Titanium Bolts For Motorcycle

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

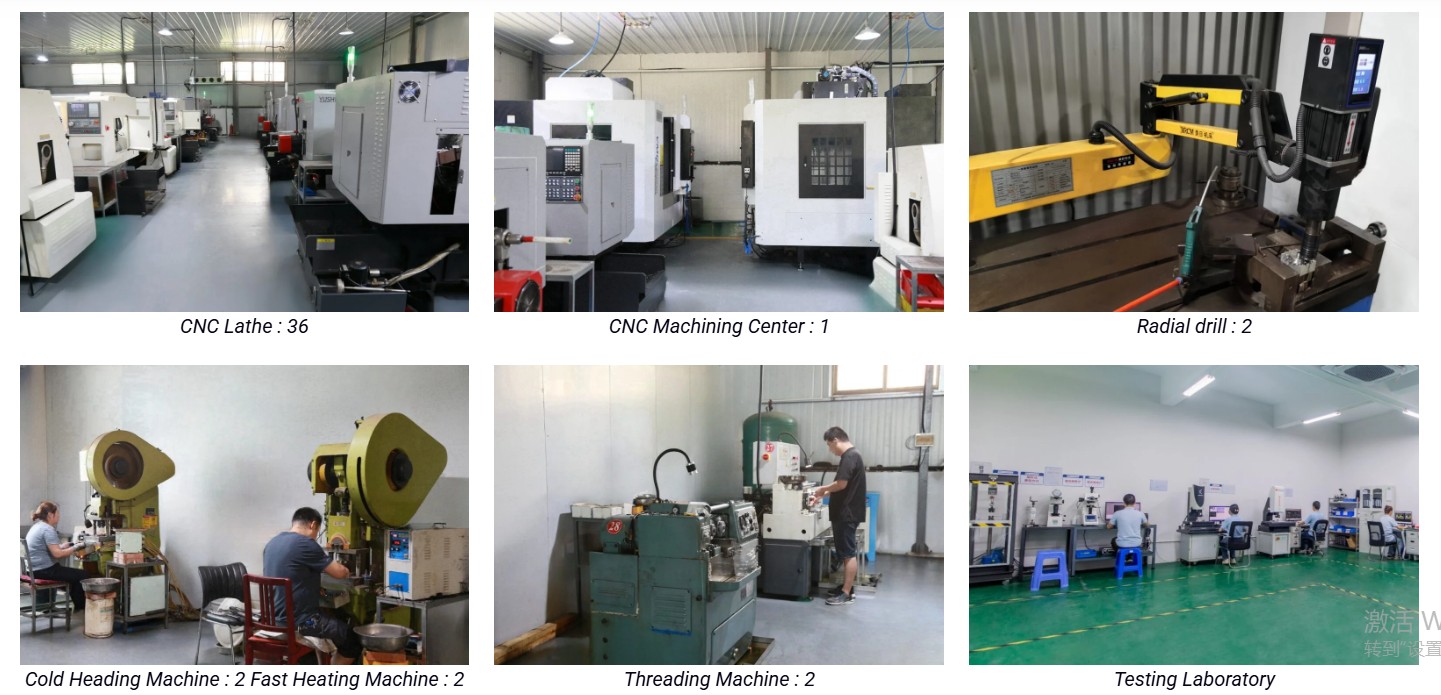

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

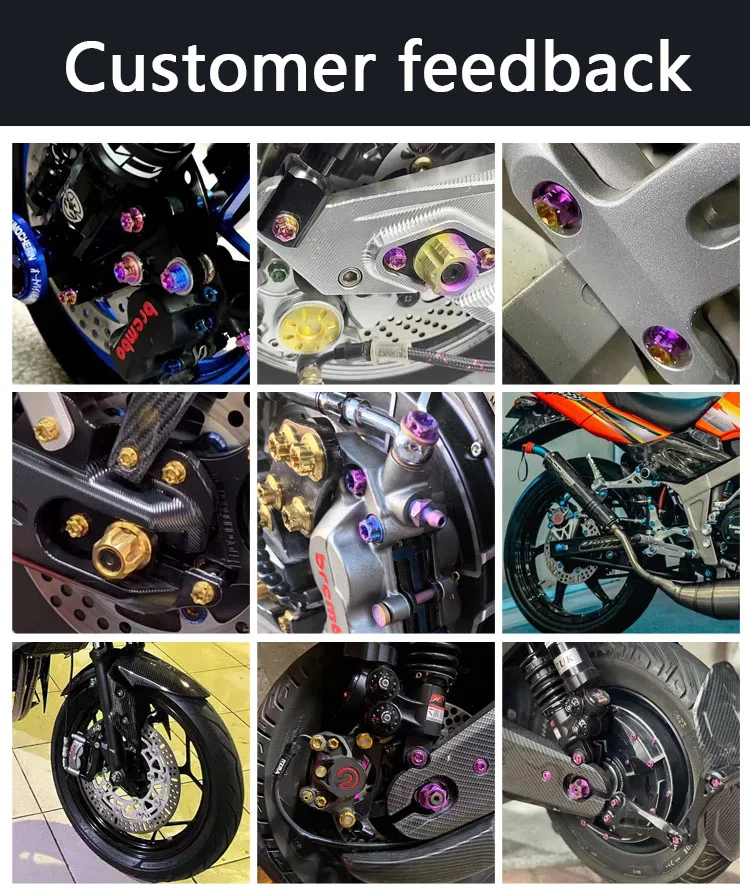

Titanium bolts, as a fastener with excellent performance, are gradually emerging in the motorcycle industry, bringing new possibilities for motorcycle performance improvement and personalized modification. Not only can it significantly reduce the weight of the vehicle and improve handling performance, but it has also become the first choice of many motorcycle enthusiasts and professional manufacturers for its excellent strength, corrosion resistance and aesthetics.

Lightweight

The density of titanium alloy is about 4.5g/cm³, which is only about 58% of the density of steel (about 7.8g/cm³), which makes titanium screws have great advantages in weight compared with traditional steel screws.

High Strength

TC4 grade titanium alloy screws commonly used in general motorcycles have a tensile strength of more than 895MPa, which is close to the strength of 10.9 grade steel screws. This means that titanium screws can withstand huge tensile and shear forces. Inside the engine, the high-speed reciprocating motion of the piston and the high-speed rotation of the crankshaft will generate huge impact and vibration. Titanium alloy screws are used to connect various parts of the engine, such as the cylinder block, cylinder head, crankcase, etc., to ensure that the structure of the engine is still stable and reliable under such extreme working conditions. In wheels, suspension, etc., titanium screws can also withstand various dynamic stresses during vehicle driving, providing solid protection for safety.

Corrosion Resistance

Titanium alloy has an innate talent for corrosion resistance. Its surface can quickly form a dense oxide film (TiO₂). This oxide film is like a solid armor, tightly attached to the surface of titanium alloy, effectively preventing external moisture, salt, oxygen and various chemicals from contacting the titanium alloy matrix, thereby greatly improving the corrosion resistance of titanium screws.

High Temperature Resistance

Titanium alloy screws show remarkable high temperature resistance and can maintain stable mechanical properties in high temperature environments up to 600°C. When the motorcycle is running at high intensity or working at high load, the engine, brake system and other components will generate a lot of heat, and the local temperature will rise sharply. With its excellent high temperature resistance, titanium alloy screws can stick to their posts in such a high temperature environment, maintain good strength and stability, ensure the installation of the brake disc firmly, and the normal operation of the brake system.

Related products

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut