Titanium Anode For Sodium Hypochlorite

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a highly efficient and economical oxidant and disinfectant, sodium hypochlorite plays a central role in industrial production and public health. Its applications span key areas such as water treatment, medical disinfection, and food processing. Its production evolved from chemical synthesis of chlorine gas and sodium hydroxide to electrolysis of saline water. The driving force behind this technological breakthrough stemmed from innovations in electrode materials.

In the mid-20th century, the mixed metal oxide (MMO) titanium anode, a novel electrode based on a titanium matrix coated with precious metal oxides such as iridium and ruthenium, combined corrosion resistance with electrocatalytic activity, boosting the current efficiency of sodium hypochlorite production to over 85%-95%. It has become a standard core component of modern sodium hypochlorite production technology.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Applications of Sodium Hypochlorite

Due to its strong oxidizing and bactericidal properties, sodium hypochlorite has demonstrated its irreplaceable role in numerous fields. Its applications have expanded beyond traditional industries to encompass all aspects of public welfare.

(I) Water Treatment

As a core disinfectant in the water treatment industry, sodium hypochlorite holds the largest market share. In drinking water treatment, it effectively kills bacteria, viruses, and protozoa in water without producing carcinogenic byproducts such as trihalomethanes. In industrial wastewater treatment, sodium hypochlorite can oxidize and degrade toxic pollutants such as cyanide and sulfide. In circulating cooling water systems, it inhibits the growth of microorganisms and forms biosludge while also controlling pipe corrosion.

(II) Food and Pharmaceuticals

In the food processing industry, sodium hypochlorite is a recognized safe disinfectant, widely used for washing fruits and vegetables, sterilizing meat processing equipment, and sterilizing food packaging materials. In dairy production, diluted sodium hypochlorite can be used for in-situ disinfection of fermentation tanks and pipelines, killing pathogens such as Listeria, and any residues can be easily rinsed away. The pharmaceutical industry utilizes its strong oxidizing properties for pre-treatment and disinfection of medical devices, making it particularly suitable for disinfecting precision instruments in dentistry and ophthalmology.

(III) Industrial Manufacturing

In the papermaking industry, sodium hypochlorite is used as a low-cost bleaching agent for delignification of wood pulp, effectively removing colored matter from the pulp. The textile industry utilizes its oxidizing properties for desizing and bleaching cotton fabrics. In chemical synthesis, sodium hypochlorite can be used as an oxidant in various organic reactions, such as the preparation of chlorohydrins and quinone compounds.

(IV) Public Health

In public health, sodium hypochlorite is a core resource for epidemic prevention and control, and can be used for environmental disinfection in hospital wards and public places. Its diluted product is widely used for household disinfection and swimming pool water quality maintenance. Sodium hypochlorite solution (approximately 0.8% concentration) prepared on-site using MMO titanium anodes can be added directly.

Working Principle of the MMO Titanium Anode

The core of sodium hypochlorite production using the MMO titanium anode is the electrolysis of brine. Through precisely controlled electrochemical reactions, sodium chloride solution is converted into sodium hypochlorite solution.

(I) Core Reaction

Sodium hypochlorite electrolysis uses a 3%-5% sodium chloride solution as raw material. In the electrolytic cell, the MMO titanium anode and cathode form an electric field, driving directional ion migration and a redox reaction. The overall reaction equation is: NaCl + H₂O → NaClO + H₂↑. This reaction does not require high temperature or high pressure; it can proceed at room temperature and pressure.

(II) Electrode Reaction

The anode region is the key reaction site in the production of sodium hypochlorite. The high catalytic activity of the MMO coating plays a key role here. On the anode surface, chloride ions preferentially undergo oxidation: 2Cl⁻ – 2e⁻ → Cl₂↑. The efficient operation of this reaction is due to the MMO coating’s low chlorine evolution overpotential. The ruthenium-iridium oxide coating reduces the chlorine evolution overpotential by 0.2V, significantly increasing the chlorine generation rate. Furthermore, the MMO coating raises the oxygen evolution reaction potential to above 1.6V, effectively suppressing the side reaction of water molecules oxidizing to produce oxygen.

The cathode region primarily undergoes a reduction reaction. Water molecules gain electrons, generating hydrogen and sodium hydroxide: 2H₂O + 2e⁻ → H₂↑ + 2OH⁻. The sodium hydroxide produced at the cathode diffuses into the solution with the chlorine produced at the anode, resulting in a disproportionation reaction: 2NaOH + Cl₂ → NaCl + NaClO + H₂O, ultimately producing sodium hypochlorite.

(III) The Key Role of the MMO Coating

The MMO coating is formed by high-temperature sintering of metal oxides such as iridium, ruthenium, and titanium. Its nanoscale structure endows the electrode with excellent performance. The coating’s high chemical stability ensures the electrode remains resistant to dissolution and detachment in highly corrosive environments ranging from pH 2 to 12. Furthermore, its low contact resistance (only one-fifth that of a graphite anode) reduces electrical energy losses, lowering electrolysis energy consumption by over 30%. Furthermore, the coating’s high current density capability (up to 2500 A/m²) enables large-scale production within limited electrode surface areas.

MMO Titanium Anode Types

Depending on the scale of sodium hypochlorite production, equipment structure, and operating requirements, MMO titanium anodes have been developed into various types. These types differ significantly in structural design and performance, meeting the needs of a wide range of scenarios, from small-scale laboratory preparation to large-scale industrial production.

(I) Plate MMO Titanium Anodes

Plate anodes are the most commonly used type in sodium hypochlorite production. They utilize TA1 or TA2 pure titanium plates as a substrate, uniformly coated with a ruthenium-iridium MMO coating. Their advantages lie in their simple structure and ease of processing. They can be customized to suit the size of the electrolytic cell, and their uniform current distribution across the electrode surface ensures a stable sodium hypochlorite product concentration.

Plate anodes typically utilize a multi-plate assembly design, arranged in intervals to form an electrolytic unit. This structure facilitates disassembly and maintenance. Plate anodes account for over 70% of small and medium-sized sodium hypochlorite generators and are particularly well-suited for on-site preparation in hospitals and swimming pools.

(2) Tubular MMO Titanium Anodes

Tubular anodes are based on thin-walled titanium tubes, with a coating evenly covering both the inner and outer surfaces. They feature a large surface area and high mechanical strength. Their tubular structure facilitates insertion into electrolytic cells or piping systems, making them particularly suitable for continuous-flow sodium hypochlorite production equipment, ensuring sufficient contact between the solution and the electrodes and improving reaction efficiency.

Tubular MMO titanium anodes perform particularly well in integrated equipment for high-salinity wastewater treatment and sodium hypochlorite production. Their resistance to water flow shock allows them to adapt to complex fluid environments, and their lightweight design (density of only 4.5g/cm³) reduces equipment load requirements.

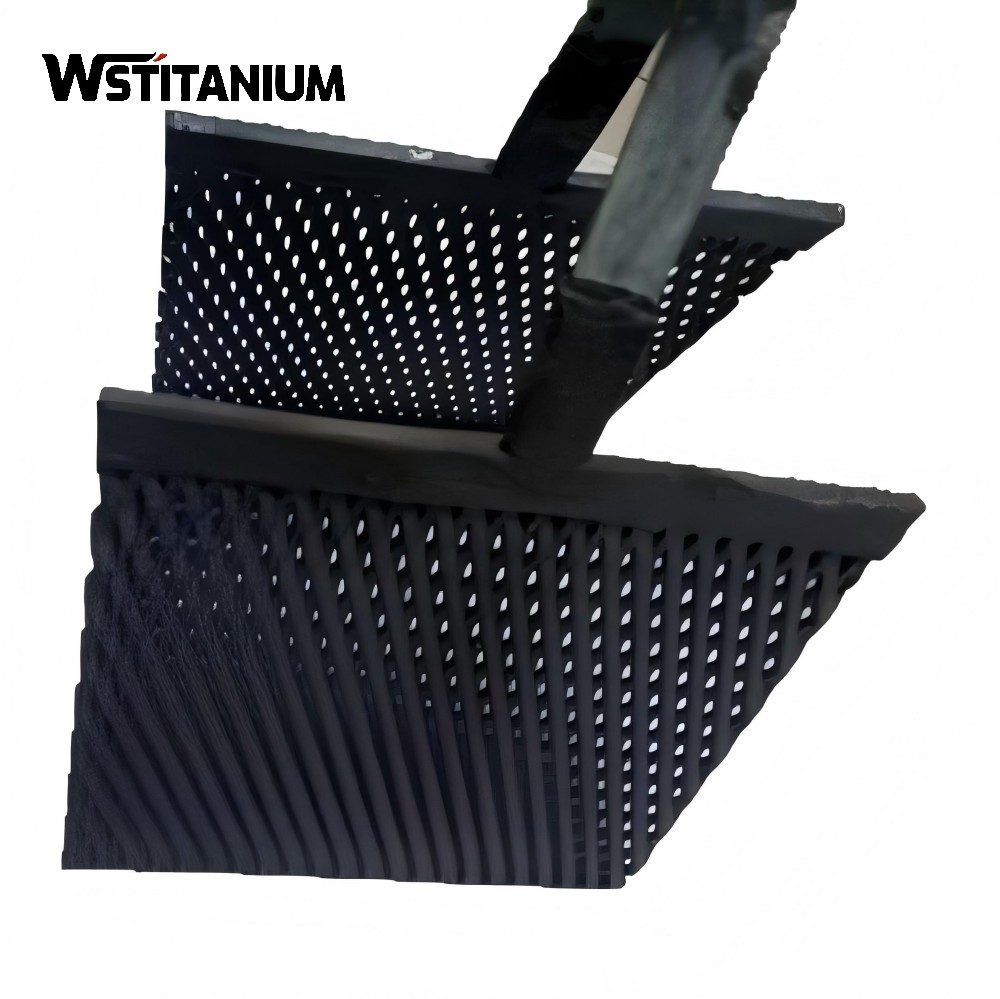

(3) Mesh MMO Titanium Anodes

Mesh anodes are made from titanium wire woven into a mesh and then coated with an MMO coating. They offer excellent flexibility and highly uniform current distribution. They can be bent into complex shapes, such as rings and spirals, to fit snugly within the walls of containers like storage tanks and reactors.

Another significant advantage of this anode type is its lightweight and ease of installation. Widely used in mobile sodium hypochlorite generators, it can significantly reduce equipment transportation costs by 42%. Its high current density carrying capacity (up to 10,000 A/m²) makes it an excellent choice for situations requiring rapid sodium hypochlorite production, such as emergency rescue operations.

(IV) Strip MMO Titanium Anodes

Strip anodes utilize a titanium ribbon substrate, with coating thickness adjustable according to current requirements, typically ranging from 0.5 to 2 mm. Their linear structure ensures uniform current distribution along their length. A single protected section can reach tens of meters, with a potential difference of less than ±0.05 V. In pipeline sodium hypochlorite production systems, ribbon anodes can be laid along the inner wall of the pipeline, creating a continuous electrolysis zone. This ensures continuous reaction during solution flow, significantly increasing product concentration.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs