ICCP MMO Flexible Anode

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Impressed current MMO linear anodes, as a core product in the field of cathodic protection technology, have become the preferred anode material for corrosion protection of metal structures due to their excellent electrocatalytic activity, extremely low consumption rate, good mechanical properties, and wide environmental adaptability.

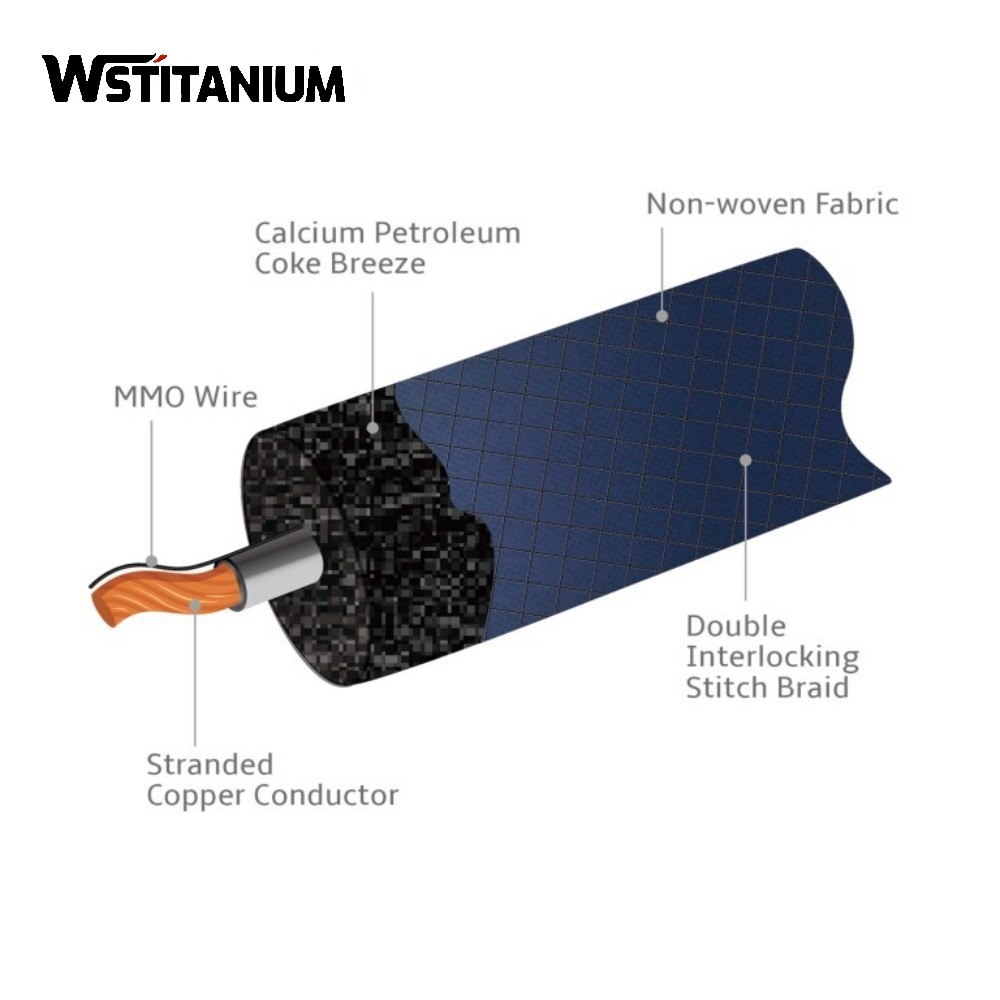

Their structural design integrates the synergistic effects of the core conductor, MMO coating, insulating sheath, connecting components, and auxiliary components. MMO linear anodes have been widely applied in various fields such as long-distance buried pipelines, large storage tank bottom plates, marine engineering structures, and industrial structures and equipment.

For engineering technicians, when selecting and applying MMO linear anodes, it is necessary to consider factors such as the specific corrosion environment, the characteristics of the protected structure, and the design life, rationally select product specifications, optimize installation schemes, and match the impressed current system to ensure that the cathodic protection effect achieves the expected results.

Specification

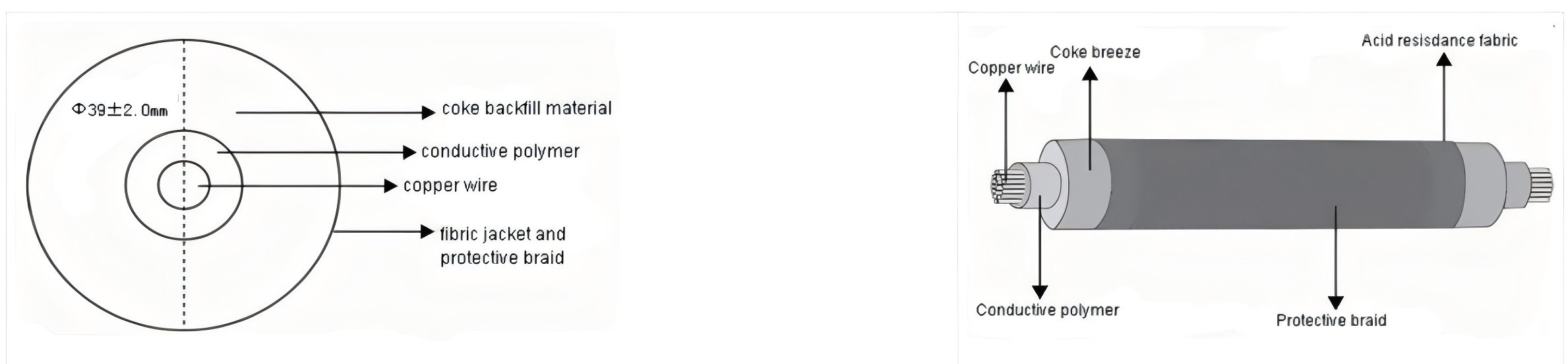

| Technical parameters | TB39-52 |

| Anode diameter | 39±2mm |

| Conductive polymer average thick | ≥4mm |

| Conductive polymer volume resistance | 1.5Ω.cm |

| In the 1mol/L sulfuric acid solution, 50 times of the normal current for electrolysis experiment | ≥14 days |

| Put the 0.2 meter sample into the NaCl solution whose quality percentage is 3%,add 40mA current,test for a month | Consumption of coke breeze is 3% of radius of the visible inlet ring |

| Output current(max) | 1500mA/m |

| Anode design life | ≥40 years |

| Content of Coke breeze filler | ≥ 98% |

| Coke breeze resistance | ≤0.55 Ω·cm |

| Fabric jacket tube | Anticorrosion,permeable |

| Fabric jacket mesh | Wearproof,anti environmental temperature variability |

| Anode weight | ≥1.3kg/m |

| Anode length(each unit) | 500m(or made to order) |

| Material | Environment | Testing item | Typical value |

| Copper wire | 20℃ | Resistance | 1.55×10¯³Ω∕m |

| Conductive polymer | 23℃ | Resistance rate | 1.5Ω.cm |

| 23℃ | Tensile strength | 13 | |

| 23℃ | Rupture and elongation rate | 350 | |

| Coke packing layer | 23℃ | Resistance rate | 0.5Ω.㎝ |

| Carbon content | 99.5% | ||

| Acid and alkali proof weaving layer | 23℃ | Rupture intensity | 980N |

| Wear proof weaving web | In different electrolyte environment for 6 months | Tensile strength changes less than 20 % | |

Technical parameters are the core indicators for evaluating the performance of MMO linear anodes, directly determining their applicability and operational effectiveness in cathodic protection systems. The following are key technical parameters commonly used in the industry. Different manufacturers may optimize their products according to application requirements, but they must comply with relevant international standards (such as ASTM G97 and ISO 15589).

(I) Electrical Performance Parameters

**Operating Current Density:** This refers to the current intensity output per unit surface area of the anode, a key parameter determining anode lifespan and protective effectiveness. The rated operating current density of MMO linear anodes is typically 10-50 A/m². In practical applications, it can be adjusted based on factors such as the corrosion rate of the protected structure and the conductivity of the surrounding medium. The maximum allowable current density can reach 100 A/m² (short-term overload). Current density selection must balance protection requirements and anode lifespan; excessively high current densities will accelerate coating wear and reduce anode lifespan.

**Polarization Rate:** This refers to the voltage drop change of the anode under operating current, reflecting the electrocatalytic activity of the anode. MMO linear anodes exhibit extremely low polarization, typically below 100 mV/A·m, far superior to graphite anodes (500-1000 mV/A·m) and high-silicon cast iron anodes (300-800 mV/A·m).

Grounding resistance: This refers to the resistance between the anode and the surrounding electrolyte, directly affecting the power requirements of the cathodic protection system. The grounding resistance of MMO linear anodes is typically 1-10 Ω·m. By appropriately selecting backfill materials and installation methods, the grounding resistance can be further reduced, improving current output efficiency.

Open circuit potential: This refers to the electrode potential of the anode in the unenergized state, reflecting the anode’s chemical stability. The open circuit potential of MMO linear anodes is typically 0.8-1.2 V (relative to a saturated calomel electrode, SCE), remaining stable in soil or seawater without spontaneous corrosion.

Consumer rate: This refers to the mass loss of the anode per unit current and unit time, a core indicator for measuring anode lifespan. The consumption rate of the MMO coating is extremely low, typically less than 0.01 g/A·a, and the consumption rate of the core conductor (titanium alloy) is negligible. Therefore, the design life of MMO linear anodes can reach 20-50 years, far exceeding that of traditional anodes (graphite anodes have a lifespan of 5-10 years, and high-silicon cast iron anodes have a lifespan of 10-15 years).

(II) Mechanical Performance Parameters

Tensile Strength: Reflects the anode’s ability to resist tensile failure, ensuring that it does not break under construction drag and soil stress. The tensile strength of MMO linear anodes is typically ≥300 MPa. The tensile strength of the core conductor (titanium alloy wire) is ≥450 MPa.

Bending Radius: Reflects the flexibility of the anode, facilitating installation in complex paths. For linear anodes with a diameter of 1.5-2.0 mm, the minimum bending radius is typically ≤50 mm, adaptable to pipe loops, irregular tank bottom plate arrangements, etc.

Abrasion Resistance: Refers to the abrasion resistance of the insulating sheath, preventing scratches from sand, gravel, or sharp objects in the soil during construction. The abrasion resistance of the HDPE insulating sheath conforms to ASTM D4060 standard, with an abrasion amount ≤0.5g (1000 revolutions, 1kg load).

Impact Resistance: Refers to the insulating sheath’s ability to resist impact damage, ensuring no cracking occurs during construction hoisting and soil compaction. The impact strength (Izod notched impact test) of the insulating sheath is ≥40kJ/m² (23℃), and ≥20kJ/m² at low temperatures (-20℃).

(III) Environmental Adaptability

Temperature Range: MMO linear anodes have a wide applicable temperature range. Conventional products can operate stably between -40℃ and 80℃. Special modified products (such as high-temperature coating + fluoroplastic sheath) can withstand high-temperature environments above 120℃, suitable for geothermal wells, industrial high-temperature media, and other scenarios.

Media Compatibility: Suitable for use in various media including soil (acidic, alkaline, saline, and swampy soils), seawater, freshwater, industrial wastewater, and concrete. It exhibits good resistance to corrosive ions such as sulfides and chloride ions.

Voltage Withstand Performance: The insulation sheath must meet the system’s operating voltage requirements. The breakdown voltage of standard products should be ≥20kV/mm, ensuring no leakage or insulation breakdown occurs at the rated operating voltage (typically 12-30V).

Aging Resistance: The insulation sheath and coating must possess excellent UV resistance and oxidation resistance, with a service life ≥20 years in outdoor or long-term exposure environments without cracking, discoloration, or performance degradation.

(IV) Dimensional Specifications

Anode Diameter/Width: The diameter of round MMO linear anodes is typically 1.0-3.0mm (core conductor diameter 0.8-2.5mm, coating thickness 20-50μm, insulation sheath diameter 3-10mm); the width of flat strip anodes is 3-10mm, and the thickness is 1.0-3.0mm (including the insulation sheath).

Standard Length: The standard length of a single anode is typically 50m, 100m, or 200m, and can be customized according to project requirements, up to a maximum of 500m.

Connector Dimensions: The dimensions of the anode connectors and cable connectors must match the anode specifications, typically φ5-10mm (round connectors) or 3×5mm-10×15mm (flat strip connectors), ensuring a tight connection and convenient installation.

With its excellent comprehensive performance, MMO linear anodes have been widely used in cathodic protection projects for various metal structures, covering multiple fields such as petrochemicals, municipal construction, marine engineering, and power industry, becoming the core choice for corrosion protection projects in long-distance, large-area, and complex environments.

Related products

-

Impressed Current Cathodic Protection

ICCP MMO Linear Anodes

-

Impressed Current Cathodic Protection

ICCP MMO Tubular Anode