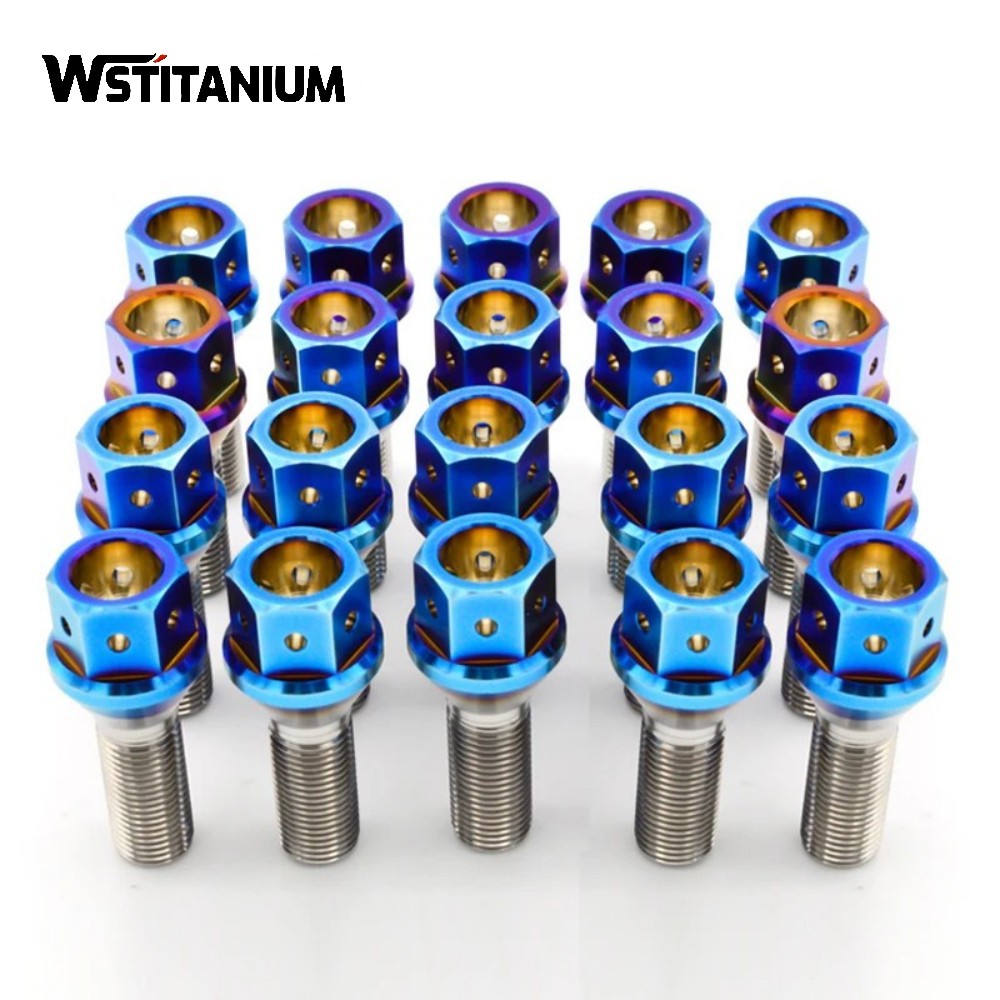

Titanium Screws and Bolts

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Titanium bolts and screws are the inevitable result of advances in materials science and manufacturing technology. Their core properties of lightweight, high strength, corrosion and wear resistance, and biocompatibility precisely meet the high-end manufacturing demands for lightweight, long life, and high reliability, driving equipment upgrades in industries such as aerospace, medical, and marine engineering.

| Size | M3-M120. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Titanium Fastener Manufacturing

The high precision of CNC machining ensures dimensional consistency in titanium fasteners. Precise control of heat treatment enables performance customization. Diversified surface treatment upgrades expand the boundaries of application. The organic combination of these three elements forms the core manufacturing system for titanium bolts and screws. Through comprehensive material control, customized technical support, rigorous quality control, and efficient service, Wstitanium contributes to the advancement of global titanium products.

CNC Machining

CNC (Computer Numerical Control) machining is a core step in the forming of titanium bolts and screws, directly determining dimensional accuracy, thread quality, and appearance consistency. CNC lathes are used to turn bolt heads and screw shafts, while CNC milling machines are used to create specially shaped head structures. CNC drilling machines are used to create detailed features such as countersunk holes and through-holes in the bolt heads, ensuring dimensional tolerances within ±0.001mm for all components.

Heat Treatment

Heat treatment is a core technology that modifies the internal microstructure of titanium alloys through controlled heating, holding, and cooling, thereby achieving precise control of mechanical properties. The application scenarios of titanium bolts and screws vary significantly. Some require high loads, while others require excellent ductility and toughness. This requires targeted heat treatment to achieve performance customization.

Annealing

Annealing is a fundamental technique in the manufacturing of titanium bolts and screws, primarily used to eliminate residual stresses generated during CNC machining and improve the material’s ductility and machinability. Common annealing methods include full annealing and stress relief annealing. Full annealing involves heating the titanium alloy to 50–100°C below the β transformation point (for example, the β transformation point of Ti-6Al-4V is approximately 996°C, so the annealing temperature is typically 920–950°C). After holding at this temperature for 1–2 hours, the alloy is cooled in the furnace to homogenize the microstructure and reduce the hardness. Stress relief annealing, on the other hand, is performed at a lower temperature (500–600°C) for 2–4 hours. This effectively eliminates residual stresses from machining and prevents deformation or cracking during subsequent use. It is particularly suitable for titanium fasteners with thin walls or complex structures.

Solution treatment and aging

For titanium bolts and screws requiring high strength (such as Ti-6Al-4V fasteners for aerospace applications), a combined “solution treatment + aging” process is often employed. Solution treatment involves heating the titanium alloy to 10-30°C above the β transformation point, holding it for a period of time, and then rapidly cooling it with water. This allows alloying elements (such as Al and V) to fully dissolve into the α phase matrix, forming a supersaturated solid solution. The subsequent aging treatment involves heating the workpiece to 450-550°C after solution treatment and holding it for 4-8 hours. This promotes the precipitation of fine β phase particles from the supersaturated solid solution, significantly improving the material’s strength and hardness through dispersion strengthening. For example, after solution aging treatment, the tensile strength of Ti-6Al-4V can be increased from 895 MPa in the annealed state to over 1100 MPa, and the yield strength from 825 MPa to over 1000 MPa, fully meeting the strength requirements of fasteners for high-end equipment.

β Heat Treatment

β heat treatment is a specialized technology for highly alloyed titanium alloys, such as Ti-10V-2Fe-3Al. Heating the workpiece above the β-transformation point, holding the temperature, and then slowly cooling it produces a coarse β-grain structure. Combined with subsequent aging treatment, this improves the fracture toughness of the material while maintaining high strength, making it suitable for titanium bolts subjected to impact loads.

Surface Treatment

Titanium alloys inherently possess excellent corrosion resistance, but in specific applications (such as crevice corrosion in marine environments and the bioactivity requirements of medical implants), surface treatment is required to further enhance performance.

Anodizing

Anodizing is a process in which an electric current is applied to the titanium fastener in an acidic electrolyte (such as sulfuric acid or oxalic acid) to form a titanium oxide film on the surface. This film, typically 0.5 to 10 μm thick, not only enhances corrosion resistance but also improves surface wear resistance and electrical insulation. The film color (e.g., natural, blue, or gold) can be controlled by adjusting the electrolyte composition and voltage to meet decorative requirements.

Passivation

Passivation involves forming a thin, dense oxide film on the titanium surface through chemical methods (such as immersion in nitric acid or chromate solutions) to enhance corrosion resistance. Compared to anodizing, the passivation film is thinner (typically less than 0.1μm), yet it offers low cost, high efficiency, and suitability for mass production.

Coatings

For specialized service requirements, titanium bolts and screws can also be upgraded through coating technology.

Wear-resistant coatings, such as titanium nitride (TiN) coatings, deposited via physical vapor deposition (PVD), can achieve hardnesses exceeding 2000 HV and significantly improve the wear resistance of fasteners, making them suitable for high-frequency disassembly.

Solid lubricant coatings, such as polytetrafluoroethylene (PTFE) coatings, offer a low coefficient of friction (0.05–0.1), reducing friction during bolt-nut assembly.

Bioactive coatings, such as hydroxyapatite (HA), can be applied to the surface of titanium bolts used for medical implants to mimic bone tissue composition, promoting osseointegration and shortening healing time.

Wstitanium can adjust CNC machining parameters for specialized sizes (such as micro titanium screws with a diameter of 0.5mm and extra-long titanium bolts up to 500mm in length). Heat treatments are optimized to meet specific performance requirements, such as customizing cryogenic treatments for fasteners used in low-temperature environments to enhance low-temperature toughness. Wstitanium is equipped with advanced equipment, including a high-precision CNC machining center (positioning accuracy of ±0.005mm), a vacuum heat treatment furnace (temperature control accuracy of ±5°C), and PVD coating equipment. Wstitanium integrates quality control throughout the entire manufacturing process and has established a quality assurance system compliant with ISO 9001 and ISO 13485 (Medical Device Quality Management System), ensuring that every titanium bolt and screw meets stringent standards.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Rainbow Titanium Bolt For Cars