Titanium Anode For Electrodialysis

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Electrodialysis, with its core advantages of low energy consumption, high selectivity, and modularity, has become a key technology for seawater desalination, brackish water desalination, and industrial wastewater recycling. However, the long-term stability of electrodialysis systems is often limited by the performance of their core components: the electrodes. Traditional electrodes, such as graphite and lead-based alloys, are prone to corrosion, dissolution, and severe polarization in the high-salt, strong acid-base electrodialysis environment, significantly hindering the industrial application of electrodialysis technology.

The emergence of the MMO titanium anode (mixed metal oxide-coated titanium anode) provides a key to breaking through the bottleneck of electrodialysis technology. This electrode material, composed of an industrially pure titanium matrix and an active coating of multiple metal oxides (such as ruthenium-iridium, iridium-tantalum, and ruthenium-iridium-tantalum), achieves a triple breakthrough in corrosion resistance, catalytic activity, and stability through precise composition design and advanced fabrication processes. In electrodialysis systems, MMO titanium anodes not only reduce the overpotential for chlorine/oxygen evolution by 0.2-0.5V, reducing system energy consumption by 15%-25%, but also operate stably for over 8,000 hours in extreme environments with salinity levels of 5%-20%, with a lifespan 4-6 times that of traditional lead anodes. Currently, over 85% of high-end electrodialysis equipment worldwide uses MMO titanium anodes, and their penetration in seawater desalination, electronic ultrapure water production, and lithium extraction from salt lakes is growing at an annual rate of 12%.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Applications of Electrodialysis

Electrodialysis technology, based on the principle of “ion selective migration,” uses an electric field to drive ions in water through ion exchange membranes, achieving water purification and resource recovery.

Water purification: In seawater desalination, electrodialysis can reduce the salinity of seawater from 35,000 mg/L to below 500 mg/L, meeting drinking water standards, while consuming only 60%-70% of the energy required by reverse osmosis technology. It is particularly suitable for islands and coastal areas with water shortages. In brackish water desalination, electrodialysis can effectively remove high fluoride, arsenic, and salt levels in groundwater. For example, data from a brackish water project shows that the fluoride content in treated water has been reduced from 2.8 mg/L to below 0.5 mg/L, meeting drinking water standards.

Industrial wastewater recovery: In electroplating wastewater treatment, electrodialysis can recover heavy metal ions such as nickel, copper, and chromium, with a recovery rate exceeding 95%. After adopting this technology, electroplating plants have reduced heavy metal emissions by 12 tons annually and saved over 3 million yuan in raw material costs. In dyeing wastewater treatment, electrodialysis removes salts and organic pigments from wastewater, increasing wastewater reuse to 70% and reducing fresh water consumption.

High-end manufacturing: In the production of ultrapure water for electronics, electrodialysis, as a “deep desalination” step, can increase water resistivity to 18.2 MΩ·cm, meeting the stringent ultrapure water requirements of chip manufacturing. In lithium extraction from salt lakes, electrodialysis replaces traditional evaporation, achieving efficient separation of lithium from sodium and potassium ions. This increases lithium recovery from 70% to over 90%, reduces energy consumption by 40%, and prevents ecological damage to salt lakes.

Working Principle of the MMO Titanium Anode

The MMO titanium anode plays a key role in the electrodialysis system by providing the electric field driving force and catalyzing the electrode reaction. In the electrodialysis system, the MMO titanium anode acts as the anode, primarily undergoing the chlorine evolution reaction (a Cl⁻-dominated system) or the oxygen evolution reaction (an OH⁻-dominated system).

Electric Field Drive: When the electrodialysis system is energized, a positive potential is generated on the surface of the MMO titanium anode, creating an electric field gradient. Under the influence of the electric field, anions (such as Cl⁻, SO₄²⁻, and OH⁻) in the water migrate toward the anode, while cations (such as Na⁺, Ca²⁺, and Mg²⁺) migrate toward the cathode, achieving initial ion separation.

Anode Catalysis: Depending on the water composition, two core reactions occur at the anode:

Chlorine evolution reaction (high-salt systems, such as seawater and electroplating wastewater): The ruthenium-iridium oxide (RuO₂-IrO₂) on the surface of the MMO titanium anode acts as a catalytic active site, lowering the activation energy for Cl⁻ oxidation. The reaction equation is 2Cl⁻ – 2e⁻ → Cl₂↑. The overpotential of this reaction is only 0.1-0.2V, far lower than the 0.5-0.7V of traditional graphite electrodes, significantly reducing energy consumption.

Oxygen evolution reaction (low-salt or alkaline systems, such as ultrapure water preparation and printing and dyeing wastewater): When the Cl⁻ concentration in the water is low, OH⁻ is preferentially oxidized at the anode. The iridium tantalum oxide (IrO₂-Ta₂O₅) coating in the MMO titanium anode catalyzes this reaction, with the equation: 4OH⁻ – 4e⁻ → 2H₂O + O₂↑. The overpotential is controlled between 0.25-0.35V to avoid side reactions with organic pollutants induced by high potentials.

Electron conduction and reaction balance: The titanium substrate of the MMO titanium anode has excellent conductivity, efficiently transferring electrons from the external circuit to the active sites of the coating. Furthermore, the coating’s porous structure (pore size 50-200nm) provides escape channels for reaction products (Cl₂, O₂), preventing “electrode polarization” caused by bubble adhesion and maintaining a stable reaction.

Anti-organic pollution: The high potential of the MMO coating (1.2-1.5V vs SHE) can quickly oxidize organic pollutants adsorbed on the surface, decomposing them into CO₂ and H₂O, preventing clogging of active sites. At the same time, the coating’s nanoporous structure (specific surface area > 10m²/g) can disperse the adsorption density of organic pollutants and maintain stable catalytic activity. In the treatment of printing and dyeing wastewater, the activity decay rate of the MMO titanium anode is only 5%/year, while that of the graphite electrode is 30%/year.

MMO Titanium Anode Types

Based on the water quality characteristics (salinity, pH, contaminant types) and requirements (current density, energy consumption targets) of the electrodialysis system, MMO titanium anodes can be divided into four categories. Each product has significant differences in coating composition and performance emphasis to suit different application scenarios.

1. Ruthenium-IrO₂ Titanium Anode (RuO₂-IrO₂/Ti)

This utilizes a ruthenium-iridium oxide active coating (Ru:Ir molar ratio 3:1-5:1). It features “high chlorine evolution activity + low energy consumption,” with a chlorine evolution overpotential as low as 0.1V and current efficiency exceeding 95%. It is suitable for high-salinity systems with Cl⁻ concentrations > 5000mg/L. Typical applications include seawater desalination, electroplating wastewater recovery (containing high chloride content), and electrodialysis desalination in the chlor-alkali industry.

2. Iridium-Tantalum-Titanium Anode (IrO₂-Ta₂O₅/Ti)

This anode features an iridium-tantalum oxide active coating (iridium-tantalum molar ratio of 1:1-2:1), focusing on “high oxidation resistance and alkaline corrosion resistance.” Its oxygen evolution overpotential is as low as 0.25V and it is stable across the full pH range of 0-14, making it suitable for low-salt or alkaline electrodialysis systems. Typical applications include electronic ultrapure water production (deep desalination, Cl⁻ concentration < 10mg/L), alkaline wastewater treatment (such as papermaking wastewater), and electrodialysis purification for hydrogen production using water electrolysis.

3. Ruthenium-Iridium-Tantalum-Titanium Anode (RuO₂-IrO₂-Ta₂O₅/Ti)

This ternary composite coating (Ruthenium:Iridium:Tantalum = 4:3:3) combines the triple advantages of “chlorine evolution activity, corrosion resistance, and anti-scaling.” Its balanced overpotentials for chlorine and oxygen evolution are 0.15V and 0.3V, respectively, making it suitable for complex mixed salt systems. Typical applications include brackish water desalination (high calcium and magnesium content, low chloride content), lithium extraction from salt lakes (separation of Li⁺ from Na⁺ and K⁺), and desalination of industrial circulating water. A salt lake lithium extraction project using this anode has increased the electrodialysis lithium recovery rate from 85% to 92%.

4. Specially Structured MMO Titanium Anode

Mesh MMO Titanium Anode: Utilizing a titanium mesh (pore size 2-5mm) as a substrate and a coating thickness of 0.5-2μm, it offers the advantages of “high specific surface area + low flow resistance” and is suitable for compact electrodialysis membrane stack designs, reducing system volume by 30%. It is commonly used in small household water purifiers and mobile desalination equipment.

Tubular MMO Titanium Anode: Utilizing a titanium tube substrate (diameter 10-50mm), the coating uniformly covers the inner and outer surfaces. Suitable for use in tubular electrodialysis reactors, it enhances water agitation and reduces concentration polarization. It excels in treating high-viscosity wastewater (such as food processing wastewater), improving COD removal by 15%.

Flexible MMO titanium anode: Based on titanium foil (thickness 0.1-0.3mm), the coating is modified with a flexible adhesive and can be bent to fit irregular electrodialysis devices. It is suitable for special-shaped membrane stacks or portable treatment equipment, such as small electrodialysis water purification devices for emergency disaster relief.

Related products

-

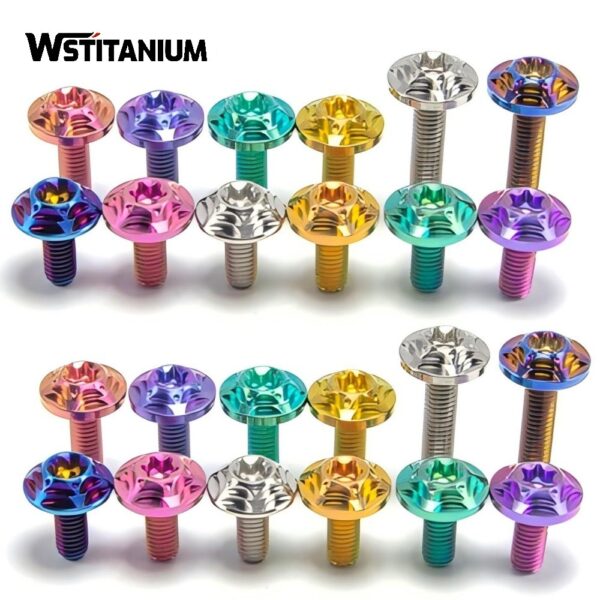

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts

-

Titanium Fasteners

Burnt Titanium Wheel Bolt