Titanium Fasteners For Yachts

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As the yacht industry’s demands for safety, reliability, and high-end design continue to rise, titanium fasteners, thanks to their irreplaceable performance advantages, are becoming the preferred choice for high-end yacht manufacturing. As a professional titanium fastener manufacturer, Wstitanium has established a comprehensive technical and quality control system through dedicated expertise in three core areas: CNC precision machining, customized heat treatment, and high-performance surface treatment.

Their titanium fasteners for yachts not only achieve a high degree of material and technology compatibility, ensuring unparalleled product precision and consistency, but also possess excellent environmental adaptability and durability. Leveraging its robust customized R&D capabilities and comprehensive service offering, Wstitanium provides yacht manufacturers with high-performance, highly reliable fastener solutions.

| Size | M3-M120. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

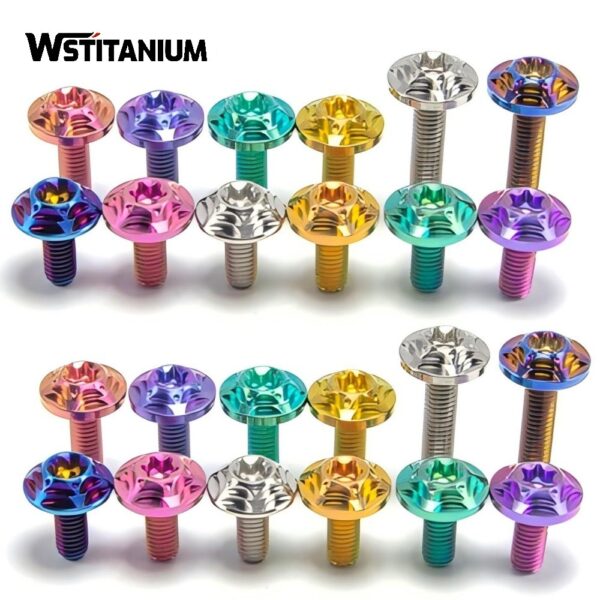

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Manufacturing Titanium Fasteners for Yachts

The manufacturing of titanium fasteners for yachts involves multiple key steps, including material selection, CNC precision machining, performance optimization, and surface modification. Wstitanium has established a comprehensive quality control system, integrating advanced technologies and experience, from raw materials to finished products. CNC machining, heat treatment, and surface treatment are the core pillars of the manufacturing process.

(I) Precision CNC Machining

CNC (Computer Numerical Control) machining technology is fundamental to achieving high-precision dimensions and complex structures in titanium fasteners. Wstitanium has developed customized CNC machining solutions tailored to the characteristics of titanium alloys.

Wstitanium is the first to be equipped with a high-precision 5-axis CNC machining center. Its multi-dimensional machining capabilities and micron-level positioning accuracy enable integrated machining of various fastener types, including bolts, nuts, and washers. For the threads commonly found in yacht fasteners, Wstitanium uses milling instead of traditional tapping. The resulting internal threads, achieving a precision of 6H, not only ensure a smooth surface finish (Ra ≤ 0.8μm) but also significantly improve thread fatigue resistance. The online inspection system uses a contact probe to measure critical workpiece dimensions (such as diameter, length, and thread pitch diameter) in real time, with an accuracy of ±0.002mm.

(II) Customized Heat Treatment

Heat treatment is a key method for regulating the mechanical properties of titanium. Wstitanium has developed multiple customized heat treatments tailored to the performance requirements of fasteners in different yacht parts, achieving a precise match of strength, toughness, and corrosion resistance.

Solution Treatment + Aging

Wstitanium utilizes a “solution treatment + aging” technology. For TC4 titanium alloy, for example, the solution treatment temperature is set at 920-950°C for 1-2 hours, followed by an aging treatment at 500-550°C for 4-6 hours. This technology increases the tensile strength of Gr5 titanium to over 1100 MPa and the yield strength to 1000 MPa.

Annealing

For titanium fasteners used in low-temperature environments for yachts, Wstitanium utilizes low-temperature annealing technology. The titanium alloy workpiece is held at 600-650°C for 3-5 hours, then furnace-cooled to room temperature. This technology eliminates internal stresses generated during processing and refines the grain size, enabling the titanium to maintain excellent toughness even at liquid nitrogen temperatures of -196°C, with an impact absorption energy of ≥40J, thus preventing low-temperature brittle fracture.

For fasteners requiring high corrosion resistance (such as bolts connecting bottom components exposed to seawater),

Vacuum annealing is performed in a vacuum environment of 10⁻³Pa, at 700-750°C for 2-3 hours, followed by slow cooling. The corrosion rate of vacuum-annealed titanium fasteners in a 3.5% sodium chloride solution is less than 0.001mm/year.

Surface Treatment

Titanium fasteners for yachts are exposed to harsh environments such as seawater, humid air, and ultraviolet light for extended periods of time. Titanium surfaces are susceptible to corrosion, wear, and biofouling. Wstitanium utilizes a variety of high-performance surface treatment technologies to significantly enhance the corrosion, wear, and biofouling resistance of titanium fasteners.

1. Pickling and Passivation

Pickling and passivation are fundamental surface treatment processes for titanium fasteners. Wstitanium uses a mixture of hydrofluoric acid and nitric acid to remove scale and surface oil, while simultaneously forming a uniform, dense oxide film (primarily composed of TiO₂) on the titanium surface. This film, approximately 5-10 nm thick, exhibits excellent chemical stability and effectively prevents contact between corrosive media such as seawater and the titanium substrate.

2. Micro-Arc Oxidation

For fasteners requiring high wear resistance, such as bolts connecting servo systems, Wstitanium utilizes micro-arc oxidation technology. This technology applies a high-voltage pulsed electric field to the titanium alloy surface, generating micro-arc discharges. Under high temperature and pressure, a ceramic oxide film with a thickness of 50-200 μm is formed. This oxide film firmly bonds to the substrate, achieving a hardness of HV800-1200 and a coefficient of friction as low as 0.15-0.25. Its wear resistance is 5-10 times greater than that of untreated titanium alloys. It also offers excellent corrosion resistance, withstanding long-term seawater erosion and wear.

3. Polytetrafluoroethylene Coating

To enhance the fastener’s anti-adhesion and biofouling properties, Wstitanium utilizes polytetrafluoroethylene (PTFE) coating technology. This coating effectively prevents marine organisms (such as barnacles and algae) from adhering to the fastener surface. The coating thickness is controlled at 10-30μm, achieving adhesion levels meeting the Class 1 standard of GB/T 9286-1998. It also exhibits excellent high and low temperature resistance (-200°C to 260°C), adapting to diverse operating environments within yachts.

4. Plasma Spraying

For specialized fasteners subject to extreme loads and wear, Wstitanium utilizes plasma spraying technology. Using an aluminum oxide-chromium oxide composite powder as the spraying material, the powder is melted in a plasma flame (temperatures exceeding 10,000°C) and sprayed onto the titanium alloy surface at high speed, forming a wear-resistant coating with a thickness of 100-300μm. This coating achieves a hardness exceeding HV1000, exhibits excellent wear resistance, and exhibits excellent resistance to high temperatures and chemical corrosion, making it suitable for fastener protection in harsh operating conditions, such as around yacht engines.

Based on your provided parameters (such as load, temperature, and corrosion environment), Wstitanium conducts material selection, structural design, technical development, and performance testing to create a customized solution. Samples are typically delivered within 7-10 business days.

Related products

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts