating, and structural dimensions. Wstitanium can be precisely customized to meet application requirements, with key parameters directly determining their applicable scenarios and performance limits.

(I) Substrate

The substrate serves as the structural foundation of the anode, and its performance directly impacts its mechanical strength and service life. The substrate material is industrially graded TA1 and TA2 (corresponding to international standards Gr1 and Gr2), with a purity of ≥99.5%. This substrate forms a dense oxide film in highly corrosive environments such as strong acids, high salt concentrations, and seawater, effectively resisting corrosion. The substrate’s mechanical properties must meet requirements such as a tensile strength of ≥240 MPa and an elongation of ≥20%, ensuring resistance to deformation and fracture under complex conditions such as high pressure and deep burial.

To enhance coating adhesion, the titanium tube surface undergoes pre-treatment by sandblasting, electrolytic polishing, or chemical etching to create a rough surface with an Ra of 1.6-6.3 μm, ensuring a secure bond between the coating and the substrate. In terms of physical dimensions, titanium tubes typically have an outer diameter of 10mm to 50mm, with a wall thickness of 0.5mm to 3mm (thin-wall tubes are suitable for low-pressure applications, while thick-wall tubes are suitable for high-pressure electrolysis systems). Single tube lengths range from 0.5m to 6m, and can be extended via flanges or argon arc welding to meet the installation requirements of different equipment.

(II) Coatings

The coating is crucial for determining the electrochemical performance of the anode. Its composition ratio and parameters must be precisely controlled based on the reaction type. Mainstream coating systems fall into two categories: ruthenium-iridium-titanium composite coatings (RuO₂/IrO₂/platinum) are suitable for chlorine evolution-dominated applications, such as the chlor-alkali industry and seawater chlorination; iridium-tantalum-titanium coatings (IrO₂/Ta₂O₅/TiO₂) focus on oxygen evolution reactions and are suitable for applications such as cathodic protection and water electrolysis. The coating thickness should be controlled between 5μm and 20μm. Excessively thick coatings are prone to cracking, while excessively thin coatings may result in insufficient abrasion resistance. The coating weight should reach 8-15g/m², with a uniformity tolerance of no more than ±5%.

High-quality coatings should have an adhesion strength of ≥30MPa (verified by thermal shock or tensile testing) and a resistivity of ≤10⁻⁴Ω·cm, ensuring low-energy conduction. Regarding electrochemical performance, the coating overpotential should be ≤0.3V at rated current density, an oxygen evolution potential of <1.45V in a 1mol/L H₂SO₄ solution, a polarization ratio of ≤50mV/dec, and an annual coating loss rate of ≤10%, ensuring long-term stable operation.

(III) Structure

The structural design and operating parameters of tubular anodes must be tailored to the specific application scenario. For interface design, flange seals or threaded connections are typically used. For high-voltage applications, IP68-rated sealing structures are required to prevent electrolyte leakage. The inner wall retains a smooth surface to promote fluid flow, while the outer wall is coated to achieve reaction functionality, or both the inner and outer walls are coated to increase the reaction area.

The applicable pH range is 1-14, and it is compatible with acidic, neutral, and alkaline electrolytes. The operating temperature range is -10°C to 80°C. A cooling system is required in high-temperature environments to prevent coating degradation. The operating pressure is 0.1MPa to 1.0MPa, depending on the wall thickness and connection method. Regarding electrochemical operating parameters, the typical operating current density is 100A/m² to 1000A/m² (up to 2000A/m² for desalination and as low as 50A/m² for cathodic protection). The limiting current density is ≥1500A/m²; exceeding this value can easily lead to coating burnout.

Advantages of Tubular MMO Titanium Anodes

Compared to traditional graphite, lead, and other MMO anodes, tubular MMO titanium anodes offer multiple advantages in electrochemical performance, structural compatibility, and economic efficiency, specifically in the following dimensions:

(I) Highly Efficient and Stable Electrochemical Performance

The core advantages of tubular MMO titanium anodes lie in their high catalytic activity and low energy consumption. The precious metal oxide coating significantly reduces the reaction overpotential, enabling current efficiencies exceeding 95% in the chlor-alkali industry and reducing energy consumption by 10%-30% compared to graphite anodes.

The hollow structure promotes uniform electrolyte flow, avoiding localized concentration polarization. It also facilitates the rapid escape of reactive gases (such as oxygen and chlorine), reducing voltage fluctuations caused by bubble accumulation. The cell voltage remains stable at 1.5V-3.5V, significantly improving operational stability. Dimensional stability is a particularly significant advantage, with anode dimensional change of less than 0.1% during electrolysis. This prevents changes in the electrolysis spacing due to electrode deformation and ensures stable long-term operating parameters.

(2) Superior Corrosion Resistance

The combination of a titanium substrate and a precious metal coating imparts exceptional corrosion resistance to the anode, ensuring stable performance in harsh environments such as seawater, strong acids, and strong alkalis. The coating loss rate is typically less than 10 mg/(A·h), resulting in a typical lifespan of 5-15 years and a lifespan of 3-5 years in deep-sea or highly acidic environments. In purity-sensitive applications such as electroplating and drinking water treatment, this anode can completely eliminate heavy metal or particulate contamination, improving product quality and processing safety.

(3) Structural Adaptability

The tubular structure is a core feature that distinguishes this anode from other anodes, providing exceptional adaptability. Its hollow form perfectly complements cylindrical reactors and fluid handling systems, ensuring efficient electrolyte flow and uniform reaction. In applications such as water electrolysis and wastewater treatment, the reaction efficiency is over 30% higher than that of plate-type anodes. For applications such as deep well cathodic protection and underground pipeline corrosion prevention, tubular anodes can be buried vertically in soil or water, significantly saving surface space and providing extended protection coverage.

(IV) Economic and Environmental Benefits

Although the initial purchase cost of tubular MMO titanium anodes is higher than that of traditional electrodes, they offer significant lifecycle cost advantages. In the chlor-alkali industry, for example, their long lifespan and low energy consumption can reduce overall costs by over 40%. In cathodic protection systems, a single tubular anode provides a larger coverage area, reducing the number of anodes and the frequency of replacement, resulting in outstanding long-term economic benefits.

The coating is highly stable, releasing virtually no heavy metals or particulate pollutants, and thus avoiding the secondary contamination associated with lead anodes. In water treatment applications, it can reduce the formation of disinfection byproducts, meeting green industry standards.

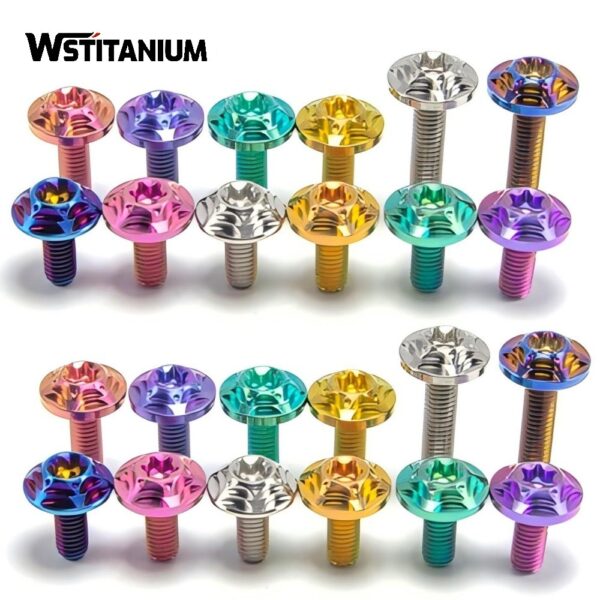

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts