Titanium Anode For Seawater Desalination

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

The global freshwater crisis is becoming one of the core challenges constraining human development. 97.5% of Earth’s surface water is seawater. Efficient and cost-effective desalination has become a hot topic in global research and industry. With technological advancements, desalination has moved from laboratory exploration to large-scale application, and breakthroughs in core materials are a key driver of this progress.

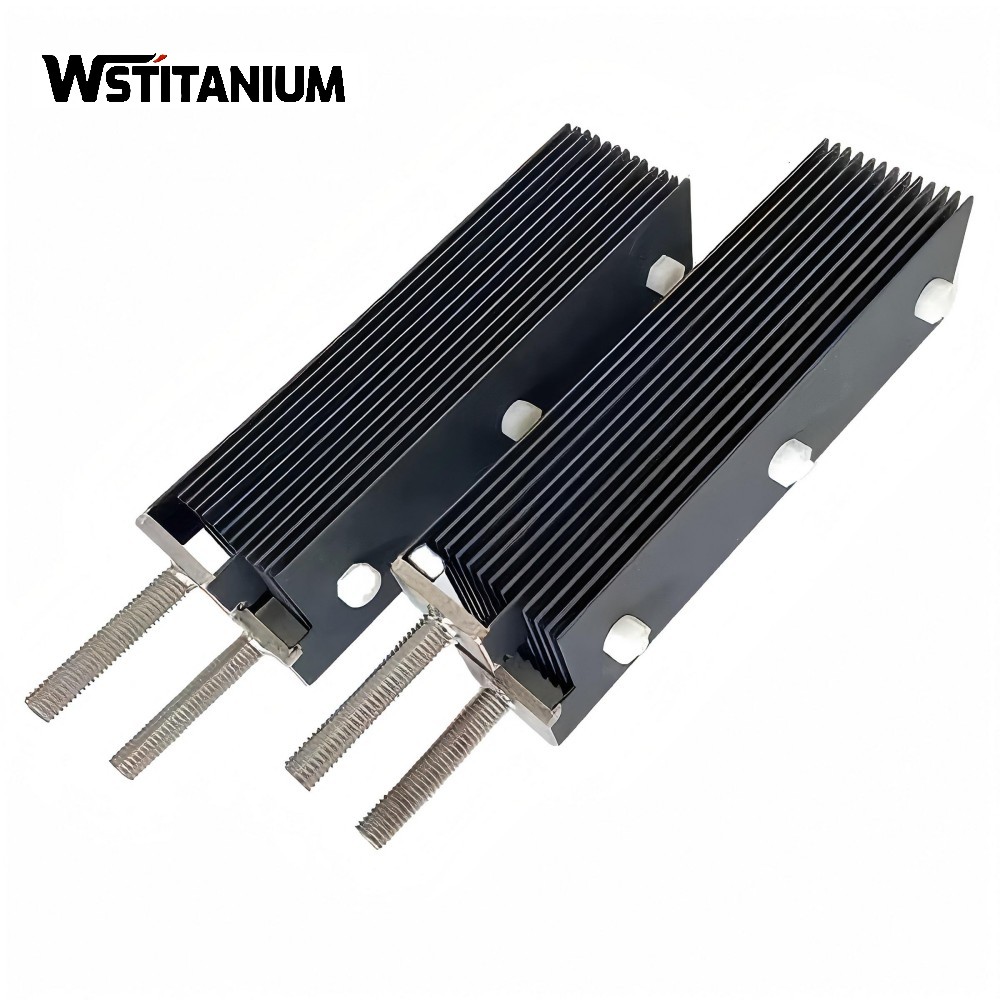

Mixed metal oxide titanium anodes (MMO titanium anodes), a novel functional electrode material, utilize a base of industrially pure titanium coated with precious metal oxides such as ruthenium and iridium. Their exceptional corrosion resistance, high catalytic activity, and long-term stability have achieved groundbreaking applications in desalination. MMO titanium anodes address the challenges of rapid corrosion loss, low electrolysis efficiency, and high maintenance costs in high-salinity environments, making them an indispensable core component in modern desalination systems.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The mechanism of action of MMO titanium anodes in seawater desalination systems revolves around electrochemistry. Its core principle is the synergistic effect of the coating’s catalytic activity and the stability of the titanium substrate, achieving multiple functions such as desalination, scale removal, and disinfection. MMO titanium anodes utilize a “substrate-coating” composite structure. The titanium substrate is Gr1/Gr2 grade industrial pure titanium, typically 0.5-3mm thick. Sandblasting creates a roughened surface to enhance coating adhesion. The surface coating consists of a specific mixture of active precious metal oxides (such as RuO₂ and IrO₂) and auxiliary oxides (such as TiO₂ and Ta₂O₅). Produced through multiple coatings using a sol-gel process and high-temperature sintering, the titanium substrate, while only 20-50μm thick, forms a honeycomb-like porous structure with a porosity of 35-45%, increasing the effective reaction area by 5-8 times. This structure leverages the corrosion resistance of the titanium substrate and the efficient electrocatalysis achieved through the precious metal coating, forming a dual “physical + chemical” protection system.

(I) Electrochemical Desalination

In the electrochemical treatment unit for seawater desalination, the MMO titanium anode acts as the anode to undergo an oxidation reaction.

Chlorine Evolution and Disinfection: Chloride ions in seawater are catalytically oxidized on the anode surface to produce chlorine gas (Cl₂). This chlorine gas further reacts with water to produce hypochlorous acid (HClO), which exerts a strong oxidative disinfectant effect, effectively killing bacteria, algae, and other microorganisms in seawater, with an algae removal rate of up to 98%. The ruthenium-based coating significantly reduces the chlorine evolution overpotential, increasing chlorine evolution efficiency by over 30%.

Pollutant Degradation: Hydroxyl radicals (・OH) and ozone (O₃) are also produced on the anode surface during electrolysis. These substances not only enhance the disinfection effect but also oxidize and decompose organic pollutants in seawater, reducing the treatment load of subsequent desalination units.

Electrochemical descaling: High concentrations of hydroxide ions formed near the cathode alter the chemical balance of seawater, prompting the precipitation of calcium and magnesium ions. The active substances produced by the MMO anode disrupt the scale lattice structure, promoting its physical exfoliation, thereby reducing scaling and clogging of desalination membranes and heat exchangers at the source.

The low polarization of the MMO titanium anode is key to improving desalination efficiency. Its polarization voltage can be controlled to less than 200mV, over 60% lower than that of traditional graphite anodes. The high catalytic activity of the precious metal coating reduces the oxygen evolution overpotential from 1.6V to 1.3V. This efficient energy conversion capability directly reduces the energy cost of seawater desalination, pushing it past the “cost tipping point” and achieving competitiveness with tap water costs.

MMO Titanium Anode Types

Depending on coating composition, structural morphology, and application scenarios, MMO titanium anodes for seawater desalination can be divided into various types. Each type offers distinct performance advantages and is suitable for different desalination technology requirements.

Ruthenium MMO Titanium Anodes

Using a core RuO₂-TiO₂ coating system, they focus on high-efficiency chlorine evolution, achieving a 40% improvement in chlorine evolution efficiency over traditional electrodes. They are suitable for disinfection units in seawater desalination. They maintain stability in seawater with a chloride ion concentration of 10g/L, with an annual consumption rate as low as less than 1mg/A and a service life of over 15 years.

Iridium MMO Titanium Anodes

Using an IrO₂-Ta₂O₅ coating formulation, they offer excellent oxygen evolution performance and oxidative corrosion resistance. Their oxygen evolution potential is 0.2V lower than that of platinum electrodes, making them suitable for desalination pretreatment units requiring a strong oxidizing environment. This type of anode can withstand higher current densities and maintain stable operation under high load conditions of 2000A/m², making it suitable for the continuous operation requirements of large-scale desalination plants.

Platinum MMO Titanium Anode

The addition of platinum-group metals to the coating allows for dual chlorine and oxygen evolution, resulting in the highest catalytic efficiency but also relatively high cost. It is primarily used in post-desalination processes where water quality requirements are extremely high, such as pre-desalination for ultrapure water production in the electronics industry.

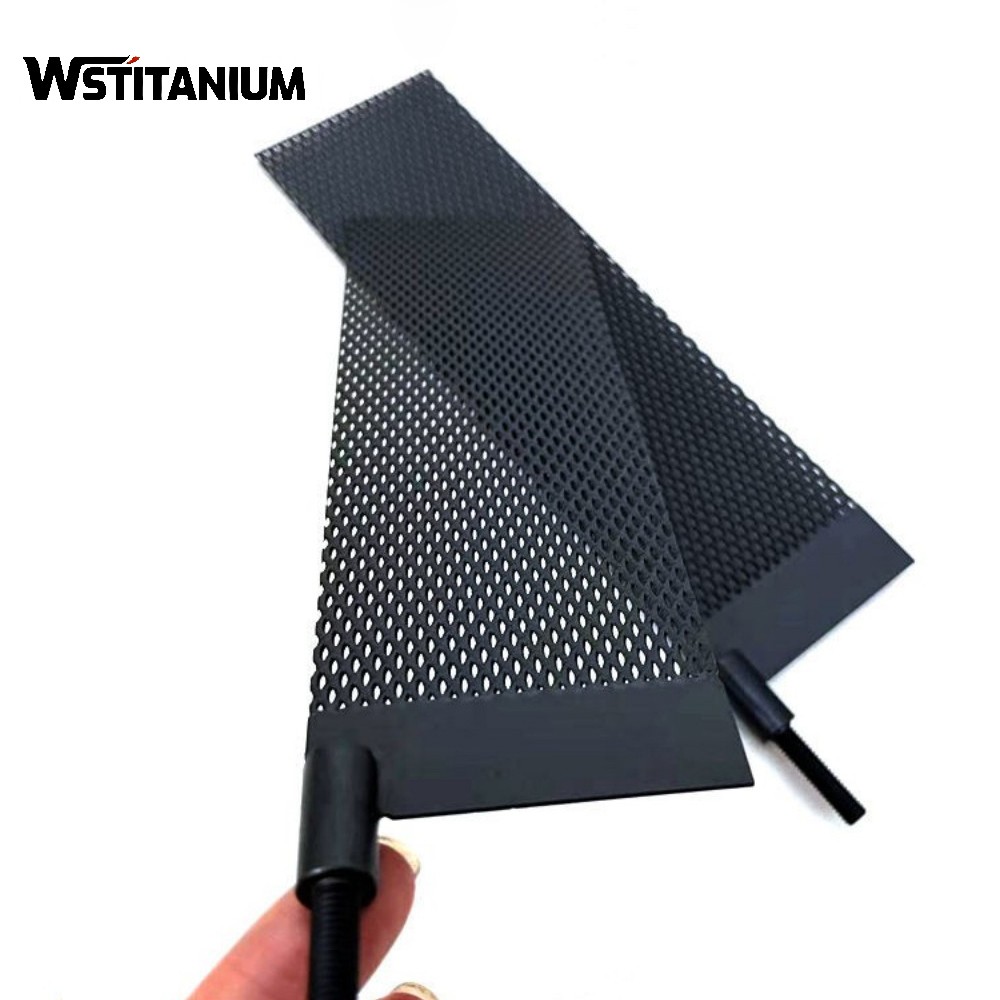

Meshed MMO Titanium Anode

Made from woven 3×50mm titanium ribbon with a mesh density of 50-200 mesh, it offers a large surface area and uniform current distribution. The porous structure created through laser engraving increases the surface area by five times and improves scale removal efficiency by 40%. Suitable for open seawater pretreatment tanks, it features easy installation and low maintenance costs, making it widely used in small and medium-sized desalination plants.

Tubular MMO Titanium Anodes

Based on a titanium tube, typically with an outer diameter of 50mm and lengths up to 6000mm, these anodes are coated with an MMO coating to create a tubular structure. Coke fillers can be added to enhance conductivity. This structure facilitates integration into pipeline desalination systems and is suitable for closed electrochemical treatment units. It is highly sought after for space-saving applications in marine desalination equipment.

Flexible MMO Titanium Anodes

Utilizing a titanium core coated with an 8mm PTFE encapsulation, the anodes have a minimum bending radius of 50mm, allowing for flexible routing along equipment contours and improving installation efficiency by three times compared to traditional plate anodes. They are suitable for complex desalination equipment or offshore desalination systems, and can withstand dynamic conditions such as turbulence and vibration.

Wstitanium has developed a library of targeted coating formulations tailored to the diverse technical requirements of seawater desalination. For the high-chlorine environments of reverse osmosis pretreatment, the ratio of RuO₂ to TiO₂ in the ruthenium-based coating is optimized, increasing chlorine evolution efficiency to over 92%. For the high-temperature environments of distillation desalination, the sintering process of the iridium-based coating has been improved, raising the coating’s temperature tolerance to 120°C, far exceeding the industry’s standard upper limit of 80°C. By precisely controlling the coating’s composition, anode energy consumption can be reduced by 22-30% in specific desalination applications, extending the anode’s service life to over 25 years.

Wstitanium has the ability to design and manufacture anodes in a full range of configurations, offering a variety of products, including mesh, tubular, and flexible structures, to meet the installation requirements of diverse desalination equipment. For large island desalination plants, we offer large-scale anode meshes woven from 3mm thick titanium ribbons, with a protective potential gradient of ≤10mV/m and 98% edge protection coverage. For ocean-going vessels, we develop miniaturized flexible anode cables with a minimum bend radius of 50mm, suitable for installation in the confined spaces of vessels. For deep-sea desalination pilot equipment, we offer specialized pressure-resistant anodes that can operate stably at pressures up to 10MPa, suitable for depths up to 3,000 meters. These products also operate in temperatures ranging from -40°C to 120°C, adapting to diverse climates from polar to tropical regions.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs